A cone crusher is a complex piece of machinery critical for reducing large rocks into smaller aggregates, gravel, or sand. Its reliable operation hinges on the seamless interaction of its core cone crusher components. Understanding these parts—their functions, importance, and maintenance needs—is key to maximizing productivity, minimizing downtime, and ensuring the longevity of your equipment. As a leading manufacturer, XGN Heavy Industry designs its XHP Series Multi-Cylinder Hydraulic Cone Crushers with robust, high-performance components for unparalleled durability.

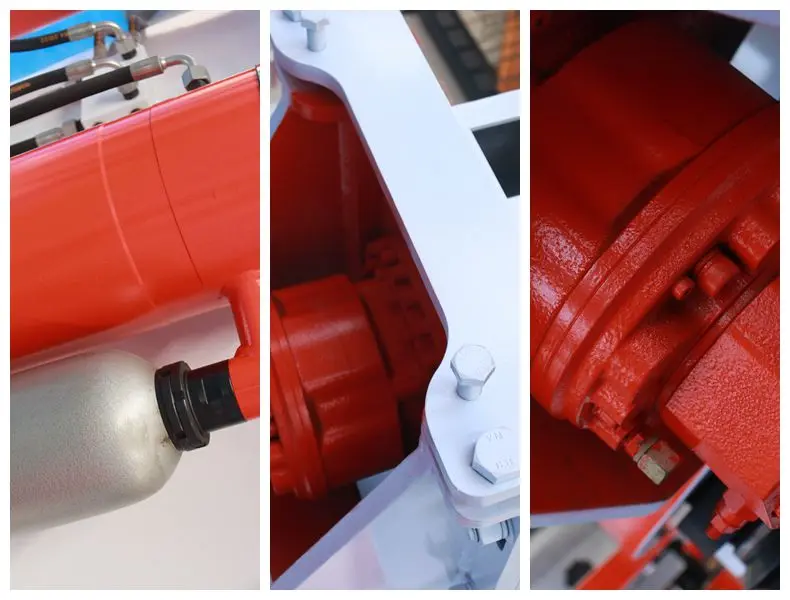

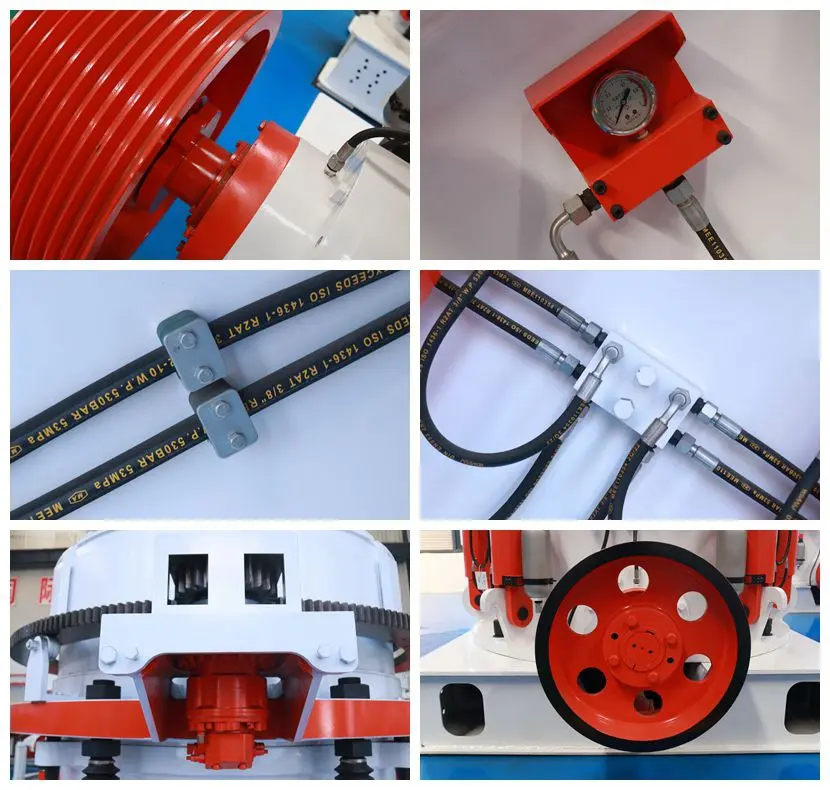

Mantle and Concave (Wear Parts): Function: These are the primary cone crusher components responsible for the actual crushing. The mantle is the moving wear surface that gyrates within the concave, which is the fixed wear surface. The rock is crushed between these two surfaces. Importance: Made from high manganese or other advanced alloys, their quality directly impacts crushing efficiency, product shape, and wear life. XGN uses premium materials to ensure these parts withstand extreme abrasion and impact. Main Shaft and Eccentric Assembly (The Driving Force): Function: The main shaft is the central component that the mantle is attached to. This assembly is driven by a gear and rotates within an eccentric bushing. This unique motion creates the gyrating action that crushes the rock against the concave. Importance: The precision engineering of the shaft and eccentric assembly is crucial for smooth, stable operation and consistent performance. It's the heart of the crusher's mechanical action. Hydraulic System (Control and Protection): Adjusting the CSS (Closed Side Setting): Allows for precise control over the crusher's output product size. Clearing the Cavity: Safely relieves the crushing chamber in the event of an uncrushable material (like tramp iron) entering, protecting the machine from severe damage. Providing Clamping Force: The hydraulic cylinders ensure a stable crushing force. Function: In modern multi-cylinder hydraulic cone crushers like the XHP Series, the hydraulic system is a critical set of cone crusher components. It performs several vital tasks: Importance: This system is central to automation, safety, and operational flexibility, reducing manual intervention and preventing costly downtime. Bowl and Adjustment Ring: Function: The concave liners are seated in the adjustment ring (or bowl). By rotating this ring, the vertical position of the concave can be adjusted, which is part of setting the crusher's discharge opening. Importance: This robust structure must withstand tremendous pressure. Its integrity is essential for maintaining precise crushing geometry. Countershaft and Pinion Gear: Function: This assembly transfers power from the motor to the eccentric bushing, initiating the gyrating motion of the main shaft. Importance: High-strength gears are essential for reliable power transmission under heavy loads.

Why the Quality of These Components Matters

Frequent Failures: Increased unplanned downtime for repairs. Higher Operating Costs: Constant replacement of worn-out parts. Inconsistent Output: Poor product shape and unpredictable gradation. Reduced Efficiency: Higher energy consumption for lower throughput.

Premium Materials: We use high-grade steels and alloys to combat wear and fatigue. Precision Manufacturing: Every component is machined to exact tolerances for perfect fit and long-term reliability. Rigorous Testing: Parts undergo strict quality checks to ensure they meet our high standards. Expert Support: Our service team provides guidance on maintenance and offers genuine replacement parts to keep your crusher operating at peak performance.