When your industrial operation requires efficient material separation, investing in the right vibrating screen is crucial. With numerous options of

vibrating screen for sale on the market, from compact models for small-scale projects to heavy-duty units for mining and aggregates, navigating the choices can be overwhelming. The key is to balance quality, performance, and budget while ensuring the equipment aligns with your specific application. This guide breaks down everything you need to know about selecting and purchasing a vibrating screen for sale, helping you make a confident, value-driven decision.

Types of Vibrating Screens for Sale: Choose the Right Model

Vibrating screens come in various designs, each optimized for specific materials, particle sizes, and industry needs. Understanding the different types available will help you narrow down the best vibrating screen for sale for your operation:

1. Circular Vibrating Screen

One of the most popular options for vibrating screen for sale, the circular vibrating screen uses a rotating eccentric block to generate circular vibration. This design ensures uniform material distribution and high screening efficiency, making it ideal for coarse and medium-grain materials like coal, ore, and aggregates. It’s widely used in mining, construction, and recycling due to its simple structure, easy maintenance, and strong adaptability. When searching for a circular vibrating screen for sale, look for models with adjustable vibration amplitude to suit different material characteristics.

2. Linear Vibrating Screen

The linear vibrating screen features linear vibration generated by dual vibration motors, allowing materials to move forward in a straight line. This type of vibrating screen for sale excels at fine-grain screening and dewatering, making it suitable for industries like food processing, chemical engineering, and mineral processing. It offers precise classification, low noise, and stable operation. If you’re screening fine powders or need strict particle size control, a linear vibrating screen for sale is a top choice—opt for models with customizable mesh sizes for added flexibility.

3. High-Frequency Vibrating Screen

Designed for ultra-fine material separation, the high-frequency vibrating screen for sale uses high-frequency, low-amplitude vibration to separate particles as small as 0.074mm. It’s commonly used in mineral processing (e.g., separating gold, silver, or copper ores) and chemical industries where precise classification is critical. This model minimizes mesh clogging and improves separation efficiency, though it requires more careful maintenance of the vibration motor. When browsing high-frequency vibrating screens for sale, prioritize units with durable, corrosion-resistant decks.

4. Double Deck/Triple Deck Vibrating Screen

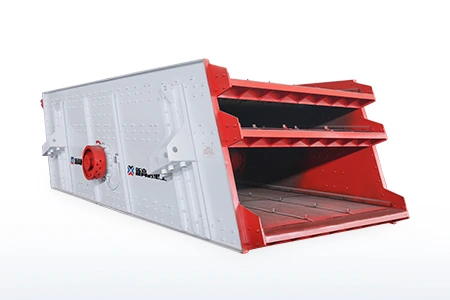

For operations needing multi-stage screening, a double or triple deck

vibrating screen for sale is ideal. These models feature stacked decks with different mesh sizes, enabling simultaneous separation of materials into multiple fractions (e.g., oversize, mid-size, undersize). They save space and boost productivity, making them a favorite in aggregate plants and large-scale recycling facilities. When evaluating this type of vibrating screen for sale, check the deck load capacity and adjustability to ensure it meets your throughput needs.

5. Dewatering Vibrating Screen

If your application involves wet materials (e.g., sand washing, coal dewatering), a dewatering vibrating screen for sale is essential. This model uses specialized vibration patterns and inclined decks to remove excess moisture from materials, reducing drying costs and improving product quality. It’s widely used in sand and gravel plants, mining, and environmental engineering. Look for dewatering vibrating screens for sale with wear-resistant polyurethane decks, which offer better water drainage and longer service life.

Key Factors to Consider When Buying a Vibrating Screen for Sale

Not all vibrating screens for sale are created equal. To ensure you invest in equipment that delivers long-term value, focus on these critical factors:

1. Application and Material Requirements

Start by defining your specific needs: What material will you be screening (e.g., ore, sand, waste)? What is the material’s particle size range, moisture content, and abrasiveness? For example, abrasive materials like iron ore require a vibrating screen with thick, wear-resistant components, while wet materials need anti-clogging mesh. Clarifying these details will help you avoid purchasing a vibrating screen for sale that’s ill-suited to your operation.

2. Throughput Capacity

Throughput (measured in tons per hour) is a non-negotiable factor. A vibrating screen for sale must match your production targets—too small, and it will bottleneck your workflow; too large, and it will waste energy and money. Ask suppliers for capacity charts based on your material type and desired screen size, and opt for models with a slight capacity buffer to accommodate future production growth.

3. Build Quality and Durability

The lifespan of a vibrating screen depends on its construction. When evaluating a vibrating screen for sale, inspect the frame (preferably steel for rigidity), screen deck material (steel, polyurethane, or rubber), and vibration components (bearings, motors). Reputable manufacturers use high-grade materials and strict quality control—avoid cheap vibrating screens for sale that cut corners, as they will require frequent repairs and replacement, increasing long-term costs.

4. Energy Efficiency and Operating Costs

Energy consumption is a major ongoing cost for industrial equipment. Look for a vibrating screen for sale with energy-efficient motors (e.g., IE3 or IE4 rated) that reduce electricity bills without sacrificing performance. Also, consider maintenance costs—models with easy-to-replace parts (e.g., mesh, bearings) and accessible components will minimize downtime and labor expenses.

5. Customization Options

Every operation is unique, so a one-size-fits-all vibrating screen may not suffice. Many suppliers offer customized vibrating screens for sale, allowing you to adjust deck size, mesh type, vibration parameters, and even frame design. For example, if you have limited space, you can request a compact model; if you screen corrosive materials, you can opt for stainless steel components. Prioritize suppliers that offer tailored solutions when searching for a vibrating screen for sale.

6. After-Sales Support and Warranty

A reliable vibrating screen for sale should come with comprehensive after-sales support. Ask suppliers about their warranty terms (e.g., 1-2 years for parts and labor), availability of replacement components, and technical support services (e.g., on-site installation, maintenance training). Avoid suppliers that offer no warranty or poor customer service—if your screen breaks down, delays in support can cost your business thousands in downtime.

Where to Find High-Quality Vibrating Screens for Sale

Knowing where to buy a vibrating screen is just as important as choosing the right model. Here are the most reliable channels for finding a high-quality vibrating screen for sale:

1. Direct from Manufacturers

Purchasing a

vibrating screen for sale directly from the manufacturer offers several advantages: lower prices (no middleman markup), access to customization, and direct technical support. Many manufacturers have online catalogs where you can browse their vibrating screens for sale and request quotes. Look for manufacturers with a strong industry reputation—check for certifications (e.g., ISO 9001) and customer reviews to verify their credibility.

2. Authorized Distributors

Authorized distributors partner with top manufacturers to sell vibrating screens for sale locally. They offer the benefit of in-person product inspections, faster delivery (due to local inventory), and on-site support. Distributors are ideal if you prefer face-to-face communication or need a vibrating screen for sale quickly. Ensure the distributor is officially authorized to avoid counterfeit or low-quality equipment.

3. Online Industrial Marketplaces

Online platforms like Alibaba, Amazon Business, or industry-specific marketplaces (e.g., Mining Equipment Marketplace) list thousands of vibrating screens for sale from global suppliers. These platforms allow you to compare prices, read reviews, and connect with suppliers easily. However, exercise caution—only buy from verified sellers with positive ratings, and request product samples or factory audits if possible to ensure quality.

4. Used Equipment Dealers

If you’re on a tight budget, a used vibrating screen for sale can be a cost-effective option. Used equipment dealers specialize in refurbished or pre-owned screens that have been inspected and repaired to ensure functionality. This is a good choice for small businesses or short-term projects. However, always check the equipment’s maintenance history, age, and remaining lifespan, and ask for a short warranty to cover potential issues.

Tips for Getting the Best Deal on a Vibrating Screen for Sale

To maximize value when purchasing a vibrating screen for sale, follow these practical tips:

Compare Multiple Quotes: Request quotes from 3-5 suppliers for the same type of vibrating screen for sale. This will help you identify fair pricing and avoid overpaying. Be sure to compare apples to apples—ensure each quote includes the same specifications, accessories, and warranty terms.

Negotiate for Bundled Services: Many suppliers are willing to offer discounts if you bundle the vibrating screen for sale with additional services like installation, training, or extended warranties. Don’t be afraid to negotiate—suppliers want to secure your business, especially for larger orders.

Consider Bulk Purchases: If you need multiple vibrating screens, buying in bulk can lead to significant price reductions. Suppliers often offer volume discounts, so mention your total requirements upfront.

Avoid “Too-Good-to-Be-True” Prices: While everyone wants a cheap vibrating screen for sale, prices that are far below the market average often indicate poor quality. Investing a little more in a reputable model will save you money on repairs and downtime in the long run.

Check for Promotions: Many manufacturers and distributors run seasonal promotions or clearance sales on vibrating screens for sale. Follow industry newsletters or supplier social media pages to stay updated on deals.

Common Mistakes to Avoid When Buying a Vibrating Screen for Sale

To ensure a smooth purchase, steer clear of these common pitfalls:

Ignoring Material Compatibility: Buying a vibrating screen for sale without considering your material’s properties (e.g., moisture, abrasiveness) will lead to poor performance and frequent breakdowns.

Sacrificing Quality for Price: Opting for the cheapest vibrating screen for sale may save money upfront, but it will cost more in the long run due to repairs and reduced productivity.

Overlooking After-Sales Support: A lack of reliable after-sales support can leave you stranded if your screen malfunctions. Always confirm the supplier’s support capabilities before purchasing.

Not Testing the Equipment: Whenever possible, test the vibrating screen for sale before buying. If you can’t visit the supplier in person, ask for a video demonstration of the equipment in operation.

Conclusion: Invest in the Right Vibrating Screen for Sale

Purchasing a

vibrating screen for sale is a significant investment, but with the right knowledge, you can select equipment that boosts efficiency, reduces costs, and lasts for years. Start by defining your application needs, exploring the different types of vibrating screens available, and evaluating suppliers based on quality, support, and price. By following the guidelines in this guide, you’ll be able to find a high-quality vibrating screen for sale that meets your operational requirements and delivers maximum value. Remember— the best vibrating screen isn’t always the cheapest; it’s the one that aligns perfectly with your business goals.