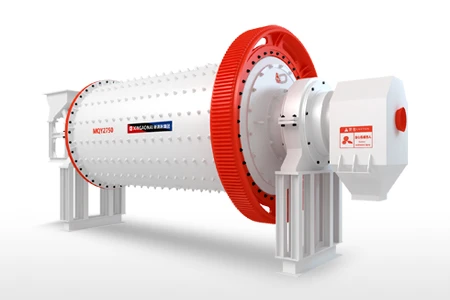

What Is a Ball Mill? Core Definition

The primary goal of a ball mill is to achieve a specific particle size distribution, which varies depending on the application—from coarse grinding for pre-processing ores to ultra-fine grinding for pharmaceutical ingredients or advanced materials. Its ability to handle large volumes of material and adapt to different feed properties is what makes it a staple in many industrial workflows.

How Does a Ball Mill Work? The Working Principle

Feeding Stage: The raw material (known as the “feed”) is introduced into the ball mill through a hollow trunnion at one end of the cylindrical shell. The feed can be in the form of lumps, granules, or even small particles, depending on the pre-processing steps. For wet grinding, water or a liquid medium is often added along with the feed to facilitate grinding and prevent dust.

Grinding Stage: The cylindrical shell is driven by a motor and gear system, causing it to rotate at a specific speed (typically 40–70% of the critical speed, the speed at which the grinding media would stick to the shell wall and not fall). As the shell rotates, the grinding media inside are lifted to a certain height by centrifugal force and then fall back down due to gravity. This repeated lifting and dropping create impact forces that crush the feed material. Additionally, the sliding and rolling of the grinding media against each other and the shell wall generate attrition forces, which grind the material into finer particles.

Discharging Stage: Once the material reaches the desired particle size, it is discharged from the ball mill through a hollow trunnion at the opposite end of the feed. In some designs, a screen or classifier is used to ensure only particles of the required size exit, while larger particles are recirculated back into the mill for further grinding.

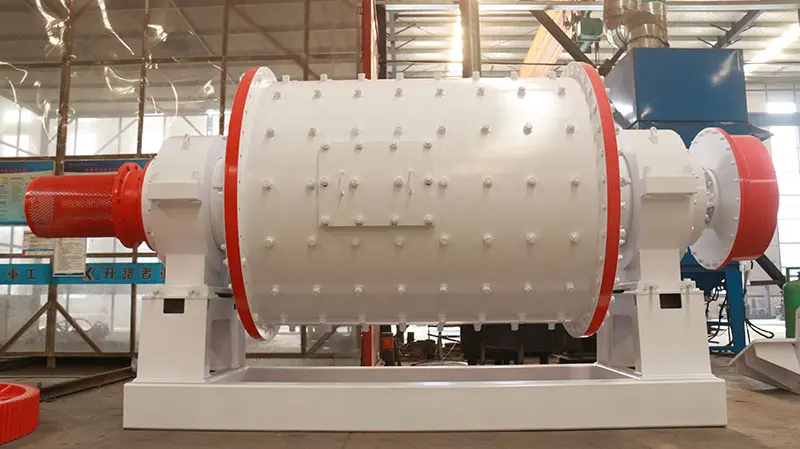

Key Components of a Ball Mill

Cylindrical Shell: The main body of the mill, usually made of steel or cast iron, which holds the grinding media and feed material. The inner surface of the shell may be lined with wear-resistant materials (such as manganese steel or rubber) to protect it from abrasion.

Grinding Media: The “balls” or other objects that cause grinding. Common types include steel balls (for hard materials), ceramic balls (for contamination-free grinding), and pebbles (for low-cost applications). The size and quantity of the grinding media are tailored to the feed material and desired output.

Trunnions: Hollow cylindrical shafts at both ends of the shell that allow for feeding and discharging. They also support the weight of the shell and its contents, resting on bearings for smooth rotation.

Drive System: Composed of a motor, gearbox, and pinion gear that drives the shell. The motor provides power, while the gearbox adjusts the speed to ensure optimal grinding efficiency.

Liner: A replaceable layer inside the shell that reduces wear and tear. Liners can be designed with different shapes (e.g., smooth, ribbed) to enhance grinding performance.

Common Types of Ball Mills

Overflow Ball Mill: The most common type, where the discharge trunnion is lower than the centerline of the shell. Material is discharged by overflowing, making it suitable for fine grinding. It’s widely used in mineral processing and cement production.

Grid Ball Mill: Equipped with a grid at the discharge end to control the particle size. The grid prevents large particles from exiting, ensuring more uniform grinding. It’s often used for coarse to medium grinding in mining operations.

Tube Mill: A long, cylindrical ball mill divided into multiple chambers with different-sized grinding media. Each chamber handles a specific grinding stage, from coarse to fine. It’s ideal for producing ultra-fine powders in industries like ceramics and pharmaceuticals.

Attritor Mill: A vertical ball mill where the grinding media are stirred instead of the shell rotating. It’s compact and efficient for small-scale grinding, commonly used in laboratories and specialty chemical production.

Industrial Applications of Ball Mills

Mining and Mineral Processing: Ball mills are used to grind ores (e.g., gold, copper, iron) into fine particles for subsequent separation processes like flotation or leaching. They are a critical part of the mineral extraction workflow.

Cement Production: In cement plants, ball mills grind clinker (a hard, nodular material) with gypsum to produce cement powder. This grinding step is essential for determining the strength and quality of the final cement product.

Ceramics and Glass: Ball mills grind raw materials (e.g., clay, silica) into uniform powders that are used to make ceramic products, glass, and refractories. The fine particle size ensures consistent texture and quality in the finished goods.

Chemical and Pharmaceutical Industries: Ball mills are used to grind chemicals, pigments, and pharmaceutical ingredients into fine powders for use in medications, dyes, and specialty chemicals. Ceramic or rubber liners are often used here to avoid contamination.

Construction Materials: They grind materials like limestone, slag, and fly ash into powders used in concrete admixtures and other construction products, improving their performance and durability.