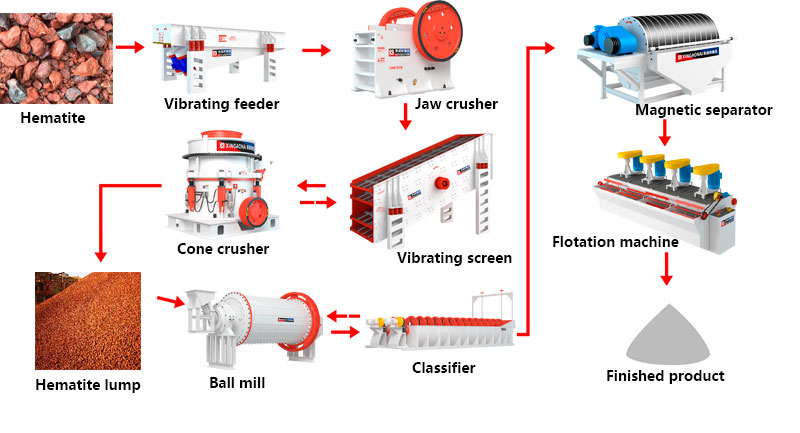

Hematite is the most important iron ore, with an iron content of up to 70% and wide distribution. It is the core raw material for iron smelting, and can also be used as red pigment and abrasive. A professional hematite processing solution is crucial to maximizing iron recovery rate, reducing metal loss, and improving economic benefits. We tailor a targeted hematite beneficiation process based on hematite’s physical properties (heavy, hard, often associated with magnetite), integrating stage grinding, magnetic separation, flotation, and reverse flotation technologies to achieve efficient ore separation.

Core Technologies of Hematite Processing Solution

Our hematite beneficiation process adopts a scientific combination of technologies to address the mineral characteristics of hematite:

Stage Grinding & Classification: Uses a ball mill and cyclone to form a closed-circuit grinding system, ensuring classification efficiency and particle size accuracy. Qualified concentrates can be sorted in advance, while low-grade tailings are discarded via high-gradient magnetic separators—reducing regrinding volume and avoiding over-grinding.

Magnetic-Flotation Combined Process: Magnetic separation first separates coarse-grained qualified concentrates and tailings (adhering to the "early harvest and early abandonment" principle), reducing flotation workload and costs. Strong magnetic technology recovers fine-grained iron minerals, realizing desliming and tailing disposal to create favorable conditions for flotation.

Reverse Flotation Process: Features a simple chemical system, minimizing the entry of organic flotation reagents into the slurry and reducing adverse impacts on the separation effect—ensuring high concentrate purity.

Key Equipment Configuration for Hematite Beneficiation

The hematite processing solution is composed of professional equipment to ensure stable operation and efficient separation:

Feeding & Crushing: Vibrating feeder, jaw crusher, cone crusher (for coarse crushing of hematite lumps)

Grinding & Classification: Ball mill, classifier (cyclone)

Separation Equipment: High-gradient magnetic separator, flotation machine

Auxiliary System: Slurry pump, pipeline, control system (real-time monitoring of process parameters)

Core Advantages of Our Hematite Processing Solution

High Iron Recovery Rate: Targeted process design improves hematite recovery by 10-15% compared to traditional methods, maximizing resource utilization.

Efficient Separation: Stage grinding + magnetic-flotation combined technology avoids over-grinding, reducing metal loss and improving concentrate quality.

Cost-Effective Operation: "Early tailing abandonment" reduces processing volume, while the simple reverse flotation chemical system cuts reagent costs.

Customizable Design: Adaptable to different hematite ore properties (e.g., association with magnetite) and production capacity requirements.

Application Scenarios of Hematite Beneficiation Process

Our hematite processing solution is widely applied in iron ore mining and smelting projects worldwide:

Large-scale hematite mines: Realizes continuous, automated beneficiation to meet industrial iron smelting demand.

Iron smelting enterprises: Provides high-purity hematite concentrates to ensure stable smelting quality.

Small-to-medium ore processing plants: Modular equipment configuration adapts to limited site and capacity needs.

Customized Hematite Processing Solution for Your Project

We do not offer one-size-fits-all solutions. Instead, we tailor the hematite beneficiation process based on your actual needs:

Conduct on-site ore testing to analyze hematite properties (iron content, associated minerals, particle size).

Design process flow and equipment configuration according to your production capacity and concentrate quality requirements.

Provide full-process services: equipment manufacturing, installation, commissioning, and operator training.

Offer long-term after-sales support and spare parts supply to ensure stable operation of the production line.

Whether you are a large mining enterprise or a medium-sized ore processor, we can provide a tailored hematite beneficiation process to meet your production goals. Partner with us to maximize the economic benefits of your hematite resources.