River pebbles are silicate minerals renowned for their hard texture, wear resistance, and stable chemical properties. As an abundant and cost-effective raw material, they are processed into river pebble sand and aggregates—critical for hydropower projects, high-grade highways, railways, bridges, airport runways, municipal engineering, and high-rise building construction. River pebble sand also serves as a premium aggregate for concrete, offering excellent performance and economic value. To maximize the potential of this material, a specialized river pebbles crushing solution is essential—tailored to handle its wear resistance while delivering uniform, high-quality finished products. Our custom river pebble processing line integrates multi-stage crushing, shaping, screening, and cleaning technologies to meet diverse industrial demands.

Core Process of River Pebbles Crushing Solution

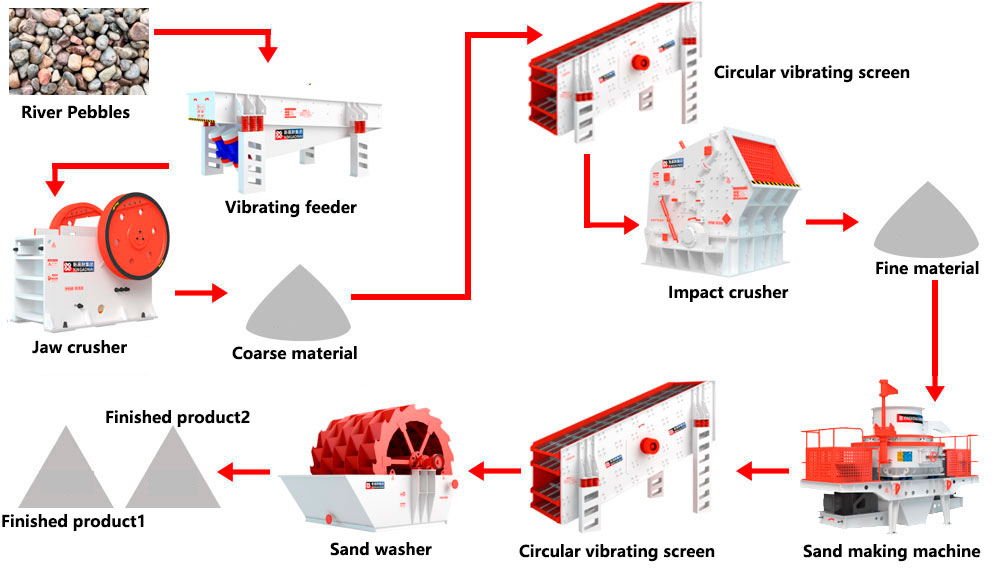

The river pebbles crushing solution follows a scientific three-stage process to ensure efficient processing and optimal product quality:

Coarse Crushing: Large river pebbles are evenly fed via a vibrating feeder from the silo to a jaw crusher. This step reduces raw river pebbles (up to 1000mm) into coarse particles, providing a stable feed for subsequent processing.

Medium & Fine Crushing: Coarsely crushed river pebbles are screened by a vibrating screen, then transported via belt conveyor to an impact crusher or cone crusher for medium and fine crushing. Oversized particles are recycled back to the crusher for reprocessing, ensuring consistent particle size.

Shaping & Cleaning: The crushed river pebbles are sent to a sand making machine for further crushing and cubical shaping—enhancing aggregate roundness and reducing flakiness. If clean river pebble products are required, the material is transferred to a sand washing machine to remove dust, mud, and impurities, meeting strict construction material standards.

Key Equipment Configuration for River Pebble Processing Line

Our river pebbles crushing solution is equipped with wear-resistant, high-efficiency equipment specifically adapted to river pebbles’ properties:

Feeding Equipment: Vibrating feeder (ensures uniform feeding, prevents crusher overload)

Crushing Equipment: Jaw crusher (coarse crushing), impact crusher/cone crusher (medium & fine crushing)

Shaping Equipment: Sand making machine (optimizes particle shape, produces cubical sand/aggregate)

Screening Equipment: Circular vibrating screen (precise grading, ensures product uniformity)

Cleaning Equipment: Sand washing machine (removes impurities, delivers clean finished products)

Conveying Equipment: Wear-resistant belt conveyor (connects processes, ensures continuous operation)

Auxiliary Equipment: Dust removal system (controls emissions, meets environmental regulations)

Core Advantages of Our River Pebbles Crushing Solution

Targeting river pebbles’ wear resistance and processing needs, our river pebbles crushing solution offers distinct competitive edges:

Exceptional Wear Resistance: Critical components (crusher liners, sand making machine rotors) are made of high-chromium alloy or manganese steel, extending service life by 25-35% compared to standard equipment.

High-Quality Finished Products: Multi-stage crushing + shaping process produces cubical sand/aggregate with flakiness rate ≤10% and uniform gradation—ideal for concrete and high-grade construction projects.

Efficient & Cost-Effective: Optimized process flow reduces energy consumption per ton by 12-18%, while river pebbles’ abundant supply and low collection cost lower overall production expenses.

Customizable Design: The line adapts to production capacity (50-1800 TPH) and finished product requirements (0-5mm sand, 5-20mm aggregate, 20-40mm road base).

Eco-Friendly Operation: Closed-loop processing + dust removal equipment minimizes dust and noise, complying with global environmental standards (CE, EPA).

Stable & Easy Maintenance: Simplified equipment structure and intelligent monitoring systems enable real-time operation tracking, reducing downtime and maintenance costs.

Application Scenarios of River Pebbles Crushing Solution

Our river pebble processing line is widely applied in global construction, infrastructure, and engineering projects:

Highway & Railway Construction: Produces high-strength aggregate for road bases, asphalt pavements, and railway ballast—enhancing durability and load-bearing capacity.

Concrete Production: Supplies premium river pebble sand/aggregate for ready-mix concrete, precast components, and high-rise building foundations.

Hydraulic & Municipal Engineering: Provides durable materials for dams, bridges, airport runways, and municipal road construction—resisting water erosion and wear.

Quarry Mining: Enables large-scale, automated river pebble extraction and processing, maximizing quarry economic benefits.

Building Decoration: Processes river pebbles into decorative aggregates for landscape projects, building facades, and garden design.

Customized River Pebbles Crushing Solution for Your Project

We recognize that river pebble properties (hardness, particle size, impurity content) and project requirements vary widely. Instead of one-size-fits-all solutions, we offer tailored river pebbles crushing solution:

Conduct on-site investigations and ore testing to analyze river pebble characteristics and site conditions.

Design optimized equipment combinations and process flows based on your production capacity, finished product standards, and budget.

Provide full-life-cycle services: equipment manufacturing, on-site installation, commissioning, operator training, and technical guidance.

Offer long-term after-sales support and genuine spare parts supply to ensure continuous, stable operation of the processing line.

Conclusion

River pebbles’ durability, abundance, and cost-effectiveness make them an irreplaceable raw material in construction and infrastructure industries. A professional river pebbles crushing solution is the key to unlocking their full value, delivering high-quality sand and aggregates that meet the strictest project standards.

Whether you operate a small river pebble quarry, a large aggregate production plant, or an infrastructure construction company, we can deliver a tailored river pebbles crushing solution to align with your goals. Partner with us to build a high-efficiency, cost-effective river pebble processing line and gain a competitive edge in the global construction materials market.