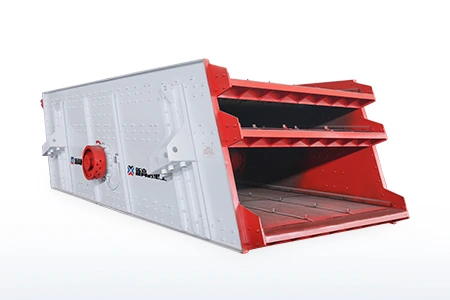

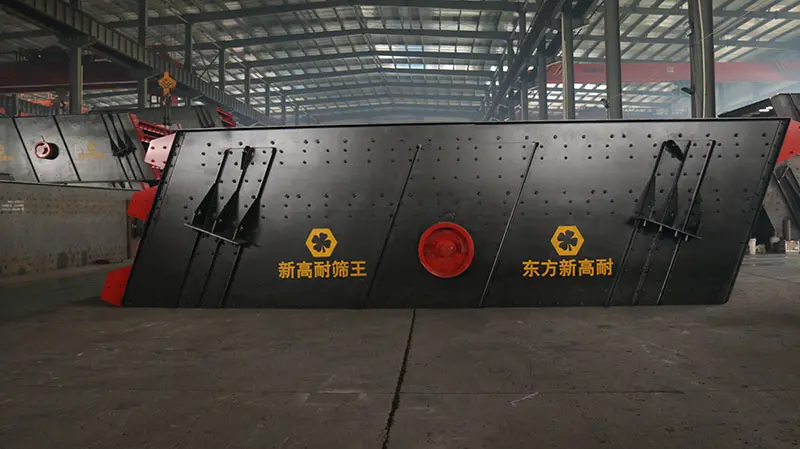

A double deck vibrating screen is widely used in mining, aggregates, quarrying, construction, and recycling industries where high screening efficiency and precise material separation are required. With two screening layers operating simultaneously, this type of vibrating screen significantly increases processing capacity while maintaining accurate particle size classification.

What Is a Double Deck Vibrating Screen?

A double deck vibrating screen is a screening machine equipped with two screen decks arranged vertically. Each deck uses different mesh sizes to separate materials into multiple size fractions in a single operation. Compared with single deck screens, a double deck vibrating screen improves productivity and reduces the need for additional screening equipment.

Working Principle of a Double Deck Vibrating Screen

The double deck vibrating screen operates through vibration generated by vibration motors or an exciter. Material is fed onto the top deck, where larger particles are separated. The remaining material then passes to the lower deck for further classification. Continuous vibration ensures efficient material movement, stratification, and separation across both decks.

Key Advantages of a Double Deck Vibrating Screen

Using a double deck vibrating screen offers several operational benefits:

Higher screening capacity with compact equipment design

Multiple material size separation in one process

Reduced equipment footprint and installation cost

Improved screening accuracy and efficiency

Lower operating and maintenance costs

These advantages make the double deck vibrating screen ideal for high-throughput production lines.

Applications of Double Deck Vibrating Screens

A double deck vibrating screen is suitable for a wide range of materials and industries, including:

Mining and mineral processing

Sand and aggregate production

Quarry and stone crushing plants

Recycling and waste separation

Construction material classification

Its versatility allows it to handle dry or wet materials under various operating conditions.

Design and Customization Options

Modern double deck vibrating screen designs can be customized based on production requirements. Key design options include:

Different vibration types (linear, circular, elliptical)

Various screen media (wire mesh, polyurethane, rubber)

Adjustable deck angles and vibration parameters

Heavy-duty frames for high-impact applications

Customization ensures optimal performance and long service life.

Maintenance and Reliability

Proper maintenance is essential to ensure reliable operation of a double deck vibrating screen. Regular inspection of screen panels, vibration motors, bearings, and fasteners helps prevent unplanned downtime. Routine lubrication and timely replacement of wear parts significantly extend equipment lifespan and maintain stable screening efficiency.

Conclusion

A double deck vibrating screen is an efficient and cost-effective solution for operations requiring high capacity and precise material separation. With its dual-layer design, flexible customization, and reliable performance, it is an ideal choice for improving productivity and optimizing screening processes across multiple industries.