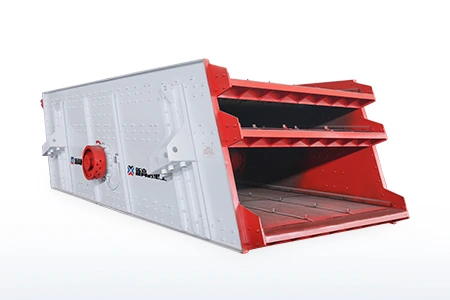

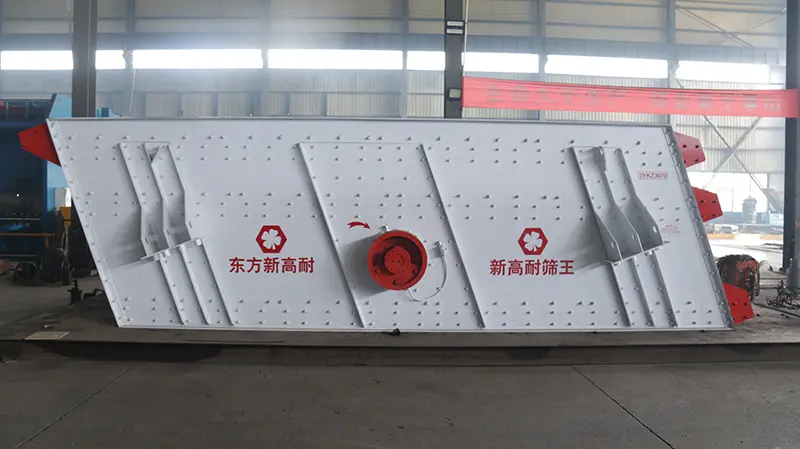

1. Core Components of a Vibrating Screen

Vibration Motor: The power source of the vibrating screen. Equipped with eccentric blocks at both ends, it generates centrifugal force when rotating, which drives the screen body to vibrate. The amplitude and frequency of vibration can be adjusted by changing the angle or weight of the eccentric blocks.

Screen Box: A rigid structure (usually made of steel) that holds the screen mesh. It transmits vibration from the motor to the screen mesh, ensuring materials move evenly across the screening surface.

Screen Mesh: The filtering medium that separates materials by particle size. Available in various materials (steel wire, polyurethane, rubber) and mesh sizes, it is selected based on the required separation precision (e.g., 1mm, 5mm, 20mm).

Vibration Isolation System: Includes springs or rubber pads installed between the screen box and the frame. It reduces vibration transmission to the ground, stabilizes the equipment, and minimizes noise.

Feeding Hopper & Discharge Chutes: The feeding hopper guides bulk materials onto the screen mesh evenly, while multiple discharge chutes collect separated materials of different particle sizes at the bottom.

2. Vibrating Screen Working Principle: Step-by-Step Breakdown

Step 1: Generate Vibration via Motor

Step 2: Material Feeding & Distribution

Step 3: Particle Separation Through Screen Mesh

Fine Particles: Particles smaller than the screen mesh aperture pass through the mesh openings and fall into the corresponding discharge chute (known as “undersize” material).

Coarse Particles: Particles larger than the screen mesh aperture cannot pass through and continue moving along the screen mesh to the end of the screen box, where they are collected by a separate discharge chute (known as “oversize” material).

Step 4: Multi-Layer Screening (for Multi-Deck Screens)

3. Key Factors Influencing the Vibrating Screen Working Principle

Vibration Frequency & Amplitude: Higher frequency (1000-3600 RPM) and smaller amplitude are ideal for separating fine particles, while lower frequency and larger amplitude work better for coarse materials (prevents mesh clogging).

Screen Mesh Aperture & Material: The mesh aperture directly determines the separation size—apertures must match the target particle size. Polyurethane or rubber mesh is more wear-resistant for abrasive materials (e.g., granite), while steel wire mesh is suitable for non-abrasive materials (e.g., limestone).

Material Characteristics: Moisture content, particle shape, and density affect separation. Wet materials may clog the mesh (requiring anti-clogging mesh or vibration adjustment), while irregularly shaped particles may take longer to pass through the mesh.

Feeding Rate: Overfeeding causes material accumulation, reducing screening efficiency; underfeeding wastes capacity. A uniform feeding rate (controlled by a feeder) ensures optimal contact between materials and the screen mesh.

4. Common Types of Vibrating Screens & Their Working Principle Variations

Circular Vibrating Screen: Uses a single vibration motor to generate circular vibration. Suitable for coarse and medium separation (e.g., mining ore primary screening) due to its large processing capacity.

Linear Vibrating Screen: Equipped with two vibration motors rotating in opposite directions, generating linear vibration. Ideal for fine separation (e.g., aggregate grading) as it moves materials forward at a steady speed, ensuring thorough screening.

High-Frequency Vibrating Screen: Operates at high frequency (3000-3600 RPM) and small amplitude. Designed for fine and ultra-fine separation (e.g., mineral beneficiation) to separate particles as small as 0.074mm.

Elliptical Vibrating Screen: Combines circular and linear vibration trajectories. Offers high efficiency and capacity for medium to fine separation (e.g., construction waste recycling).

5. Advantages of Vibrating Screens Based on Their Working Principle

High Separation Efficiency: Vibration ensures materials constantly contact the screen mesh, reducing clogging and improving the passing rate of fine particles (efficiency up to 95% for properly adjusted screens).

Large Processing Capacity: Continuous vibration and even material distribution allow handling of 10-1000 t/h, meeting the needs of large-scale production lines.

Precise Particle Classification: Multi-deck design and adjustable mesh sizes enable accurate separation of multiple particle fractions in one operation.

Adaptability to Diverse Materials: Works with hard, abrasive, wet, or dry materials, from ore and gravel to powders and construction waste.

Simple Operation & Low Maintenance: The core working principle relies on minimal moving parts (motor, screen box, mesh), resulting in easy operation and low maintenance costs.