Fluorite, formed from volcanic magma remnants, is a critical mineral rich in fluorine. It is the primary source of industrial fluorine and widely used as a flux in steelmaking (to remove impurities), raw material for glass and enamel production, and a key component in optical lenses—thanks to its low dispersion and minimal chromatic aberration. To unlock its full value, a specialized fluorite beneficiation process is essential, focusing on separating fluorite from associated minerals (barite, quartz, sulfide ore) via targeted flotation technology. Our custom fluorite processing solution is tailored to mineral characteristics, delivering high-grade fluorite concentrate that meets strict industrial standards.

Core Beneficiation Processes of Fluorite Processing Solution

Fluorite often coexists with barite, quartz, and sulfide ore, requiring precise separation processes to obtain pure concentrate:

Separation of Fluorite and Barite:

First, mixed flotation is performed using oleic acid as a collector to obtain mixed concentrate of fluorite and barite.

The mixed concentrate is then separated via direct flotation or reverse flotation to produce high-purity fluorite concentrate.

Separation of Fluorite and Quartz:

Fatty acids are used as collectors to target fluorite, while sodium silicate acts as an inhibitor for quartz.

Sodium silicate dosage is strictly controlled: a small amount activates fluorite but insufficiently inhibits quartz, while excess dosage suppresses fluorite.

Multivalent metal ions may be added to enhance sodium silicate’s inhibitory effect on quartz (with secondary inhibition of calcite).

Separation of Fluorite and Sulfide Ore:

For fluorite ore containing sulfide minerals, xanthate collectors are first used to float sulfide ore away.

Fatty acid collectors are then added to flotation fluorite.

A small amount of sulfide mineral inhibitor can be incorporated to suppress residual sulfide ore, ensuring fluorite concentrate quality.

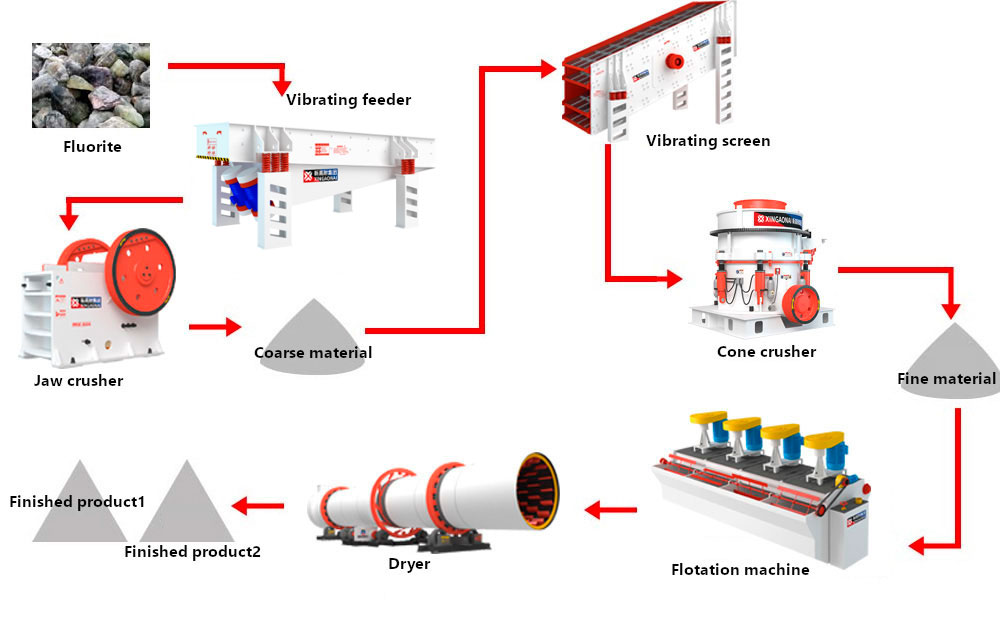

Key Equipment Configuration for Fluorite Beneficiation Line

Our fluorite processing solution integrates high-efficiency equipment tailored to flotation and crushing needs:

Feeding & Crushing Equipment: Vibrating feeder (uniform feeding), jaw crusher (coarse crushing), cone crusher (fine crushing)

Separation Equipment: Flotation machine (core separation tool for mineral separation)

Drying Equipment: Dryer (dries final concentrate for storage and transportation)

Auxiliary Equipment: Slurry mixer (prepares flotation slurry), reagent dosing system (controls collector/inhibitor dosage)

Screening Equipment: Vibrating screen (grades crushed ore to ensure flotation efficiency)

Core Advantages of Our Fluorite Beneficiation Process

Targeting fluorite’s mineral association and industrial quality requirements, our solution offers distinct competitive edges:

Precise Mineral Separation: Tailored flotation formulas and process parameters ensure effective separation of fluorite from barite, quartz, and sulfide ore—concentrate grade reaches industrial high standards.

Controlled Reagent Dosage: Scientific regulation of collectors (oleic acid, xanthate) and inhibitors (sodium silicate) avoids waste and ensures stable flotation effects.

High Concentrate Recovery: Optimized flotation workflow and equipment combination improve fluorite recovery rate by 15-20% compared to traditional processes.

Eco-Friendly Operation: Low-toxicity reagents and closed-loop slurry system minimize environmental impact, complying with global industrial emission regulations (CE, EPA).

Customizable Design: Adapts to different ore properties (e.g., varying proportions of associated minerals) and production capacity (50-1000 TPH).

Application Scenarios of Fluorite Processing Solution

Our fluorite beneficiation process is widely applied in global industrial raw material production:

Steelmaking Industry: Provides high-purity fluorite as a flux to remove impurities (phosphorus, sulfur) and improve steel quality.

Glass & Enamel Production: Supplies fluorite concentrate to enhance glass transparency and enamel adhesion.

Optical Industry: Delivers high-grade fluorite for synthetic crystals, used in manufacturing low-dispersion camera lenses and optical components.

Chemical Industry: Serves as a raw material for extracting fluorine and producing fluoride chemicals.

Customized Fluorite Beneficiation Solution for Your Project

We recognize that fluorite ore properties (associated mineral types, content ratio, particle size) vary by mine. Instead of one-size-fits-all solutions, we offer tailored services:

Conduct on-site ore testing and investigation to analyze fluorite characteristics and associated mineral composition.

Design optimized flotation process flows and equipment combinations based on your concentrate grade requirements and production capacity.

Provide full-life-cycle services: equipment manufacturing, on-site installation, commissioning, operator training, and technical guidance.

Offer long-term after-sales support and genuine spare parts supply to ensure continuous, stable operation of the beneficiation line.

Conclusion

Fluorite’s versatility makes it irreplaceable in steel, glass, optical, and chemical industries, and a professional fluorite beneficiation process is the key to maximizing its industrial value. Our custom solution, focusing on precise flotation separation of associated minerals, delivers high-grade concentrate, efficient recovery, and eco-friendly operation.

Whether you operate a fluorite mine, mineral processing plant, or industrial raw material supplier, we can deliver a tailored fluorite processing solution to align with your goals. Partner with us to build a high-efficiency, cost-effective fluorite beneficiation line and gain a competitive edge in the global industrial raw materials market.