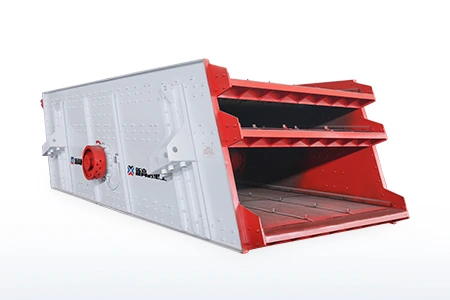

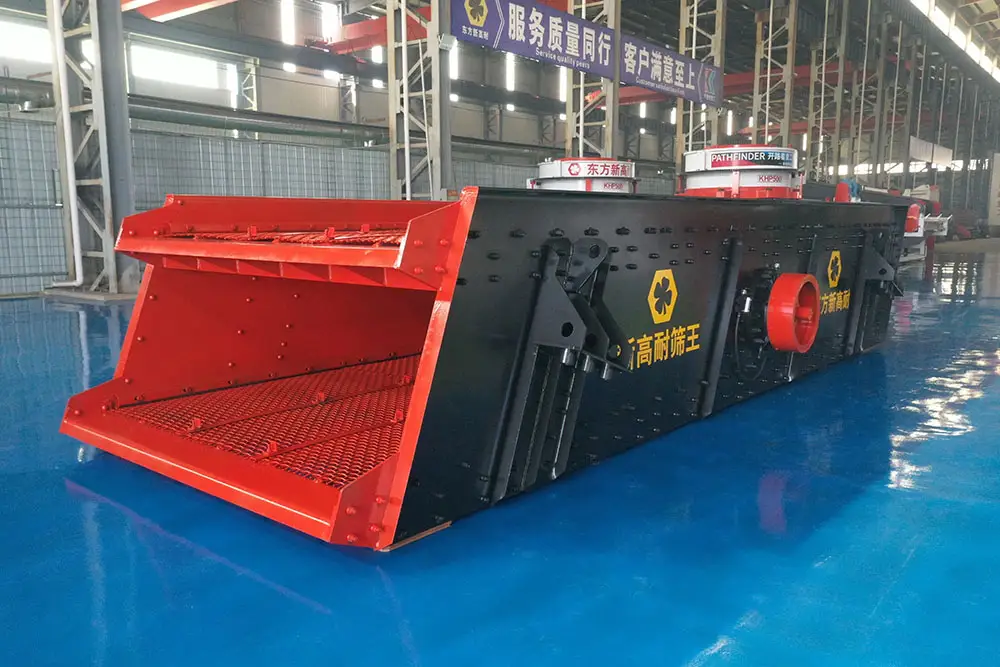

In the vast landscape of industrial processing, sorting and separating materials efficiently is a cornerstone of productivity. One piece of equipment that stands out for its reliability and effectiveness in this task is the vibrating screen. But what is a vibrating screen exactly? This article delves into the definition, working principle, key types, applications, and advantages of vibrating screens, providing a comprehensive overview for professionals and enthusiasts alike.

What Is a Vibrating Screen: Basic Definition

How Does a Vibrating Screen Work?

Vibration Generation: The vibration exciter (usually an electric motor with eccentric weights or a hydraulic/pneumatic vibrator) generates mechanical vibration. The eccentric weights create an unbalanced force, which causes the screen deck to vibrate in a specific pattern—common patterns include circular, linear, or elliptical vibration, each suited for different applications.

Material Feeding: Bulk materials are fed onto the upper end of the inclined screen deck. The inclination of the deck, combined with vibration, guides the materials to move downward along the screen surface.

Particle Separation: As materials move along the vibrating deck, particles smaller than the screen openings fall through the deck (known as “undersize” material), while particles larger than the openings continue moving to the end of the deck (known as “oversize” material). The vibration ensures that even slightly smaller particles pass through, reducing the risk of misclassification.

Collection of Separated Materials: Undersize and oversize materials are collected in separate hoppers or conveyors, ready for further processing or disposal.

Main Types of Vibrating Screens

Linear Vibrating Screen: Features linear vibration, ideal for high-precision classification of fine and medium-grained materials. Widely used in mineral processing, chemical, and food industries.

Circular Vibrating Screen: Produces circular vibration, suitable for coarse screening and dewatering of large bulk materials. Commonly used in quarries, coal mines, and construction sites.

Elliptical Vibrating Screen: Combines the advantages of linear and circular vibration, offering strong penetration for sticky materials and high screening efficiency. Used in metallurgy and ore dressing.

High-Frequency Vibrating Screen: Operates at high vibration frequency, designed for screening fine-grained materials (e.g., powder, sludge). Popular in the pharmaceutical and environmental protection industries.

Key Applications of Vibrating Screens

Mineral Processing: Separating ores into different grades, removing impurities, and dewatering concentrates. Essential in gold, copper, and iron ore mining.

Construction and Aggregates: Screening sand, gravel, and crushed stone to ensure uniform particle size for concrete, asphalt, and road construction.

Coal Industry: Classifying coal by size, removing coal ash, and dewatering coal slime to improve combustion efficiency.

Chemical and Pharmaceutical: Screening chemical powders, pharmaceutical ingredients, and raw materials to ensure product purity and consistency.

Food Processing: Separating food grains (e.g., wheat, rice) from impurities, grading food products by size, and removing foreign particles to meet food safety standards.

Advantages of Using Vibrating Screens

High Screening Efficiency: Vibration accelerates material separation, ensuring a high rate of particle classification compared to static screens.

Versatility: Adaptable to different material types (solid, powder, sludge) and particle sizes, with customizable screen decks and vibration patterns.

Low Maintenance: Simple structure, robust components, and minimal wear (especially with high-quality screen meshes) reduce maintenance costs and downtime.

Energy Efficiency: Modern vibrating screens use energy-saving motors and optimized vibration systems, reducing energy consumption while maintaining performance.

Reduced Clogging: Vibration prevents material buildup on the screen deck, minimizing clogging and ensuring continuous operation.