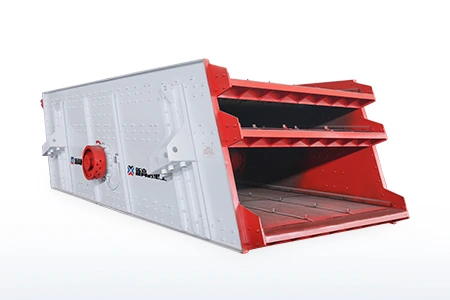

What Is a Single Deck Vibrating Screen? Core Definition & Advantages

Simple structure and compact design, requiring less installation space and lower initial investment.

Easy operation and maintenance—fewer components mean reduced downtime and lower maintenance costs.

High screening efficiency for single-grade requirements—focused vibration energy ensures thorough separation without energy waste on multiple decks.

Flexible screen mesh replacement—adaptable to different material particle size requirements by changing mesh specifications (1–200 mesh).

Durable construction—optimized for heavy-duty operations, with wear-resistant components suitable for abrasive materials like ore and gravel.

Key Components of a Single Deck Vibrating Screen

Vibration Motor: The power source of the screen, typically dual vibration motors installed symmetrically. It generates linear or circular vibration by adjusting the phase angle of the motor eccentric blocks, driving the screen deck to vibrate.

Screen Deck: The single-layer screening surface, usually made of high-strength steel mesh, polyurethane mesh, or rubber mesh. The mesh material and aperture are selected based on the material’s abrasiveness and target particle size.

Screen Frame: The load-bearing structure, constructed from welded steel profiles. It provides stable support for the screen deck and vibration motor, ensuring structural integrity during high-intensity vibration.

Shock Absorbing Springs: Installed between the screen frame and the base. They reduce vibration transmission to the foundation, minimizing noise and extending equipment service life.

Feeding & Discharging Hoppers: The feeding hopper ensures uniform material distribution on the screen deck, avoiding local overload; the discharging hopper separates and collects qualified and oversized materials for subsequent processing.

Sealing Cover: Prevents dust and material spillage during operation, complying with environmental protection regulations and improving workplace safety.

How Does a Single Deck Vibrating Screen Work?

Material Feeding: Bulk materials (e.g., ore, sand, aggregates) are evenly fed onto the single screen deck via a vibrating feeder or belt conveyor. The feeding speed is controlled to ensure the material forms a uniform layer on the deck, avoiding excessive accumulation that would reduce screening efficiency.

Vibration Generation: When the vibration motor is activated, the eccentric blocks at both ends of the motor rotate at high speed, generating exciting force. This force drives the screen deck to vibrate in a linear or circular trajectory (depending on the motor installation angle).

Material Separation: Under the action of vibration, the material layer on the screen deck continuously bounces and moves forward. Materials with particle sizes smaller than the screen mesh aperture pass through the deck (qualified products) and are collected by the lower discharging hopper. Oversized materials (particle size larger than the mesh aperture) remain on the deck, move forward with the vibration, and are discharged from the end of the screen for reprocessing (e.g., re-crushing).

Continuous Operation: The entire process is continuous—raw materials are fed continuously, and qualified/oversized materials are discharged simultaneously, ensuring stable and efficient screening of bulk materials.

Applications of Single Deck Vibrating Screen

Mining Industry: Sieving crushed ore (e.g., iron ore, copper ore, limestone) to separate qualified ore particles from oversized ones, ensuring the ore enters the next processing stage (e.g., flotation, grinding) with the correct particle size.

Sand & Gravel Processing: Classifying natural sand, crushed stone, and aggregates to produce construction-grade sand and gravel (e.g., concrete aggregates, road base materials) that meet particle size standards.

Construction Industry: Sieving construction waste (e.g., crushed concrete, brick debris) to separate reusable aggregates from impurities, supporting construction waste recycling.

Coal Preparation Industry: Preliminary sieving of raw coal to remove large gangue and impurities, improving the quality of coal entering the washing process.

Chemical Industry: Sieving chemical raw materials (e.g., fertilizer, plastic particles) to ensure uniform particle size, optimizing product quality and processing efficiency.

Agricultural Industry: Sieving grain, seeds, and fertilizer to remove debris and unqualified particles, ensuring the purity of agricultural products.

How to Choose the Right Single Deck Vibrating Screen?

Material Characteristics: Consider the material’s particle size range, moisture content, abrasiveness, and bulk density. For abrasive materials (e.g., ore), choose a screen deck made of polyurethane or rubber mesh; for materials with high moisture content, select a screen mesh with larger aperture to avoid clogging.

Production Capacity: Determine the required hourly output (TPH) to select the appropriate screen size (length and width). Larger screen decks have higher capacity—typical single deck vibrating screen capacity ranges from 10 to 500 TPH.

Vibration Type: Linear vibration is suitable for materials requiring uniform forward movement and high screening efficiency (e.g., sand, aggregates); circular vibration is ideal for materials with high moisture content or easy clogging (e.g., sticky ore).

Screen Mesh Specification: Choose the mesh aperture based on the target particle size of the qualified product. Common mesh sizes range from 1mm (fine sieving) to 100mm (coarse sieving).

Working Environment: For outdoor or harsh environments (e.g., high temperature, humidity, dust), select a single deck vibrating screen with corrosion-resistant components (e.g., stainless steel screen frame) and reliable sealing.

Maintenance Tips for Single Deck Vibrating Screen

Daily inspection: Check the vibration motor, screen deck, and shock absorbing springs for looseness, wear, or damage. Tighten loose bolts and replace worn components in a timely manner.

Lubrication maintenance: Regularly add lubricating oil to the vibration motor bearings to reduce friction and prevent overheating. Replace the lubricating oil according to the manufacturer’s recommendations (typically every 3–6 months).

Screen mesh maintenance: Clean the screen mesh regularly to remove clogged materials. Replace the screen mesh when it is worn or damaged to ensure screening accuracy.

Foundation inspection: Check the foundation and anchor bolts for stability. Adjust the shock absorbing springs if there is excessive vibration or noise.

Shutdown maintenance: Conduct comprehensive maintenance (e.g., inspecting the screen frame for deformation, replacing worn seals) during scheduled shutdowns to prevent unexpected failures.