Why Prioritize Hydraulic Cone Crusher Maintenance? Understanding the Core Benefits

Maximized Operational Uptime: Unexpected breakdowns can halt production for hours or even days, resulting in significant revenue losses. Routine maintenance identifies and addresses minor issues before they escalate into major failures, ensuring continuous operation.

Reduced Repair Costs: Replacing a worn bearing or sealing a small hydraulic leak is far more cost-effective than repairing a damaged crankshaft, cracked frame, or failed hydraulic system. Preventive maintenance eliminates the need for expensive emergency repairs.

Consistent Crushing Performance: A well-maintained crusher maintains precise settings, uniform particle size output, and optimal crushing efficiency. This consistency is essential for meeting product quality standards and customer requirements.

Enhanced Safety: Faulty components—such as loose fasteners, leaking hydraulic fluid, or malfunctioning safety guards—pose serious risks to operators. Maintenance ensures all safety features are functional and the crusher operates within safe parameters.

Extended Equipment Lifespan: Proper care of critical components (e.g., cones, liners, hydraulic pumps) slows down wear and tear, allowing the crusher to serve your operations for years beyond its expected lifespan.

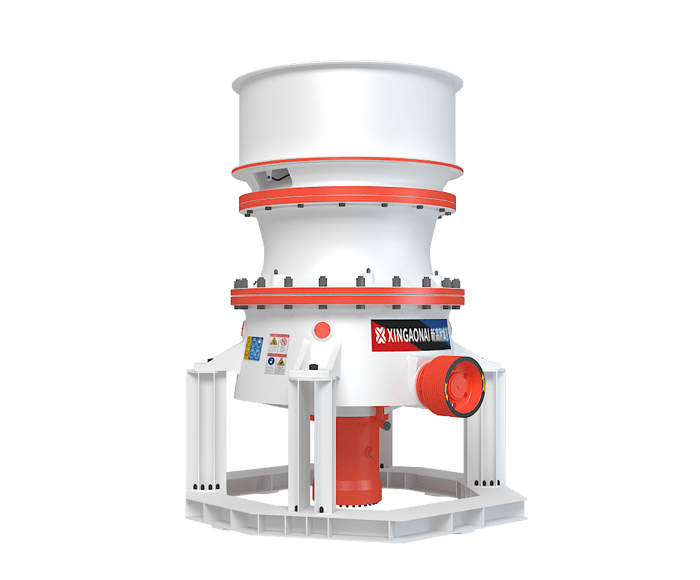

Key Components of Hydraulic Cone Crushers: Focus Areas for Maintenance

1. Crushing Chamber (Cones and Liners)

Daily inspection for wear, cracks, or deformation. Look for uneven wear patterns, which may indicate misalignment.

Regularly check and tighten liner fasteners to prevent movement during operation, which can cause further damage.

Replace liners when wear reaches the manufacturer’s recommended threshold (typically 70-80% wear) to avoid damage to the cone itself.

Ensure proper alignment of the cones to maintain uniform crushing and prevent excessive wear on one side.

2. Hydraulic System

Check hydraulic fluid levels daily and top up with the manufacturer-specified fluid (never mix different types).

Inspect hoses, pipes, and seals for leaks, bulges, or cracks. Replace damaged components immediately to prevent fluid loss and contamination.

Change hydraulic filters at regular intervals (usually every 500-1,000 operating hours) to remove contaminants that can damage pumps and valves.

Monitor fluid temperature—excessive heat (above 60°C/140°F) indicates a problem (e.g., clogged filter, inefficient cooling).

Test the hydraulic pressure regularly to ensure it operates within the manufacturer’s recommended range.

3. Lubrication System

Check lubricating oil levels and quality daily. Oil should be clear (not cloudy or contaminated with metal particles) and free of water.

Replace lubricating oil at the manufacturer’s recommended intervals (typically every 1,000-2,000 operating hours) and change the oil filter simultaneously.

Inspect lubrication lines for clogs or leaks. Ensure oil is reaching all critical components, especially the main bearings.

Monitor oil temperature—abnormal heat may indicate insufficient lubrication or a worn bearing.

Use only the lubricant specified by the crusher manufacturer; using the wrong type can cause component damage.

4. Eccentric Shaft and Bearings

Regularly inspect bearings for noise, vibration, or overheating—these are signs of wear or insufficient lubrication.

Check the eccentric shaft for cracks or deformation during scheduled overhauls.

Ensure the shaft and bearings are properly lubricated at all times.

Replace bearings if they show signs of damage (e.g., pitting, scoring) to avoid catastrophic failure of the eccentric shaft.

5. Drive System (Motor and Gearbox)

Inspect the motor for unusual noise, vibration, or overheating. Check electrical connections for tightness and signs of corrosion.

Examine the coupling (which connects the motor to the gearbox) for wear, misalignment, or damage. Realign if necessary.

Maintain the gearbox by checking oil levels, changing oil at recommended intervals, and inspecting for leaks or gear wear.

Test the motor’s electrical components (e.g., windings, capacitors) periodically to ensure safe and efficient operation.

The Complete Hydraulic Cone Crusher Maintenance Schedule: Daily, Weekly, and Monthly Tasks

Daily Maintenance Tasks (To Be Performed Before and After Operation)

Visual Inspection: Walk around the crusher to check for loose fasteners, damaged guards, leaks (hydraulic or lubrication), and signs of abnormal wear on liners.

Fluid Checks: Verify hydraulic fluid and lubricating oil levels. Check fluid quality for contamination.

Safety Features: Ensure all safety guards are in place and functional. Test emergency stop buttons and alarms.

Crushing Chamber: Inspect liners for wear or damage. Clear any material buildup in the chamber.

Temperature and Vibration: During operation, monitor the crusher for unusual vibration, noise, or overheating of the motor, gearbox, or bearings.

Weekly Maintenance Tasks

Lubrication System: Clean lubrication filters and check for clogs. Inspect lubrication lines for leaks.

Hydraulic System: Check hydraulic hoses and seals for wear. Test the hydraulic pressure and adjust if necessary.

Fasteners: Tighten all critical fasteners (liner bolts, frame bolts, motor mounts) to the manufacturer’s torque specifications.

Discharge Opening: Measure and adjust the discharge opening to ensure it meets production requirements. Misalignment here can cause uneven wear.

Cooling System: Clean the cooling fan and radiator to remove dust and debris, ensuring efficient heat dissipation for hydraulic and lubricating fluids.

Monthly and Quarterly Maintenance Tasks

Oil Changes: Replace hydraulic fluid and lubricating oil (follow manufacturer guidelines for frequency). Change all filters (oil, hydraulic, air).

Bearings and Eccentric Shaft: Inspect bearings for wear using vibration analysis or temperature monitoring. Check the eccentric shaft for alignment and damage.

Gearbox Inspection: Drain and inspect gearbox oil for metal particles (a sign of gear wear). Inspect gears for pitting or scoring if accessible.

Electrical System: Test motor windings for insulation resistance. Inspect wiring for damage and tighten connections.

Liner Replacement: Measure liner wear and replace if necessary. Ensure new liners are properly aligned and fastened.

Annual Overhaul

Disassemble critical components (eccentric shaft, bearings, gearbox) for thorough inspection.

Replace worn components (bearings, seals, gears) even if they show only minor signs of wear.

Reassemble the crusher to manufacturer specifications, ensuring proper alignment and torque.

Calibrate all systems (hydraulic, lubrication, drive) to ensure optimal performance.

Troubleshooting Common Hydraulic Cone Crusher Issues: Quick Fixes from The Complete Guide

1. Excessive Vibration

2. Reduced Crushing Efficiency

3. Hydraulic Fluid Leaks

4. Bearing Overheating

5. Motor Failure

Best Practices to Enhance Maintenance Effectiveness

Follow Manufacturer Guidelines: Every crusher model has unique requirements—always refer to the manufacturer’s manual for maintenance procedures, fluid types, and torque specifications.

Maintain Detailed Records: Document all maintenance tasks, including dates, parts replaced, fluid changes, and issues encountered. This helps identify patterns and plan future maintenance.

Train Operators and Maintenance Staff: Ensure your team understands how to perform basic checks, recognize warning signs, and follow safety protocols. Well-trained staff can prevent accidental damage and catch issues early.

Use Genuine Parts: Replace worn components with genuine manufacturer parts. Generic parts may be cheaper but often lack the quality and fit needed to ensure optimal performance and safety.

Embrace Predictive Maintenance: Use modern tools (e.g., vibration sensors, temperature monitors, oil analysis kits) to predict component failure before it occurs. This shifts maintenance from reactive to proactive.