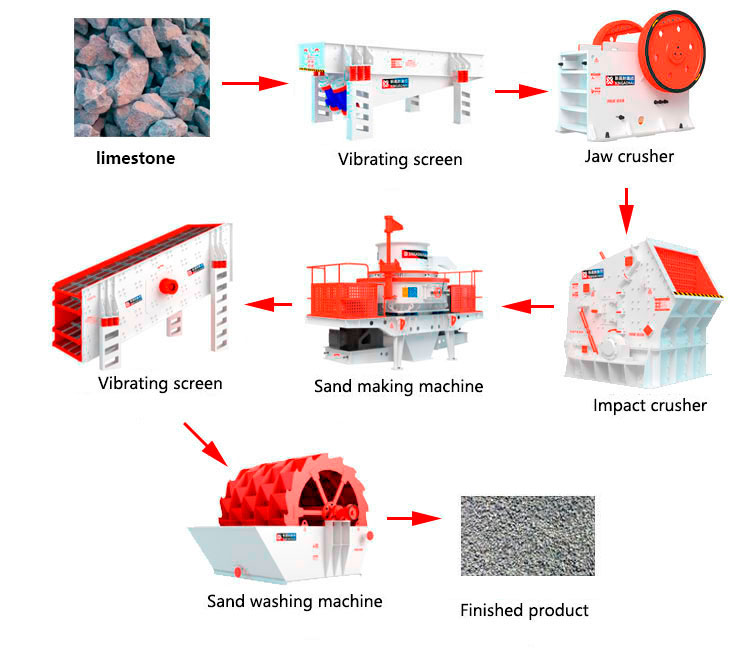

Limestone is one of the most widely used non-metallic minerals in construction, road building, cement manufacturing and aggregate production industries. A professional limestone crushing solution is the core to realize high-efficiency, low-cost and high-quality limestone processing, which directly determines the production capacity, product gradation and economic benefits of quarry and mining enterprises. We provide a customized limestone crushing solution for limestone characteristics—combining multi-stage crushing, screening and shaping equipment to meet the processing needs of different limestone applications, from raw ore crushing to finished aggregate output. This solution is designed for the physical properties of limestone (medium hardness, low abrasion, good crushability) to maximize processing efficiency and reduce operational costs.

Core Configuration of Our Limestone Crushing Solution

Our complete limestone crushing solution is a modular combination of professional equipment, which can be flexibly adjusted according to your production capacity (50-2000 TPH) and finished product requirements (0-5mm sand, 5-10mm, 10-20mm aggregate). The standard configuration includes:

Key Advantages of Our Limestone Processing Solution

Targeting the processing characteristics of limestone, our limestone crushing solution has obvious competitive advantages in efficiency, cost and environmental protection:

✅ High production efficiency & low energy consumption

Adapted to limestone’s medium hardness, the equipment combination reduces energy consumption per ton of finished products by 15-20% compared with the traditional crushing line, and the modular design shortens the material conveying distance to improve overall production efficiency.

✅ Customizable product gradation

The solution can be flexibly adjusted according to your demand for finished products, whether it is construction aggregate, cement raw material or machine-made sand, to achieve one-line multi-purpose and maximize the utilization rate of limestone resources.

✅ Eco-friendly & low dust emission

Equipped with professional dust removal and noise reduction equipment, the closed production line effectively controls dust and noise, complying with the environmental protection regulations of mining and construction industries worldwide, and realizing green limestone processing.

✅ Stable operation & easy maintenance

All equipment adopts wear-resistant and durable components, with a simple structure and convenient maintenance. The whole line is equipped with an intelligent control system, which can realize real-time monitoring of equipment operation and reduce downtime caused by failure.

Application Scenarios of Limestone Crushing Solution

Our limestone crushing solution is widely applicable to various limestone processing fields, and has been successfully applied in quarry, cement plant and construction engineering projects around the world:

➤ Construction aggregate production: Process limestone into graded aggregate for road, bridge, high-speed railway and building foundation construction.

➤ Cement manufacturing: Provide uniformly crushed limestone raw material for cement production line, ensuring the stability of cement quality.

➤ Machine-made sand production: Convert limestone into high-quality machine-made sand to replace natural sand and solve the shortage of sand resources.

➤ Quarry mining: Realize large-scale, continuous and automated limestone crushing and screening, improving the economic benefits of quarry enterprises.

Tailored Limestone Processing Solution for Your Project

There are great differences in limestone ore properties, production capacity and finished product requirements of different projects. We do not provide a one-size-fits-all limestone crushing solution, but customize the most suitable processing line according to your actual situation:

✔ Conduct on-site investigation of your quarry/plant to understand the ore properties and site conditions.

✔ Design the equipment combination and process flow according to your production capacity and finished product standards.

✔ Provide full-process services including equipment manufacturing, installation, commissioning and operator training.

✔ Offer long-term after-sales support and spare parts supply to ensure the stable operation of the production line.