Graphite is a naturally occurring crystalline mineral composed of carbon, valued for its exceptional conductivity, thermal stability, lubricity, and chemical inertness. It is widely used in lithium-ion batteries (anode material), metallurgical fluxes, electrical components, refractory materials, and advanced composites. To meet industrial quality standards (especially high-purity requirements for battery and electronic applications), a specialized graphite ore beneficiation process is essential—focused on separating graphite from associated minerals (quartz, mica, feldspar, pyrite) and upgrading its carbon content. Our custom graphite processing solution is tailored to different graphite ore types (flake graphite, amorphous graphite) and ore properties, delivering high-purity graphite concentrate that unlocks maximum industrial value.

Core Beneficiation Processes of Graphite Ore Processing Solution

Graphite ore processing varies by ore type and associated mineral composition, with flotation as the core separation technology. Below are the key processes for mainstream graphite ore types:

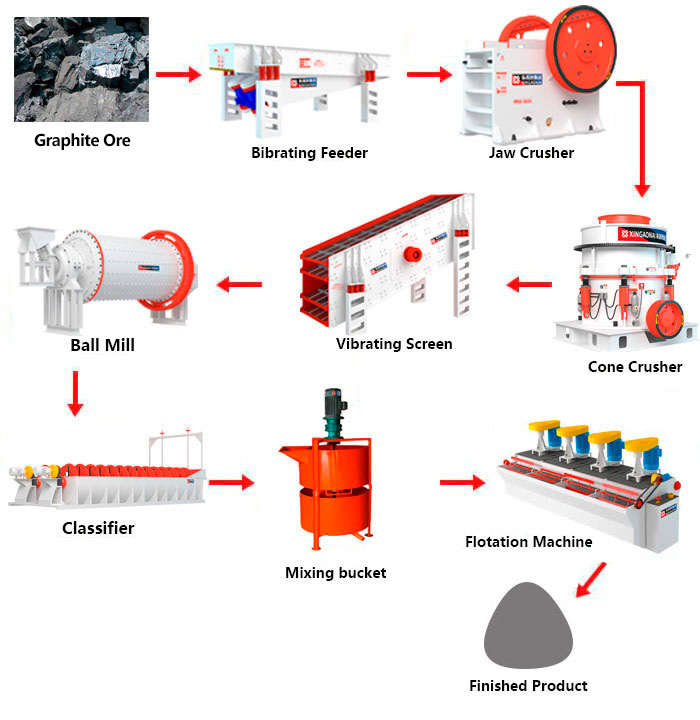

1. Beneficiation Process for Flake Graphite Ore

Flake graphite is characterized by its scaly crystal structure (size 1–20mm), and preserving flake integrity is critical to its value. The process focuses on gentle separation:

Crushing & Grinding: Raw ore is coarsely crushed via jaw crusher, then finely ground in a ball mill or rod mill. The grinding process is controlled to avoid flake breakage—oversized particles are recycled for re-grinding, while qualified slurry (with exposed graphite flakes) enters flotation.

Flotation Separation: Graphite is naturally hydrophobic, so a flotation process with low-cost collectors (e.g., diesel oil, kerosene) and foaming agents (e.g., pine oil) is used. Associated minerals (quartz, feldspar) are hydrophilic and remain in the tailings, while graphite adheres to air bubbles to form concentrate.

Multi-Stage Cleaning: Primary flotation concentrate undergoes 3–5 stages of cleaning flotation to remove residual impurities, upgrading carbon content to 85–95%.

Drying & Screening: Cleaned concentrate is dried in a rotary dryer and screened to classify flake sizes (critical for battery-grade applications).

2. Beneficiation Process for Amorphous Graphite Ore

Amorphous graphite (microcrystalline graphite) has fine crystal particles and high natural carbon content (60–80%). The process prioritizes efficient impurity removal:

Crushing & Grinding: Raw ore is crushed and ground to fine powder (200–325 mesh) to liberate graphite from gangue minerals.

Flotation or Gravity Separation: For low-impurity ore, gravity separation (spirals, shaking tables) is used to enrich graphite; for high-impurity ore, flotation (similar to flake graphite) is adopted to improve purity.

Purification (Optional): For high-grade applications (e.g., battery materials), chemical purification (acid leaching) or thermal purification (high-temperature calcination) is added to raise carbon content to 99.9%+ (battery-grade standard).

3. Separation of Graphite from Key Associated Minerals

Graphite often coexists with quartz, mica, and pyrite—targeted separation steps ensure concentrate quality:

Graphite & Quartz/Mica Separation: Sodium silicate is added as an inhibitor to suppress quartz and mica during flotation, enhancing graphite selectivity.

Graphite & Pyrite Separation: Xanthate collectors are used to pre-flotation pyrite (a sulfide mineral) before graphite flotation, avoiding pyrite contamination.

Key Equipment Configuration for Graphite Beneficiation Line

Our graphite processing solution integrates specialized, high-efficiency equipment tailored to ore characteristics and process requirements:

Feeding & Crushing Equipment: Vibrating feeder (uniform feeding), jaw crusher (coarse crushing), cone crusher (fine crushing)

Grinding Equipment: Ball mill/rod mill (gentle grinding for flake graphite), Raymond mill (for amorphous graphite)

Separation Equipment: Flotation machine (core flotation tool), gravity separator (spirals/shaking tables for amorphous graphite)

Purification Equipment: Acid leaching tank (chemical purification), high-temperature furnace (thermal purification)

Drying & Screening Equipment: Rotary dryer (concentrate drying), high-frequency vibrating screen (flake classification)

Auxiliary Equipment: Reagent dosing system (precise control of collectors/inhibitors), slurry mixer (flotation preparation), dust removal system (environmental compliance)

Core Advantages of Our Graphite Ore Beneficiation Process

Targeting graphite’s mineral characteristics and industrial quality demands, our solution offers distinct competitive edges:

Ore-Type Adaptability: Custom processes for flake and amorphous graphite, optimizing grinding intensity and flotation parameters to maximize recovery and preserve flake value.

High Purity & Recovery: Multi-stage flotation + optional purification delivers concentrate with carbon content 85–99.9%+ (meets metallurgical, electronic, and battery-grade standards); graphite recovery rate reaches 85–92%, higher than traditional processes.

Flake Integrity Preservation: Gentle grinding and low-turbulence flotation minimize flake breakage, maintaining the high value of large-flake graphite.

Eco-Friendly Operation: Low-toxicity flotation reagents, closed-loop slurry systems, and dust removal equipment comply with global environmental regulations (CE, EPA); acid leaching wastewater is treated for recycling.

Cost-Efficient Design: Optimized equipment combination and reagent dosing reduce energy consumption by 12–18% and reagent costs by 10–15% compared to standard lines.

Application Scenarios of Graphite Processing Solution

Our graphite beneficiation line is widely applied in global industrial raw material production:

Battery Industry: Produces battery-grade graphite (99.9%+ carbon content) for lithium-ion battery anodes—used in electric vehicles, consumer electronics, and energy storage systems.

Metallurgical Industry: Supplies graphite concentrate as a flux in steelmaking and casting, reducing melting temperature and removing impurities (sulfur, phosphorus).

Electronics Industry: Delivers high-purity graphite for electrical contacts, electrodes, and thermal management components—leveraging its conductivity and thermal stability.

Refractory & Lubricant Industry: Provides graphite for refractory bricks (high-temperature resistance) and lubricants (excellent lubricity in harsh environments).

Advanced Materials: Processes graphite for carbon fiber composites, graphene production, and nuclear reactor components.

Customized Graphite Ore Beneficiation Solution for Your Project

We recognize that graphite ore properties (ore type, flake size, associated mineral content) and project requirements vary widely. Instead of one-size-fits-all solutions, we offer tailored services:

Conduct on-site ore testing and investigation to analyze graphite type, flake size distribution, and associated mineral composition.

Design optimized process flows and equipment combinations based on your production capacity (50–1000 TPH) and target concentrate grade (metallurgical/battery/electronic grade).

Provide full-life-cycle services: equipment manufacturing, on-site installation, commissioning, operator training, and technical guidance.

Offer long-term after-sales support and genuine spare parts supply to ensure continuous, stable operation of the beneficiation line.

Conclusion

Graphite’s unique physical and chemical properties make it a critical raw material for emerging industries (EV batteries, renewable energy storage) and traditional sectors (metallurgy, refractories). A professional graphite ore beneficiation process is the key to unlocking its full value, delivering high-purity, high-recovery concentrate that meets strict industrial standards.

Whether you operate a flake graphite mine, amorphous graphite quarry, or mineral processing plant, we can deliver a tailored graphite processing solution to align with your goals. Partner with us to build a high-efficiency, cost-effective graphite beneficiation line and gain a competitive edge in the global graphite raw materials market.