Granite is a premium building material renowned for its uniform structure, high hardness, aesthetic appeal, and durability. It is widely used in construction (from roofing to flooring), outdoor sculpture, decorative panels, and aggregate production. To unlock its full value, a professional granite crushing solution is essential—tailored to granite’s high-hardness characteristics (Mohs hardness 6-7) to ensure efficient crushing, uniform particle size, and high-quality finished products. Our custom granite processing line integrates multi-stage crushing, screening, shaping, and cleaning equipment, meeting diverse needs from construction aggregates to decorative stone processing.

Core Process of Granite Crushing Solution

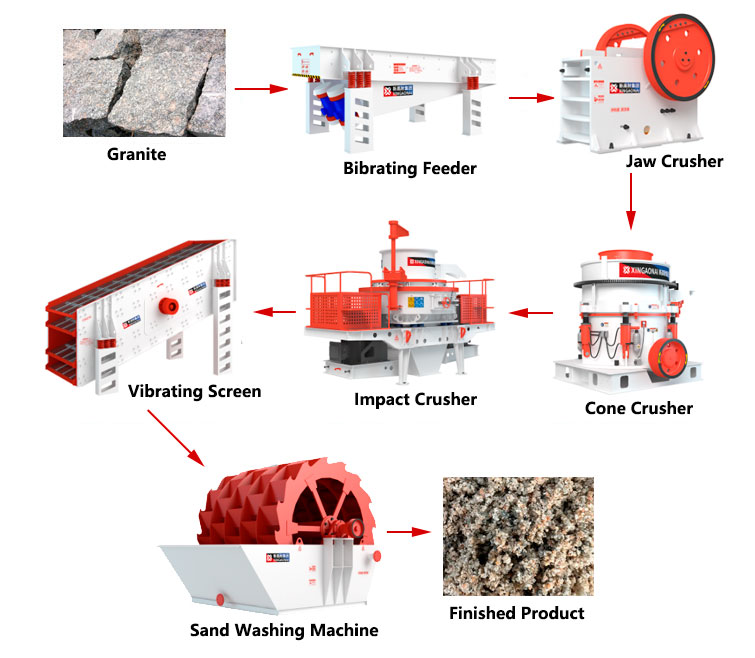

The granite crushing solution follows a scientific three-stage process to handle granite’s hardness and ensure optimal output:

Coarse Crushing: Large granite blocks are evenly fed via a vibrating feeder from the silo to a jaw crusher. This step reduces raw granite (up to 1000mm) into coarse particles, laying the foundation for subsequent processing.

Medium & Fine Crushing: Coarsely crushed granite is screened by a vibrating screen, then transported via belt conveyor to an impact crusher or cone crusher for medium and fine crushing. Oversized particles from screening are recycled back to the crusher for reprocessing, ensuring uniform particle size.

Shaping & Cleaning: The crushed granite is sent to a sand making machine for further crushing and cubical shaping—enhancing aggregate quality for construction use. If clean granite products are required, the material is transferred to a sand washing machine to remove dust and impurities.

Key Equipment Configuration for Granite Processing Line

Our granite crushing solution is equipped with wear-resistant, high-efficiency equipment to adapt to granite’s hardness:

Feeding Equipment: Vibrating feeder (ensures uniform feeding, prevents crusher overload)

Crushing Equipment: Jaw crusher (coarse crushing), impact crusher/cone crusher (medium & fine crushing)

Shaping Equipment: Sand making machine (optimizes particle shape, produces cubical aggregate)

Screening Equipment: Vibrating screen (grades particles, ensures product uniformity)

Cleaning Equipment: Sand washing machine (removes impurities, delivers clean finished products)

Conveying Equipment: Belt conveyor (connects each process, ensures continuous operation)

Core Advantages of Our Granite Crushing Solution

Targeting granite’s high-hardness and processing needs, our granite crushing solution offers distinct competitive edges:

High Efficiency & Wear Resistance: Equipment is fitted with wear-resistant components (high-chromium alloy hammerheads, manganese steel liners) to withstand granite’s abrasiveness, reducing maintenance downtime by 20-30%.

Uniform & High-Quality Output: Multi-stage crushing + shaping process produces cubical aggregates (flakiness rate ≤10%) and consistent particle gradation, meeting construction and decorative material standards.

Customizable Design: The line can be adjusted based on production capacity (50-2000 TPH) and finished product requirements (0-5mm sand, 5-20mm aggregate, decorative panels).

Eco-Friendly Operation: Closed-loop design + dust removal equipment controls dust emission, complying with global environmental regulations for quarry and construction industries.

Stable & Easy Maintenance: Simplified equipment structure and intelligent monitoring system enable real-time operation tracking, reducing failure risks and maintenance costs.

Application Scenarios of Granite Crushing Solution

Our granite processing line is widely applied in global quarry, construction, and decoration projects:

Construction Aggregates: Produces graded granite aggregate for roads, bridges, high-speed railways, and building foundations—enhancing structural durability.

Decorative Stone Processing: Processes granite into decorative panels, floor tiles, and outdoor sculpture materials, leveraging its aesthetic appeal and weather resistance.

Cement Manufacturing: Converts granite into raw material for cement production, ensuring stable cement quality.

Quarry Mining: Enables large-scale, automated granite crushing and screening, improving quarry operational efficiency and economic benefits.

Customized Granite Crushing Solution for Your Project

We recognize that granite ore properties, production capacity, and finished product demands vary by project. Instead of one-size-fits-all solutions, we offer tailored granite crushing solution:

Conduct on-site quarry investigations to analyze granite hardness, particle size, and site conditions.

Design equipment combinations and process flows based on your production capacity and product standards.

Provide full-process services: equipment manufacturing, on-site installation, commissioning, and operator training.

Offer long-term after-sales support and genuine spare parts supply to ensure stable line operation.

Whether you operate a large quarry, a construction aggregate plant, or a decorative stone factory, we can deliver a tailored granite crushing solution to meet your production goals. Partner with us to build a high-efficiency granite processing line and unlock greater economic value from your granite resources.