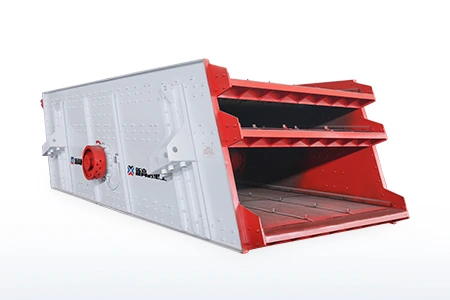

Proper maintenance is critical to maximizing the lifespan, performance, and reliability of a

vibrating screen machine. As a key industrial equipment for material screening and classification, a well-maintained vibrating screen machine minimizes downtime, reduces repair costs, and ensures consistent efficiency in mining, construction, and chemical processes.

This maintenance guide outlines step-by-step practices, checks, and troubleshooting tips tailored specifically for a vibrating screen machine, helping operators and maintenance teams keep the equipment in optimal condition.

Why Regular Maintenance for Vibrating Screen Machine Matters

A vibrating screen machine operates under high-frequency vibration, which puts constant stress on its components—from the vibrator motor to the screen deck and springs. Neglecting maintenance can lead to premature wear, component failure, and unplanned downtime.

Regular maintenance for a vibrating screen machine not only extends its service life but also ensures precise particle classification, reduces energy consumption, and protects other downstream industrial equipment from damage caused by faulty screening.

Daily Maintenance Checklist for Vibrating Screen Machine

Daily maintenance is quick, simple, and essential to catch minor issues before they escalate. Perform these checks at the start and end of each shift to keep your vibrating screen machine running smoothly.

1. Visual Inspection

Check the overall condition of the vibrating screen machine, including the screen deck, frame, feed and discharge chutes. Look for signs of wear, damage, or loose components (e.g., bolts, nuts, or screen mesh).

Ensure there are no foreign objects (e.g., rocks, debris) stuck in the screen mesh or chutes, which can block material flow and damage the vibrating screen machine.

2. Vibration & Noise Check

Run the vibrating screen machine briefly and listen for unusual noises (e.g., grinding, squeaking, or rattling), which may indicate loose components or worn bearings.

Observe the vibration amplitude—uneven or excessive vibration can signal issues with the vibrator motor or springs, affecting the vibrating screen machine’s performance.

3. Lubrication Check

Inspect the lubrication levels of the vibrator motor bearings and other moving parts of the vibrating screen machine. Ensure bearings are properly greased, as insufficient lubrication causes friction and premature wear.

Use the lubricant recommended by the vibrating screen machine manufacturer to avoid component damage.

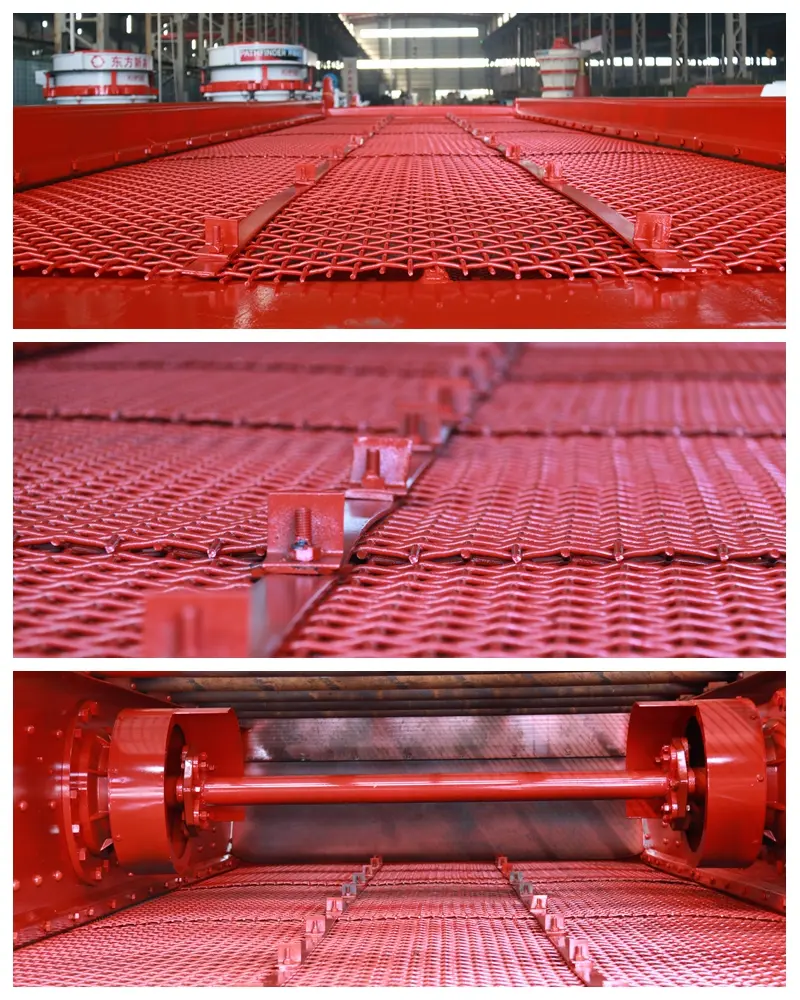

4. Screen Deck Condition

Check the screen deck for tears, holes, or excessive wear. A damaged screen mesh reduces screening efficiency and can lead to incorrect particle classification.

Clean the screen deck of any accumulated material residue, which can clog the mesh and reduce the vibrating screen machine’s throughput.

Periodic Maintenance for Vibrating Screen Machine

In addition to daily checks, perform periodic maintenance (weekly, monthly, or quarterly) based on the

vibrating screen machine’s usage intensity and manufacturer recommendations. This ensures long-term reliability and performance.

1. Weekly Maintenance

Tighten all loose bolts, nuts, and fasteners on the frame, vibrator motor, and screen deck—vibration can loosen these components over time.

Inspect the springs for signs of fatigue, deformation, or damage. Replace any worn springs to maintain consistent vibration and protect the vibrating screen machine’s frame.

Clean the feed and discharge chutes thoroughly to prevent material buildup and blockages.

2. Monthly Maintenance

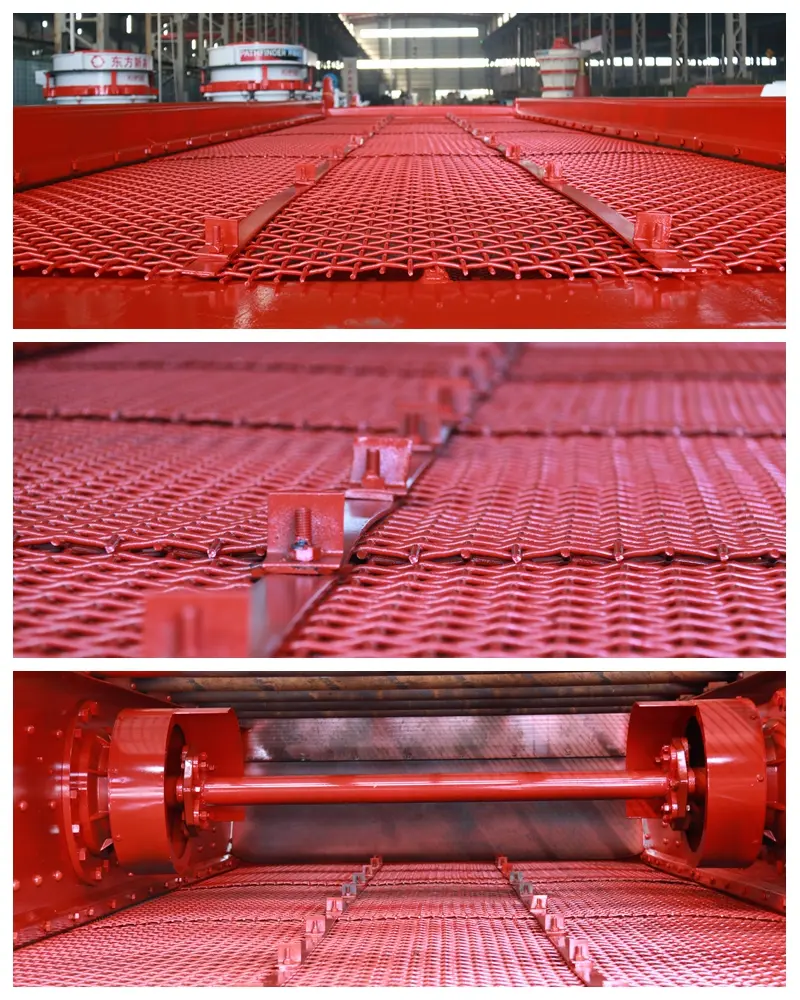

Check the vibrator motor’s condition, including wiring connections and insulation. Ensure the motor is running smoothly without overheating.

Inspect the screen deck tension—loose tension reduces screening efficiency. Adjust or replace the screen mesh if necessary.

Lubricate all moving parts (bearings, shafts) according to the manufacturer’s schedule, using the correct type and amount of lubricant.

3. Quarterly Maintenance

Perform a comprehensive inspection of all components, including the frame, vibrator motor, screen deck, and springs. Replace any worn or damaged parts (e.g., bearings, screen mesh, springs).

Check the alignment of the vibrator motor and screen deck—misalignment can cause uneven vibration and premature wear of the vibrating screen machine.

Clean the entire vibrating screen machine, including hard-to-reach areas, to remove dust, debris, and material buildup.

Common Troubleshooting for Vibrating Screen Machine

Even with regular maintenance, a vibrating screen machine may experience minor issues. Below are common problems, their causes, and quick solutions to minimize downtime.

1. Low Screening Efficiency

Causes: Clogged screen mesh, loose screen tension, incorrect vibration amplitude, or uneven material feed.

Solutions: Clean the screen mesh, adjust screen tension, calibrate the vibrator motor’s eccentric weights, or ensure even material feed to the vibrating screen machine.

2. Excessive Noise or Vibration

Causes: Loose components, worn bearings, damaged springs, or misaligned motor.

Solutions: Tighten loose fasteners, replace worn bearings, install new springs, or realign the vibrator motor of the vibrating screen machine.

3. Screen Deck Damage

Causes: Foreign objects, excessive material load, or worn screen mesh.

Solutions: Remove foreign objects, reduce material load, or replace the damaged screen mesh with a high-quality replacement suitable for your vibrating screen machine.

4. Vibrator Motor Failure

Causes: Insufficient lubrication, overheating, faulty wiring, or worn bearings.

Solutions: Lubricate the motor bearings, check for overheating issues, inspect and repair wiring, or replace worn bearings to restore the vibrating screen machine’s operation.

Best Practices for Vibrating Screen Machine Maintenance

Follow these best practices to optimize maintenance efforts and ensure your vibrating screen machine operates at peak efficiency for years:

1. Follow Manufacturer Guidelines

Always refer to the vibrating screen machine manufacturer’s maintenance manual for specific recommendations on lubrication, component replacement, and maintenance schedules.

2. Train Maintenance Teams

Ensure operators and maintenance personnel are trained to perform proper checks, identify issues, and maintain the vibrating screen machine correctly—this reduces human error and extends equipment life.

3. Keep Maintenance Records

Maintain detailed records of all maintenance activities (daily checks, periodic maintenance, repairs) for the vibrating screen machine. This helps track component wear, identify recurring issues, and plan maintenance schedules.

4. Use High-Quality Replacement Parts

When replacing components (e.g., screen mesh, bearings, springs), use high-quality, manufacturer-approved parts. Low-quality parts can damage the vibrating screen machine and reduce its lifespan.

Conclusion

A well-executed maintenance plan is the key to keeping a

vibrating screen machine running efficiently, reliably, and for a long service life. By following the daily checks, periodic maintenance, and troubleshooting tips outlined in this guide, you can minimize downtime, reduce repair costs, and ensure consistent performance.

Remember, proactive maintenance is more cost-effective than reactive repairs—investing time in maintaining your vibrating screen machine will pay off in improved efficiency, reduced operational costs, and extended equipment lifespan.