What Is a Vibrating Feeder: Core Definition

Working Principle of a Vibrating Feeder

1. Electromagnetic Drive (Small-to-Medium Capacity)

An electromagnetic coil generates alternating current, creating rapid magnetic attraction and repulsion.

This vibration is transmitted to the feeder’s trough (the material-carrying surface), causing it to vibrate at high frequency (3000-6000 vibrations per minute).

Materials on the trough move forward in small, continuous jumps, guided by the trough’s inclined angle (usually 5-15°).

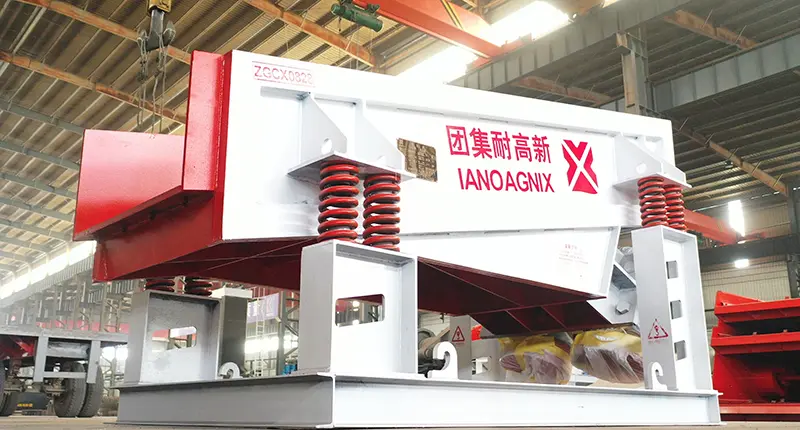

2. Motor-Driven Drive (Large-Capacity, Heavy-Duty)

Equipped with two eccentric motors rotating in opposite directions, creating linear or circular vibration.

The motors’ synchronized rotation generates a resultant force that moves the trough back and forth or in a circular motion.

This vibration propels materials forward with greater force, making it suitable for heavy, abrasive materials (e.g., granite, iron ore).

Key Features of a High-Quality Vibrating Feeder

Uniform Feeding: Vibration ensures materials move at a steady, consistent rate, preventing uneven loading on crushers or screens.

Precise Control: Adjustable feed rate (from 1-1000 t/h) adapts to different production demands, from small-scale processing to large mining operations.

Durable Construction: Troughs made of wear-resistant steel or polyurethane withstand abrasive materials, extending service life.

Compact Design: Takes up minimal space in production lines, easy to integrate with existing equipment.

Low Energy Consumption: Efficient vibration technology reduces power usage compared to traditional conveyors.

Easy Maintenance: Few moving parts (especially electromagnetic models) minimize downtime and repair costs.

Dust & Noise Reduction: Sealed trough options and vibration damping systems meet environmental standards.

Main Types of Vibrating Feeders

1. Electromagnetic Vibrating Feeder

Best For: Fine powders, small granules (e.g., coal dust, cement, grain), and low-to-medium capacity lines.

Pros: Quiet operation, precise feed control, low maintenance.

Cons: Not suitable for heavy or abrasive materials.

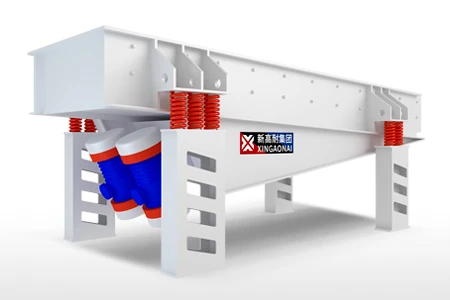

2. Motor-Driven Vibrating Feeder (Linear/Circular)

Best For: Heavy-duty applications, abrasive materials (e.g., ore, crushed stone), and high-capacity production.

Linear Type: Materials move in a straight line, ideal for feeding crushers and screens.

Circular Type: Materials move in a spiral, suitable for hopper discharge and uniform spreading.

3. Vibrating Tube Feeder

Best For: Powdery or toxic materials (sealed design prevents dust leakage).

Design: Cylindrical tube replaces the trough, ideal for chemical or pharmaceutical industries.

Industrial Applications of Vibrating Feeders

Mining Industry: Feeding ore (iron ore, copper ore, gold ore) into crushers, grinders, or beneficiation equipment.

Aggregate Production: Conveying crushed stone, gravel, or sand to screens or concrete mixing plants.

Manufacturing: Feeding raw materials (e.g., plastics, ceramics, metal powders) into production lines.

Coal Industry: Transporting coal from silos to boilers or coal crushers.

Chemical Industry: Handling powdery chemicals (e.g., fertilizer, limestone powder) with sealed troughs.

Recycling: Sorting and feeding construction waste (concrete, bricks) into crushing and recycling equipment.

How to Choose the Right Vibrating Feeder

Material Properties: Hardness, particle size, moisture content (e.g., wet materials may require anti-clogging designs).

Production Capacity: Match the feeder’s output to your line’s needs (small electromagnetic models for low capacity, motor-driven for high volume).

Application Environment: Indoor/outdoor use, temperature, and dust requirements (sealed models for harsh conditions).

Downstream Equipment: Ensure compatibility with crushers, screens, or mixers (e.g., linear feeders for crushers, circular for screens).