If you’re involved in construction, mining, or aggregate production, you’ve likely asked: What is a sand making machine? Simply put, a sand making machine (also known as a sand maker or artificial sand production equipment) is a specialized device designed to crush, shape, and refine raw materials into high-quality artificial sand—an essential alternative to natural river sand for construction projects. As natural sand resources become scarce due to over-mining and environmental regulations, sand making machines have become indispensable in modern infrastructure development, delivering consistent, durable sand for concrete, asphalt, and other building materials.

Core Definition: What Is a Sand Making Machine, Exactly?

Key Types of Sand Making Machines

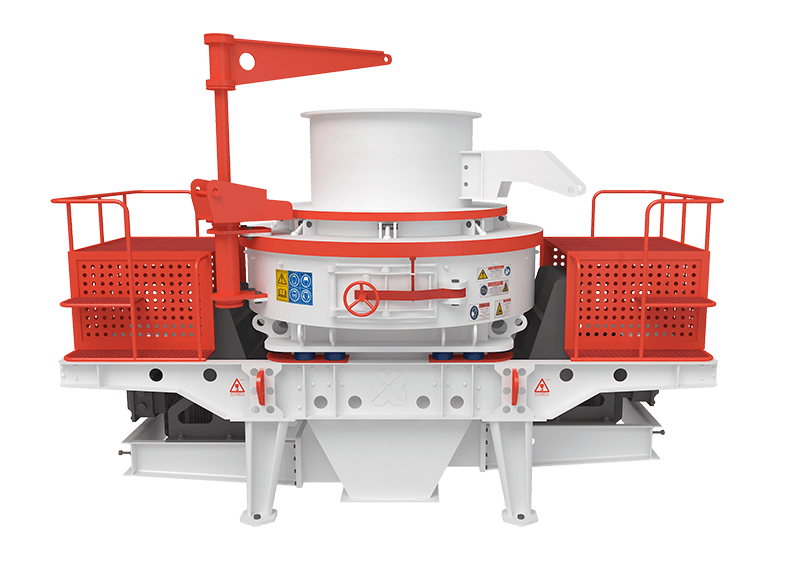

Vertical Shaft Impact (VSI) Sand Making Machine: The most widely used type in commercial production. It uses high-speed rotating impellers to throw materials against a crushing chamber lining (or other materials) for impact crushing and shaping. Ideal for hard materials like granite and basalt, it produces high-quality sand with excellent particle shape.

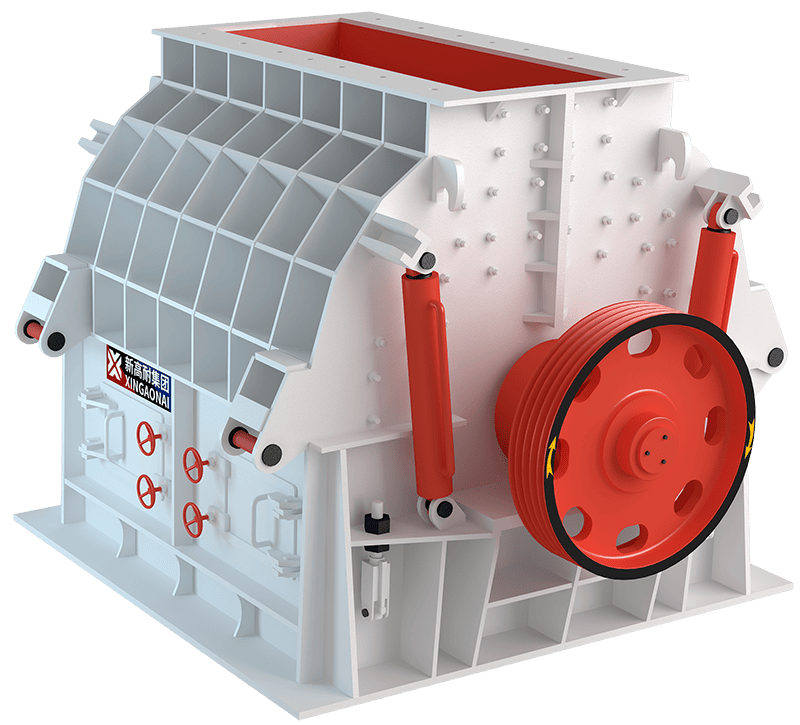

Roller Sand Making Machine: Utilizes two or more rotating rollers to crush and grind materials through extrusion and friction. Suitable for medium-hard to soft materials such as limestone, coal gangue, and clay, it features stable operation, low noise, and uniform particle size output. It’s often used in small to medium-scale sand production lines due to its compact structure.

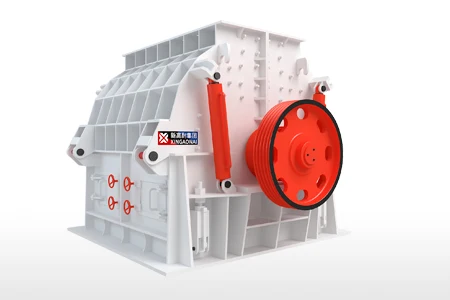

Single-Rotor Sand Making Machine: Equipped with a single rotating rotor fitted with wear-resistant hammers or blow bars. It crushes materials via high-speed impact and shear force, with a simple structure and easy maintenance. Suitable for processing construction waste, river pebbles, and other materials, it’s a cost-effective option for small-scale projects.

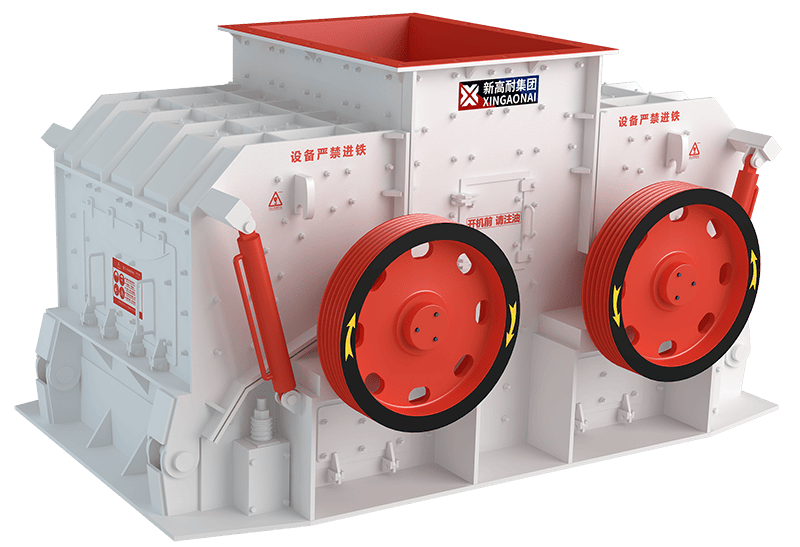

Double-Rotor Sand Making Machine: Integrates two parallel rotors rotating in opposite directions, enabling secondary crushing and shaping in one pass. The dual-rotor design enhances crushing efficiency and improves particle shape, making it ideal for hard materials like basalt and granite. It offers higher throughput than single-rotor models and is suitable for large-scale aggregate production.

How Does a Sand Making Machine Work?

Feeding: Raw materials (coarse aggregates, 50-100mm in size) are fed into the machine via a hopper and evenly distributed into the rotating impeller.

Acceleration & Impact: The impeller rotates at high speed (1000-3000 RPM), accelerating the materials to high velocity before throwing them against the crushing chamber’s lining (or other materials in a “stone-on-stone” mode) with great force. This impact causes the materials to break into smaller particles.

Shaping & Refining: After the initial impact, materials bounce back and collide with each other repeatedly, removing sharp edges and forming rounded grains. This secondary crushing and shaping process ensures the sand meets quality standards.

Screening & Classification: The crushed materials are sent to a screening device. Particles that meet the required sand size (0-5mm) are collected as final products; oversized particles are returned to the sand making machine for reprocessing.

Applications of Sand Making Machines

Construction Industry: Producing sand for concrete, asphalt, mortar, and precast concrete components. Artificial sand from sand making machines improves concrete strength and durability, making it suitable for bridges, high-rise buildings, and highways.

Mining & Quarrying: Processing ore tailings and quarry by-products into usable sand, reducing waste and maximizing resource utilization.

Infrastructure Projects: Supplying sand for road base construction, railway ballast, and water conservancy projects (e.g., dams, reservoirs).

Construction Waste Recycling: Crushing concrete blocks, bricks, and other construction waste into artificial sand, supporting environmental sustainability and circular economy goals.

Key Benefits of Using a Sand Making Machine

Resource Sustainability: Reduces reliance on scarce natural river sand, complying with environmental regulations and protecting ecosystems.

Consistent Quality: Produces sand with uniform particle size, shape, and gradation, ensuring stable performance in construction materials.

High Production Efficiency: Modern sand making machines offer large throughput (10-500 t/h) to meet large-scale project demands.

Cost-Effectiveness: Uses low-cost raw materials (e.g., river pebbles, construction waste) and requires minimal maintenance, lowering overall production costs.