Gold ore is a precious strategic mineral resource with high economic value, widely used in jewelry, investment, electronics, and aerospace industries. Raw gold ore usually contains gold particles mixed with gangue minerals (quartz, feldspar), sulfide ores (pyrite), and associated precious metals (silver, copper). A professional gold ore beneficiation process is essential to extract pure gold, remove impurities, and improve concentrate grade. Our custom gold ore processing solution is tailored to ore properties (particle size, gold occurrence state, impurity content) and production capacity, adopting gravity separation, flotation, CIL/CIP, and heap leaching technologies to achieve gold recovery rate ≥90%, meeting global gold mining industry quality standards.

Core Beneficiation Processes of Gold Ore

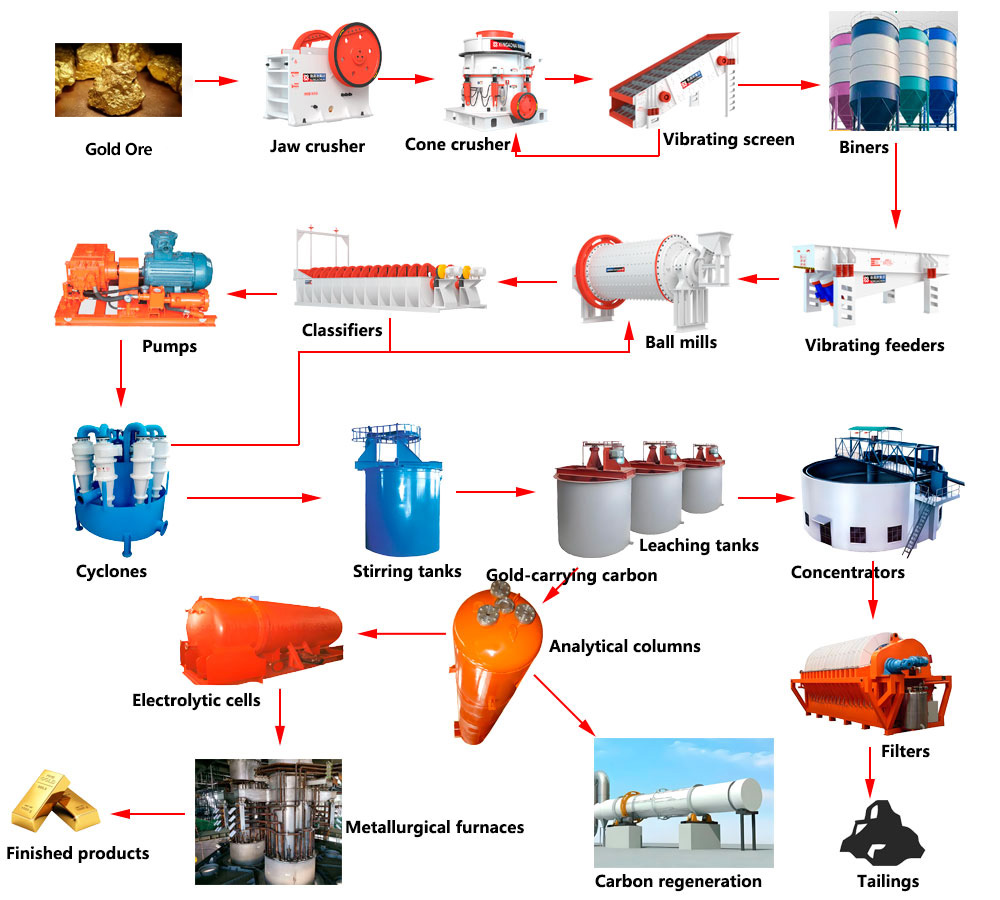

Gold ore beneficiation mainly includes crushing & grinding, mineral liberation, and targeted gold extraction, with extraction methods flexibly selected based on ore type (free-milling gold ore, complex gold ore, low-grade gold ore). The whole process is optimized for high recovery and cost efficiency, with the following core stages:

1. Crushing & Grinding: Core for Gold Mineral Liberation

Raw gold ore (0-1000mm large lumps) undergoes staged crushing and grinding to fully liberate gold particles from gangue, the foundation of efficient gold extraction:

Coarse Crushing: Vibrating feeder uniformly feeds raw ore into jaw crusher to crush large ore into 100-200mm particles, avoiding equipment overload.

Fine Crushing: Cone crusher further crushes ore into 10-20mm fine particles, matching the grinding particle size requirement.

Grinding & Classification: Ball mill grinds crushed ore into fine slurry (particle size ≤0.074mm) to fully release gold particles; spiral classifier/hydrocyclone grades the slurry, qualified slurry enters the extraction stage, and oversized particles are recycled for re-grinding to ensure full mineral liberation.

2. Targeted Gold Extraction: Core Process for High Recovery

According to different gold ore types and occurrence states, we adopt customized extraction technologies to maximize gold recovery rate, the core of gold ore beneficiation process:

✅ Gravity Separation (for free-milling gold ore): Leverages density difference between gold particles and gangue, using jigging machine, shaking table to separate coarse gold particles directly, with simple operation and low cost, suitable for gold ore with visible gold particles.

✅ Flotation Separation (for complex sulfide gold ore): Adds collectors and frothers to the slurry, making gold-bearing sulfide minerals adhere to air bubbles and float to form gold concentrate, then extracts gold from concentrate, ideal for fine-grained gold ore with close symbiosis with sulfide.

✅ CIL/CIP Extraction (for fine-grained gold ore): Cyanide solution leaches gold from slurry into liquid phase, activated carbon adsorbs gold from leachate to form gold-loaded carbon, then elutes and electrolyzes to obtain pure gold, with gold recovery rate ≥92%, the mainstream technology for large-scale gold mining.

✅ Heap Leaching (for low-grade gold ore): Piles low-grade gold ore in heaps, percolates leaching agent through the heap to extract gold, with low investment and simple operation, suitable for low-grade gold ore with large reserves.

3. Concentrate Purification & Tailings Treatment

Gold Concentrate Purification: The gold concentrate obtained by gravity/flotation is further processed via smelting, electrolysis, or chemical purification to produce high-purity gold ingot (Au≥99.99%), meeting industrial application standards.

Environmental Tailings Treatment: Tailings after gold extraction are dewatered by thickener and filter press, the filtered water is recycled to the production system (closed-loop water circulation) to save water resources; tailings are safely stacked with anti-seepage treatment, complying with global environmental regulations (CE, EPA, ISO 14001) to avoid pollution.

Key Equipment Configuration for Gold Ore Beneficiation Line

Our gold ore processing solution integrates high-efficiency, wear-resistant, and energy-saving industrial equipment, tailored to different gold extraction processes, ensuring stable operation and high gold recovery for gold ore processing lines:

Crushing & Feeding Equipment: Vibrating feeder, jaw crusher, cone crusher, circular vibrating screen (for ore grading).

Grinding & Classification Equipment: Ball mill, rod mill, spiral classifier, hydrocyclone (for slurry grading).

Gold Extraction Equipment: Shaking table, jigging machine, flotation machine, CIL/CIP leaching tank, activated carbon adsorption column, heap leaching system, electrolysis device.

Dewatering & Auxiliary Equipment: High-efficiency concentrator, filter press, reagent dosing system, dust removal equipment, closed-loop water circulation system, PLC intelligent control system (automated operation).

Core Advantages of Our Gold Ore Beneficiation Process

Targeting the characteristics of different gold ore types and the high demand for gold recovery rate in mining industry, our customized gold ore beneficiation solution has outstanding competitive advantages:

✅ High Gold Recovery Rate: Optimized process design and professional reagent formula ensure gold recovery rate ≥90% for free-milling gold ore and ≥85% for complex gold ore, 5-10% higher than traditional processes, maximizing resource value.

✅ Strong Ore Adaptability: Custom process solutions for free-milling gold ore, complex sulfide gold ore, low-grade gold ore, oxidized gold ore, and gold ore with associated silver/copper, adaptable to production capacity 50-1000 TPH.

✅ Cost-Effective Operation: Energy-efficient equipment reduces power consumption by 12-20%; optimized reagent dosing and water recycling cut production costs; simple operation reduces labor input.

✅ Environmental & Safety Compliance: Adopt eco-friendly leaching reagents, closed-loop water circulation, dust removal and tailings treatment systems, fully meeting global environmental and safety standards, avoiding environmental risks.

Gold ore beneficiation process is the core link to realize the economic value of gold resources, and the extraction efficiency directly determines the profitability of gold mining projects. Our customized gold ore processing solution, based on ore characteristics and adopting gravity/flotation/CIL/heap leaching technologies, achieves high gold recovery rate, low production cost, environmental protection and safety, and fully meets the needs of different gold mining projects.