Core Components of a Linear Vibrating Feeder

The reliable performance of a linear vibrating feeder relies on a set of robust, coordinated components, each designed to support vibration generation, material movement, and structural stability. All parts are built with industrial-grade materials to withstand continuous operation and harsh working environments.

1. Vibration Exciter

The vibration exciter is the power core of a linear vibrating feeder, responsible for generating the high-frequency linear vibration that drives material flow. It typically consists of two eccentric shafts with gears that rotate in opposite directions, creating a horizontal inertial force that propels materials forward. The exciter can be adjusted to modify vibration amplitude and frequency, allowing precise control of material feeding speed.

2. Feeding Trough

The feeding trough is the primary surface where material transport occurs, a rigid, U-shaped or flat metal trough made of steel, stainless steel, or wear-resistant alloy. Its inner surface is often polished or lined with anti-wear material to reduce friction and prevent material buildup, ensuring smooth, continuous flow. The trough’s length and width are customized based on material type and feeding volume requirements.

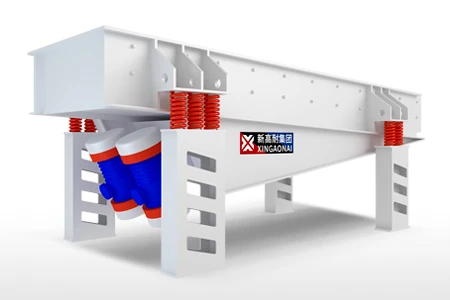

3. Spring Support System

A set of heavy-duty coil springs forms the support system of a linear vibrating feeder, mounting the feeding trough and vibration exciter on the base frame. The springs absorb vertical vibration, isolate the feeder’s vibration from the ground and surrounding equipment, and maintain the stable linear motion of the trough. They also reduce noise and prevent structural damage to the installation site.

4. Base Frame

The base frame is the structural foundation of the linear vibrating feeder, a sturdy steel frame that secures the spring support system and vibration exciter. It distributes the feeder’s weight evenly and provides a stable mounting base for installation on factory floors, concrete foundations, or mobile equipment. The frame is designed to resist deformation under continuous vibration and heavy material loads.

5. Drive Motor

The drive motor supplies power to the vibration exciter, typically a three-phase asynchronous motor with high torque and reliable performance. It is connected to the exciter via a coupling or belt drive, and variable frequency drives (VFDs) can be integrated to adjust motor speed, further fine-tuning the feeder’s feeding rate for different processing needs.

6. Sealing & Protective Parts

For applications involving dusty, corrosive, or wet materials, linear vibrating feeders are equipped with sealing gaskets and protective covers. These parts prevent material leakage, dust accumulation, and moisture damage to the vibration exciter and motor, extending the feeder’s service life and ensuring safe operation.

Working Principle of a Linear Vibrating Feeder

The linear vibrating feeder operates on the principle of synchronous inertial vibration, converting rotational mechanical energy into linear reciprocating vibration to move materials forward. When the drive motor powers the vibration exciter, its two eccentric shafts rotate in sync and opposite directions, producing a combined inertial force that acts horizontally along the feeder’s trough. This force causes the feeding trough to vibrate back and forth in a straight line at a fixed frequency and amplitude. As the trough vibrates, material particles on its surface are repeatedly lifted slightly and then dropped forward by gravity, creating a continuous, uniform sliding or bouncing motion of the material along the trough. The feeding speed and volume are easily adjustable by modifying the vibration amplitude (via eccentric weight adjustment) or motor speed (via VFD), allowing the feeder to match the throughput requirements of downstream industrial equipment perfectly. The entire process is contactless with no moving parts in direct contact with the material, minimizing wear and material damage.

Key Benefits of Using a Linear Vibrating Feeder

A linear vibrating feeder offers significant advantages over conventional material feeding equipment, making it the preferred choice for efficient, reliable industrial material handling across diverse sectors. Its design prioritizes performance, flexibility, and low operational costs.

1. Consistent & Precise Feeding

The linear vibrating feeder delivers a uniform material flow with adjustable feeding speed and volume, ensuring accurate material supply to downstream equipment. This precision eliminates overfeeding or underfeeding, optimizing process efficiency and product quality in crushing, screening, and mixing operations.

2. Versatile Material Adaptability

It can handle almost all bulk and granular materials, including fine powders (e.g., cement, flour), small granules (e.g., plastic pellets, fertilizer), and large aggregates (e.g., stone, ore). The feeder can be customized with different trough liners and vibration parameters to adapt to abrasive, fragile, or sticky materials without clogging.

3. Low Energy Consumption & Noise

With a simple mechanical structure and efficient vibration generation, the linear vibrating feeder consumes minimal electricity compared to other feeders. The spring support system isolates vibration, reducing operational noise to below industrial standards, creating a quieter working environment.

4. Low Maintenance & Long Service Life

The feeder has few moving parts and no direct material-contact wear components, resulting in minimal maintenance requirements. All core components are built with industrial-grade, wear-resistant materials, ensuring long-term continuous operation and reducing repair and replacement costs.

5. Gentle Material Handling

The low-amplitude, high-frequency vibration moves materials without harsh impact or friction, preventing breakage, degradation, or segregation of fragile materials (e.g., food grains, ceramic pellets). This gentle handling preserves material integrity and quality.

6. Compact & Flexible Design

Linear vibrating feeders feature a compact footprint, making them suitable for installation in tight factory spaces or on mobile processing equipment (e.g., portable crushing plants). They can be mounted horizontally or at a small incline, and customized trough sizes fit specific production line layouts.

Industrial Applications of a Linear Vibrating Feeder

Thanks to its efficiency, versatility, and reliability, the linear vibrating feeder is widely used in nearly all industrial sectors that require continuous, precise material feeding and conveying. It integrates seamlessly into production lines, acting as a critical link between material storage and processing.

1. Mining & Mineral Processing

In mining, linear vibrating feeders transport ores, coal, and aggregates from hoppers to crushers, vibrating screens, and grinding mills. They handle heavy, abrasive materials with high feeding volumes, optimizing the efficiency of mineral extraction and processing.

2. Construction & Building Materials

Construction material plants use the feeder to convey sand, gravel, cement, and concrete aggregates to batching plants and mixing equipment. It ensures accurate material proportioning, improving the quality of concrete, asphalt, and other building materials.

3. Chemical & Pharmaceutical Industry

For chemical and pharmaceutical production, linear vibrating feeders transport fine powders, chemical granules, and pharmaceutical raw materials to mixers, dryers, and packaging machines. Sanitary stainless steel troughs are used for food-grade and pharmaceutical applications, complying with hygiene standards.

4. Food & Beverage Processing

In the food industry, the feeder handles grains, seeds, nuts, and processed food particles, feeding them to sorting, packaging, and processing equipment. Its gentle material handling preserves food integrity, and the anti-corrosive design resists contamination from food products.

5. Recycling & Waste Management

Waste management facilities use linear vibrating feeders to sort and convey recyclable materials (e.g., plastic, metal, paper) and municipal solid waste to shredders and separators. The feeder’s clog-free design handles mixed, irregular materials efficiently.

6. Metallurgical & Foundry Industry

Metallurgical plants use the feeder to transport metal ores, scrap metal, and molten metal additives to smelting furnaces and casting equipment. High-temperature resistant trough liners are used to withstand the harsh, high-heat environment of metallurgical processing.

Conclusion

A linear vibrating feeder is an indispensable industrial equipment for efficient, precise, and reliable material handling, serving as the critical "connecting link" in modern production lines across mining, construction, chemical, food, and other sectors. Its simple yet robust design, consistent feeding performance, and versatile material adaptability make it ideal for transporting all types of bulk and granular materials, while its low energy consumption, low maintenance, and gentle material handling reduce operational costs and preserve material quality. By adjusting vibration parameters to match downstream process requirements, the linear vibrating feeder optimizes production line efficiency, eliminates material waste, and ensures seamless material flow from storage to processing. For any industrial operation requiring continuous material feeding, a linear vibrating feeder is a cost-effective, high-performance solution that delivers long-term reliability and consistent results.