What Is a Sand Washing Machine: Core Definition

Working Principle of a Sand Washing Machine

Feeding Stage: Raw sand (natural sand or crushed artificial sand) is fed into the sand washing machine through a feeder or conveyor belt. The feed rate is controlled to ensure optimal cleaning efficiency, avoiding overloading the equipment.

Cleaning Stage: Inside the machine, sand particles are subjected to two key forces: water flushing and mechanical agitation. Water is sprayed into the washing chamber to dissolve and wash away soluble impurities (e.g., clay, silt). Meanwhile, rotating impellers, spirals, or wheels agitate the sand, breaking up clumps and separating adhered impurities from the sand surface.

Separation Stage: Impurities (lighter than sand particles) are carried away by the water flow and discharged as wastewater (which can be recycled via a sedimentation tank for environmental protection). Clean sand particles, heavier in weight, are retained and moved to the dewatering or grading section.

Dewatering & Discharge Stage: Clean sand is dewatered to reduce moisture content (typically to 8-12%) and then discharged from the machine. Some advanced sand washing machines also include grading functions to separate sand into different particle sizes, meeting specific project requirements.

Key Features of a High-Quality Sand Washing Machine

High Cleaning Efficiency: Effectively removes 95%+ of impurities, ensuring the finished sand meets national construction standards for cleanliness and gradation.

Low Sand Loss Rate: Advanced structural design minimizes the loss of fine sand (particle size < 0.16mm), reducing material waste and improving production yield.

Durable Construction: Washing chambers, impellers, and liners are made of wear-resistant materials (e.g., high-manganese steel, polyurethane), extending service life in harsh working environments.

Energy & Water Saving: Optimized water circulation systems reduce water consumption by 30-50% compared to traditional models; energy-efficient motors lower operational costs.

Easy Operation & Maintenance: Simple control panel, detachable components, and low failure rate ensure convenient operation and minimal downtime for maintenance.

Environmental Compliance: Equipped with wastewater recycling accessories to reduce environmental impact, complying with modern industrial pollution control standards.

Main Types of Sand Washing Machines

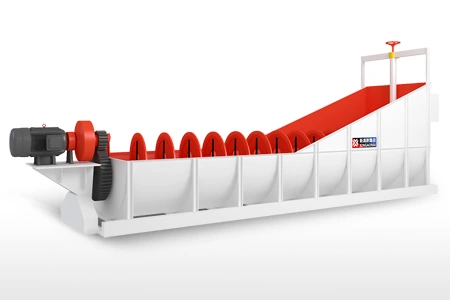

1. Spiral Sand Washing Machine

2. Wheel Sand Washing Machine

3. Bucket Sand Washing Machine

Industrial Applications of Sand Washing Machines

Construction Industry: Cleaning sand for concrete, mortar, and dry-mixed mortar, ensuring the strength and durability of buildings, bridges, and highways.

Aggregate Production: Processing artificial sand (crushed from stone) to remove powder and impurities, improving product quality for construction projects.

Mining Industry: Cleaning ore sand and mineral particles during beneficiation processes (e.g., gold ore, copper ore) to enhance mineral recovery rate.

Water Conservancy Engineering: Purifying sand for dam construction, river regulation, and coastal protection projects, ensuring erosion resistance.

Green Building Materials: Producing eco-friendly sand for recycled concrete, permeable bricks, and other sustainable construction products.

How to Choose the Right Sand Washing Machine

Sand Properties: Consider the type (natural/artificial), particle size, and impurity content (e.g., clay, silt) to choose a machine with suitable cleaning intensity.

Production Capacity: Match the machine’s output (5-500 t/h) to your sand production line’s needs, avoiding underperformance or overcapacity.

Environmental Requirements: Choose water-saving models or equipped with wastewater recycling systems if local regulations have strict pollution control standards.

Installation Space: Compact wheel-type models for small plants; spiral-type models for large-scale operations with sufficient space.