Feldspar is the most abundant rock-forming mineral on the earth’s surface, a group of aluminum silicate minerals containing calcium, sodium, and potassium. It is a critical raw material for the ceramic, glass, and enamel industries, and can also be used to extract rare elements like rubidium and cesium, or as decorative stones. To meet industrial quality requirements, a professional feldspar processing solution is essential—integrating crushing, screening, grinding, desliming, and sorting technologies to remove impurities and improve feldspar purity. Our custom feldspar beneficiation process is tailored to the mineral properties of feldspar, ensuring high-purity finished products for diverse industrial applications.

Core Process of Feldspar Processing Solution

The feldspar processing solution follows a scientific multi-stage process to achieve efficient purification and grading:

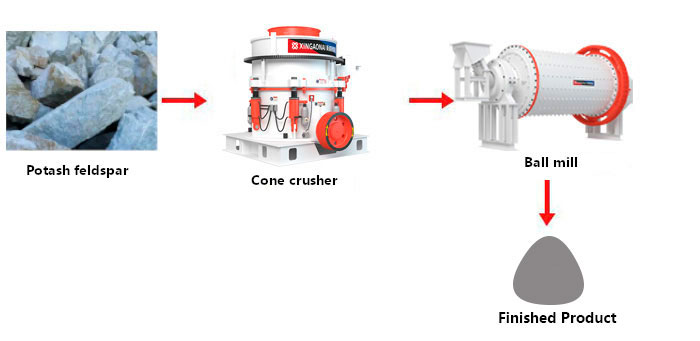

Crushing & Screening: Based on raw ore particle size, the process ranges from single-stage to three-stage crushing. Block feldspar is coarsely crushed, then screened—qualified ore enters the grinding stage, while oversize ore is returned to fine crushing (e.g., cone crusher) to ensure proper particle size for subsequent processing.

Grinding & Classification: Qualified crushed ore is fed into a ball mill for grinding. The mill discharge is sent to classification equipment; settled sand returns to the ball mill for re-grinding, and overflow becomes the qualified product of the grinding stage.

Desliming: Ground qualified material is transferred to a desliming bucket to remove sludge and fine impurities, laying the foundation for efficient sorting.

Sorting:

Key Equipment Configuration for Feldspar Beneficiation Line

Our feldspar processing solution is equipped with specialized, high-efficiency equipment to match feldspar’s processing needs:

Crushing Equipment: Jaw crusher (coarse crushing), cone crusher (fine crushing)

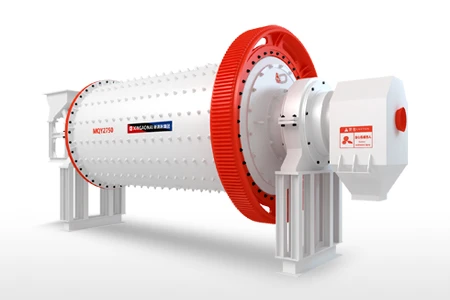

Grinding Equipment: Ball mill (precision grinding of feldspar ore)

Classification Equipment: Hydrocyclone (grinding product grading)

Desliming Equipment: Desliming bucket (sludge removal)

Sorting Equipment: Weak/strong magnetic separators (magnetic impurity removal), flotation machine (impurity purification)

Auxiliary Equipment: Vibrating feeder (uniform feeding), vibrating screen (crushing product screening), dust removal system (environmental compliance)

Core Advantages of Our Feldspar Processing Solution

Targeting feldspar’s purification requirements and industrial application needs, our feldspar processing solution offers distinct competitive edges:

High Purity Output: Multi-stage sorting (magnetic separation + flotation) reduces impurity content, delivering feldspar concentrate with purity meeting ceramic, glass, and enamel industry standards.

Tailored Process Design: Adapts to different feldspar types (e.g., potash feldspar) and raw ore properties, optimizing crushing/grinding intensity and sorting parameters for optimal results.

Efficient Operation: Optimized equipment combination shortens processing flow, reduces energy consumption per ton by 15-20%, and improves production efficiency.

Stable Performance: Wear-resistant components (mill liners, crusher jaws) and intelligent monitoring systems ensure continuous operation, reducing downtime and maintenance costs.

Eco-Friendly Compliance: Closed-loop processing and dust removal equipment minimize environmental impact, meeting global industrial emission regulations (CE, EPA).

Application Scenarios of Feldspar Processing Solution

Our feldspar beneficiation line is widely applied in global industrial raw material production projects:

Ceramic Industry: Provides high-purity feldspar as flux and refractory material for ceramic bodies and glazes, enhancing product whiteness and sintering performance.

Glass Industry: Supplies feldspar for flat glass, container glass, and specialty glass production—enhancing glass transparency and mechanical strength.

Enamel Industry: Delivers refined feldspar as a raw material for enamel coatings, ensuring coating adhesion and corrosion resistance.

Rare Element Extraction: Processes feldspar containing rubidium, cesium, and other rare elements, enabling efficient extraction of valuable minerals.

Decorative Stone Production: Processes color-rich feldspar into decorative stones and semi-precious gems for architectural and ornamental use.

Customized Feldspar Processing Solution for Your Project

We recognize that feldspar ore properties (composition, impurity content, particle size) and industrial application requirements vary widely. Instead of one-size-fits-all solutions, we offer tailored feldspar processing solution:

Conduct on-site ore testing and investigation to analyze feldspar type, impurity composition, and site conditions.

Design optimized process flows and equipment combinations based on your production capacity, concentrate purity requirements, and budget.

Provide full-life-cycle services: equipment manufacturing, on-site installation, commissioning, operator training, and technical guidance.

Offer long-term after-sales support and genuine spare parts supply to ensure continuous, stable operation of the processing line.

Conclusion

Feldspar’s versatility and abundance make it a cornerstone raw material for multiple industries, and a professional feldspar processing solution is the key to unlocking its industrial value. Our custom beneficiation line, integrating crushing, grinding, desliming, and multi-stage sorting, delivers high-purity feldspar concentrate that meets strict industrial standards.

Whether you operate a feldspar mine, a mineral processing plant, or an industrial raw material supplier, we can deliver a tailored feldspar processing solution to align with your goals. Partner with us to build a high-efficiency, cost-effective feldspar beneficiation line and gain a competitive edge in the global industrial raw materials market.