This crushing method makes impact crushers particularly effective for processing medium-hard and brittle materials, such as limestone, granite, concrete, asphalt, and coal. They are available in various sizes and configurations, ranging from small portable units for on-site construction projects to large stationary models for large-scale mining and aggregate operations.

Working Principle of Impact Crushers: How Do They Operate?

Feeding Stage: The raw material is fed into the crusher through a feed hopper, which guides the material evenly onto the rotating rotor. Some models are equipped with a vibrating feeder to ensure a consistent feed rate, preventing overloading and optimizing crushing efficiency.

Impact Crushing Stage: The rotor, driven by a high-power motor, rotates at high speed (usually between 500 and 1,500 rpm). The blow bars or hammers attached to the rotor gain significant kinetic energy, which is transferred to the feed material upon impact. This initial impact shatters the material into smaller pieces.

Secondary Crushing & Refining Stage: The fragmented material is thrown outward by the rotor and collides with the stationary impact plates. This secondary impact further reduces the particle size. Some impact crushers feature adjustable impact plates, allowing operators to control the gap between the rotor and the plates, which directly affects the final product size.

Discharge Stage: After multiple impacts and collisions, the material that meets the required particle size passes through the gap between the impact plates and the rotor, exiting the crusher as the final product. Larger particles that do not meet the standard are retained for further crushing until they reach the desired size.

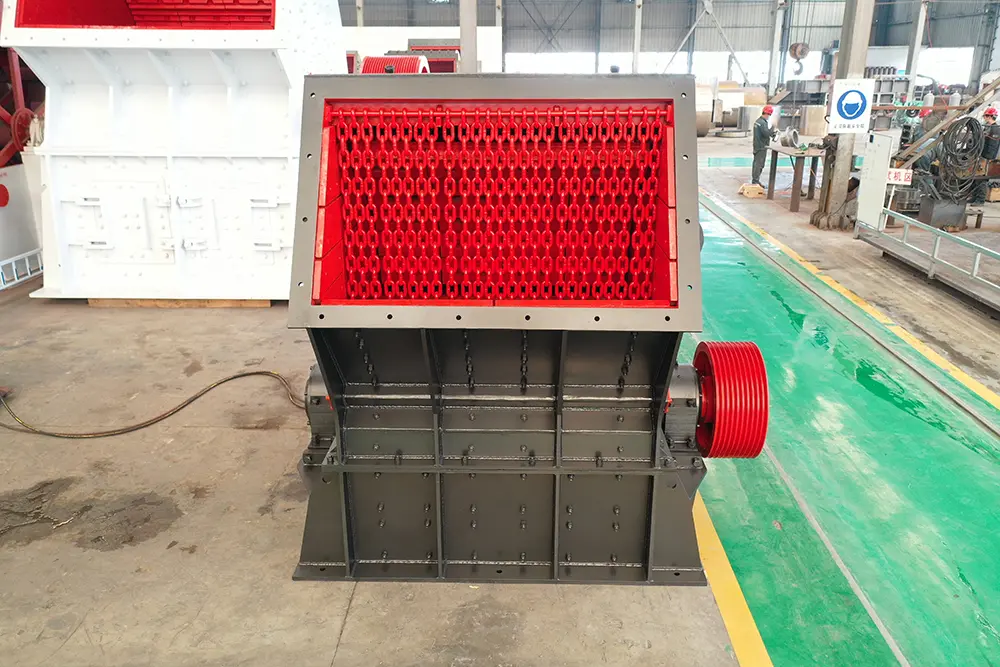

Key Components of an Impact Crusher

Rotor: The heart of the impact crusher, the rotor is a heavy-duty rotating shaft with blow bars or hammers attached. Its design and speed directly determine the crushing capacity and efficiency. High-quality rotors are made of wear-resistant materials to withstand the intense impact of hard materials.

Blow Bars/Hammers: These are the primary wear parts that come into direct contact with the feed material. Blow bars are typically used in horizontal impact crushers (HSI), while hammers are more common in vertical impact crushers (VSI). They need to be replaced periodically to maintain crushing performance.

Impact Plates: Stationary plates located around the rotor, they provide a surface for secondary impact crushing. Adjustable impact plates allow for precise control of the final product size, making the crusher versatile for different applications.

Feed Hopper & Feeder: The feed hopper stores the raw material, while the feeder ensures a steady and uniform supply to the rotor. This prevents uneven loading and reduces the risk of equipment damage.

Discharge Conveyor: Transports the final crushed product away from the crusher, facilitating continuous operation in production lines.

Common Applications of Impact Crushers

Aggregate Production: Impact crushers are ideal for producing concrete aggregates, asphalt aggregates, and road base materials. Their ability to produce well-graded, cubical particles improves the strength and durability of the final construction materials.

Mining Industry: They are used for crushing mineral ores, such as limestone, iron ore, copper ore, and gold ore. In small to medium-sized mines, impact crushers are often used as secondary or tertiary crushers to reduce ore size for further processing.

Construction Demolition: Portable impact crushers are widely used in construction demolition sites to recycle concrete, bricks, and asphalt waste into reusable aggregates. This not only reduces construction waste but also lowers the cost of raw material procurement.

Road & Railway Construction: They are used to crush stones and gravel for road foundations, railway ballast, and other construction projects. The high-quality aggregates produced by impact crushers ensure the stability and durability of transportation infrastructure.

Cement Industry: Impact crushers are used for crushing limestone, clay, and other raw materials in cement production. Their efficient crushing performance helps improve the productivity of cement plants.

Advantages of Impact Crushers Over Other Crushing Equipment

High Crushing Ratio: The impact crushing principle allows for a higher crushing ratio (the ratio of raw material size to final product size) than jaw crushers or cone crushers. This means that impact crushers can reduce large materials to small sizes in fewer stages, reducing equipment investment and production costs.

Superior Product Quality: The impact crushing process produces cubical, well-graded particles with minimal needle-like or flaky shapes. This is particularly important for aggregate production, as cubical particles improve the workability and strength of concrete and asphalt.

Versatility: Impact crushers can handle a wide range of materials, from soft limestone to hard granite. With adjustable impact plates, they can easily adapt to different product size requirements, making them suitable for multiple applications.

High Efficiency & Productivity: The high-speed rotor and efficient impact process enable impact crushers to process large volumes of materials quickly. Their simple structure also allows for easy operation and maintenance, reducing downtime and improving overall productivity.

Cost-Effective Operation: Lower energy consumption, fewer wear parts, and easy maintenance make impact crushers more cost-effective to operate in the long run. Portable models also eliminate the need for material transportation, further reducing costs for on-site projects.