Barite is a non-metallic mineral primarily composed of barium sulfate, often coexisting with sulfide ores (galena, sphalerite, chalcopyrite) and iron-bearing minerals. As a non-renewable resource, it is widely used as a weighting agent in oil/gas drilling mud, raw material for barium chemicals and fillers, and a contrast agent in medical digestive system examinations. To meet industrial quality standards (e.g., low iron content for medical use, high purity for drilling), a specialized barite beneficiation process is essential—integrating crushing, screening, gravity separation, magnetic separation, and flotation to separate impurities and upgrade grade. Our custom barite processing solution is tailored to ore properties, delivering high-grade concentrate that maximizes industrial value.

Core Beneficiation Processes of Barite Processing Solution

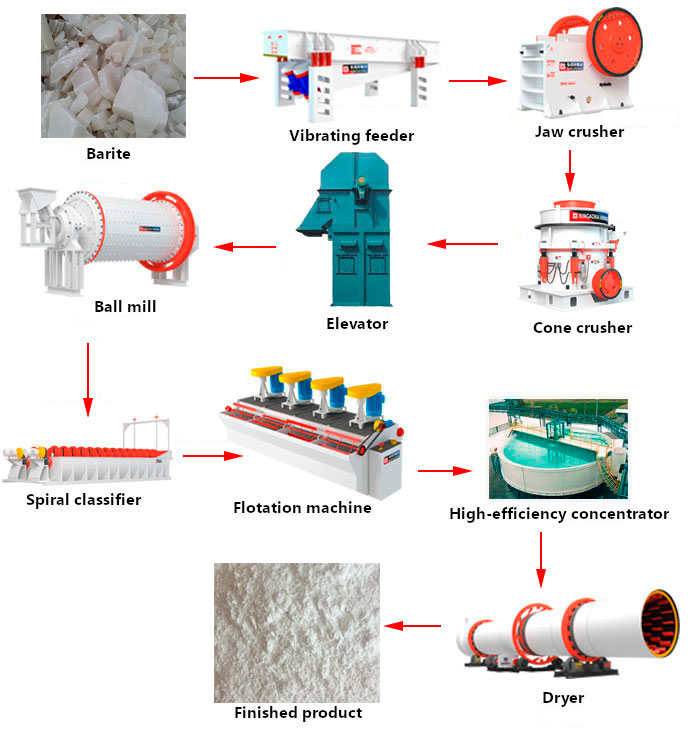

Barite ore requires targeted separation based on particle size and impurity type, with four key process stages:

Crushing & Screening:

Large mined barite is crushed by a jaw crusher (coarse crushing) and cone crusher (fine crushing) to suitable particle size.

A circular vibrating screen (high capacity, low failure rate) sorts crushed materials, ensuring qualified particles enter subsequent separation stages.

Gravity Separation (Jigging):

Jigging machines are the core equipment for barite gravity separation, handling both coarse and fine particles.

This process yields high-grade concentrate (purity ≥80%) with advantages of energy saving, high efficiency, and environmental friendliness.

It is the primary method for upgrading barite, leveraging density differences between barite and gangue minerals.

Magnetic Separation (Iron Removal):

Wet magnetic separators are used to remove iron-bearing minerals (e.g., siderite) from barite.

Critical for producing medical-grade barite (required for barium-based medicines with ultra-low iron content).

Flotation Separation:

Applied to finely disseminated barite ore and gravity separation tailings, where physical separation is ineffective.

Anionic collectors (fatty acid alkyl sulfates, alkyl sulfonates) or cationic amine collectors are selected based on adsorption mechanisms to float barite.

Key Equipment Configuration for Barite Beneficiation Line

Our barite processing solution integrates high-efficiency equipment tailored to process requirements:

Feeding & Crushing Equipment: Vibrating feeder (uniform feeding), jaw crusher (coarse crushing), cone crusher (fine crushing)

Grinding Equipment: Ball mill (liberates barite from gangue), spiral classifier (grinding product grading)

Separation Equipment: Jigging machine (gravity separation), wet magnetic separator (iron removal), flotation machine (fine ore separation)

Concentration & Drying Equipment: High-efficiency concentrator (slurry concentration), dryer (finished concentrate drying)

Auxiliary Equipment: Elevator (material transportation), reagent dosing system (collector/inhibitor control), dust removal system (environmental compliance)

Core Advantages of Our Barite Beneficiation Process

Targeting barite’s mineral characteristics and industrial quality demands, our solution offers distinct competitive edges:

Multi-Process Adaptability: Combines gravity, magnetic, and flotation separation to handle different ore types (coarse/fine particles, high/low impurity content).

High Purity & Yield: Gravity separation delivers ≥80% concentrate grade; flotation upgrades fine ore to meet strict industrial standards; overall recovery rate reaches 85-90%.

Precise Iron Removal: Wet magnetic separation reduces iron content to meet medical and high-end industrial requirements.

Cost-Efficient Operation: Gravity separation minimizes reagent usage; optimized equipment combination reduces energy consumption by 12-18% compared to traditional lines.

Environmental Compliance: Closed-loop slurry systems, low-toxicity flotation reagents, and dust removal equipment meet global regulations (CE, EPA).

Application Scenarios of Barite Processing Solution

Our barite beneficiation line serves diverse global industrial sectors:

Oil & Gas Drilling: Produces high-density barite concentrate (weighting agent) for drilling mud, stabilizing wellbores under high pressure.

Chemical Industry: Supplies high-purity barite for barium chemical production (barium carbonate, barium chloride).

Fillers & Coatings: Delivers fine barite powder as a filler in plastics, rubber, and coatings, enhancing product hardness and wear resistance.

Medical Industry: Produces ultra-low iron barite as a contrast agent for digestive system imaging.

Construction Materials: Processes barite into aggregate for radiation-shielding concrete in hospitals and nuclear facilities.

Customized Barite Beneficiation Solution for Your Project

We recognize that barite ore properties (particle size, associated mineral content, impurity type) vary by mine. Instead of one-size-fits-all solutions, we offer tailored services:

Conduct on-site ore testing and investigation to analyze barite purity, associated mineral composition, and particle size distribution.

Design optimized process flows and equipment combinations based on your production capacity (50-1200 TPH) and target concentrate grade (industrial/medical/drilling grade).

Provide full-life-cycle services: equipment manufacturing, on-site installation, commissioning, operator training, and technical guidance.

Offer long-term after-sales support and genuine spare parts supply to ensure continuous, stable operation of the beneficiation line.

Conclusion

Barite’s unique density and chemical inertness make it irreplaceable in oil drilling, chemicals, medical, and construction industries. A professional barite beneficiation process is the key to unlocking its full value, delivering high-purity, high-yield concentrate that meets strict industrial standards.

Whether you operate a barite mine, mineral processing plant, or industrial raw material supplier, we can deliver a tailored barite processing solution to align with your goals. Partner with us to build a high-efficiency, cost-effective barite beneficiation line and gain a competitive edge in the global barite raw materials market.