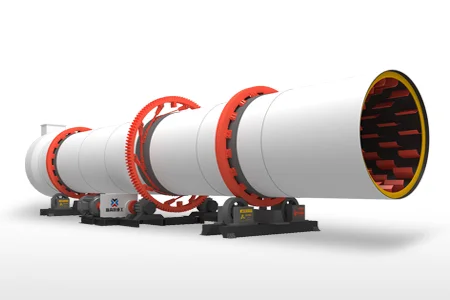

An industrial rotary dryer is a heavy-duty industrial equipment designed to remove moisture from bulk solids, slurries, or powders through continuous thermal processing. It is widely used across various industries that require consistent, efficient drying of materials to improve handling, storage, and downstream processing.

Unlike small-scale dryers, an industrial rotary dryer operates continuously, handling large volumes of materials while maintaining precise moisture control—making it a cornerstone of modern industrial production lines.

Core Components of an Industrial Rotary Dryer

The performance and reliability of an industrial rotary dryer depend on its key components, which work together to ensure efficient heat transfer and uniform drying of materials.

1. Rotating Drum (Shell)

The rotating drum, or shell, is the central component of an industrial rotary dryer. It is a cylindrical tube made of high-grade steel or stainless steel, inclined slightly to allow gravity-assisted material movement through the dryer.

The drum’s interior is often fitted with lifting flights (baffles) that lift and cascade materials, maximizing contact with the drying medium (hot air, gas, or steam).

2. Lifting Flights (Baffles)

Lifting flights, also known as baffles, are mounted inside the rotating drum of an industrial rotary dryer. Their primary role is to agitate and disperse materials, ensuring every particle comes into contact with the drying medium.

The design and arrangement of lifting flights vary based on the material type, ensuring optimal drying efficiency for different bulk solids or slurries.

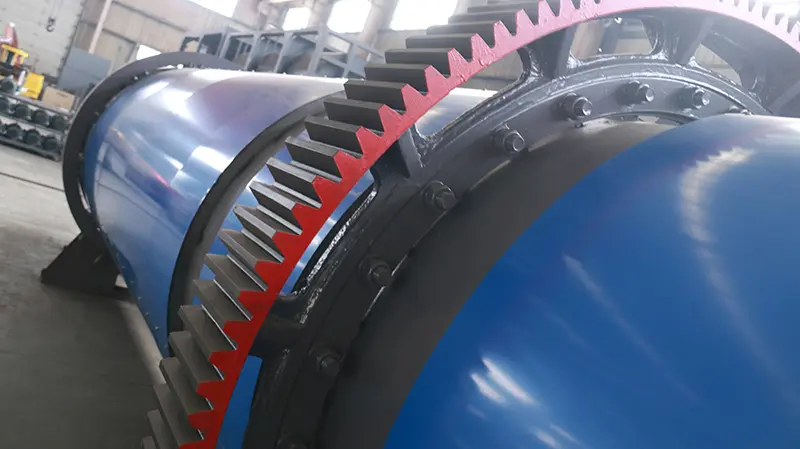

3. Drive System

The drive system powers the rotation of the industrial rotary dryer’s drum, consisting of an electric motor, gear reducer, rollers, and tires. It controls the drum’s rotational speed, which is critical for adjusting drying time.

Variable speed drives (VSDs) are often integrated to allow flexibility, enabling operators to tailor rotation speed to the material’s moisture content and drying requirements.

4. Heating System

The heating system of an industrial rotary dryer generates the thermal energy needed to evaporate moisture from materials. Common heating sources include natural gas, propane, coal, biomass, or waste heat from other industrial processes.

A burner or heat exchanger heats the drying medium (air or gas), which is then directed into the rotating drum to transfer heat to the wet materials.

5. Airflow System

The airflow system ensures the continuous circulation of the drying medium through the industrial rotary dryer. It includes fans, ductwork, and a cyclone or dust collector to remove particulate matter from the exhaust air.

Proper airflow is essential for carrying away evaporated moisture and maintaining a consistent drying environment inside the drum.

6. Feed & Discharge Systems

The feed system delivers wet materials into the industrial rotary dryer’s drum, typically using a conveyor, screw feeder, or chute. It ensures a steady, uniform feed rate to maintain drying consistency.

The discharge system, located at the lower end of the inclined drum, collects dried materials and transfers them to downstream processing or storage.

Working Principle of an Industrial Rotary Dryer

The working principle of an industrial rotary dryer revolves around continuous heat transfer between the drying medium and the wet materials, facilitating moisture evaporation and removal.

Wet materials are fed into the higher end of the inclined rotating drum. As the drum rotates, lifting flights lift the materials and cascade them downward, exposing them to the hot drying medium flowing through the drum (either co-current or counter-current).

Heat from the drying medium is transferred to the wet materials, evaporating surface moisture and internal moisture. The evaporated moisture is carried away by the airflow, while the dried materials move toward the lower end of the drum and exit through the discharge system.

The entire process is continuous, allowing the industrial rotary dryer to handle large volumes of materials efficiently while maintaining precise moisture levels in the final product.

Key Benefits of Using an Industrial Rotary Dryer

Industrial rotary dryers offer significant advantages over other drying equipment, making them indispensable in industrial processes that require large-scale, consistent drying.

1. High Drying Efficiency & Capacity

An industrial rotary dryer operates continuously, handling large volumes of materials (from tons to hundreds of tons per hour) with high drying efficiency. The cascading action of lifting flights maximizes heat transfer, reducing drying time.

2. Uniform Drying Results

The combination of consistent rotation, uniform airflow, and optimized lifting flight design ensures that all materials are dried evenly. This eliminates moisture variations in the final product, improving quality and downstream process efficiency.

3. Versatility & Adaptability

An industrial rotary dryer can handle a wide range of materials, including minerals, ores, chemicals, agricultural products, and construction materials. It can be adapted to different moisture contents, particle sizes, and drying requirements by adjusting drum speed, airflow, and temperature.

4. Durability & Reliability

Built with heavy-duty steel components and robust design, an industrial rotary dryer is engineered to withstand harsh industrial environments, high temperatures, and continuous operation. It requires minimal maintenance, ensuring long service life and reliable performance.

5. Energy Efficiency

Modern industrial rotary dryers are designed with energy-saving features, such as heat recovery systems that reuse exhaust heat, and optimized airflow designs that reduce energy consumption. This lowers operational costs for industrial facilities.

Industrial Applications of Industrial Rotary Dryer

Thanks to their versatility, efficiency, and reliability, industrial rotary dryers are widely used across diverse industrial sectors, playing a critical role in material processing.

1. Mining & Mineral Processing

In the mining industry, industrial rotary dryers are used to dry ores, minerals, and aggregates (e.g., limestone, coal, iron ore) after washing or beneficiation. Drying improves material handling, reduces transportation costs, and enhances downstream processing (e.g., grinding, smelting).

2. Chemical Industry

Chemical manufacturers use industrial rotary dryers to dry chemical powders, granules, and slurries (e.g., fertilizers, pigments, detergents). Consistent drying ensures product stability, purity, and compliance with industry standards.

3. Agricultural & Food Processing

In agriculture and food processing, industrial rotary dryers dry grains, seeds, pulses, and food by-products. Drying prevents spoilage, extends shelf life, and improves storage and transportation capabilities.

4. Construction & Building Materials

Construction material producers use industrial rotary dryers to dry sand, gravel, cement, and asphalt aggregates. Drying removes excess moisture, ensuring optimal performance of concrete, asphalt, and other construction materials.

5. Waste Management & Recycling

In waste management, industrial rotary dryers dry municipal solid waste, sludge, and recyclable materials. Drying reduces waste volume, eliminates pathogens, and makes waste easier to handle, transport, or process into energy or reusable products.

Conclusion

An industrial rotary dryer is a vital industrial equipment that enables efficient, continuous drying of bulk materials across diverse sectors. Its robust components, reliable working principle, and versatile design make it indispensable for improving product quality, reducing operational costs, and optimizing industrial processes.

Whether used for drying minerals in mining, chemicals in manufacturing, or grains in agriculture, an industrial rotary dryer delivers consistent, high-performance results—making it a cornerstone of modern industrial production.