Rotary dryers are essential industrial equipment used to remove moisture from bulk materials—ranging from minerals (sand, ore, limestone) and agricultural products (grain, biomass) to food ingredients and chemicals. Their ability to handle high volumes, adapt to diverse materials, and deliver consistent drying results makes them a staple in mining, construction, food processing, and pharmaceutical industries.

Key Components of a Rotary Dryer (Foundation for Understanding How It Works)

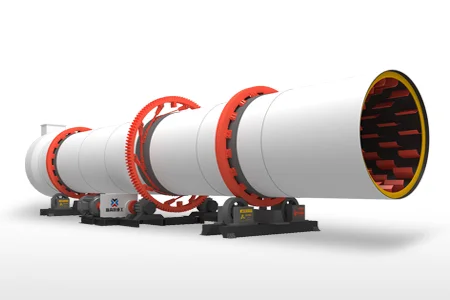

Rotating Drum: The core component—a long, cylindrical shell (typically 3–20m in length, 1–3m in diameter) made of high-grade steel or stainless steel. It’s slightly inclined (1–5°) to enable material movement via gravity as it rotates.

Driving System: Consists of a motor, gearbox, and chain/belt drive that rotates the drum at a slow speed (3–20 RPM). The speed is adjustable to control material residence time (the duration materials stay in the drum for drying).

Heating Source: Provides hot air for moisture evaporation. Common sources include natural gas, propane, diesel burners, steam coils, or waste heat from other industrial processes. The choice depends on material type and temperature requirements (80–800°C).

Feeding & Discharging Systems: A feeder (vibrating feeder, screw feeder) uniformly introduces wet materials into the drum’s inlet end; a discharge chute or conveyor removes dried materials from the outlet end.

Airflow System: Includes fans, ductwork, and a cyclone/dust collector. It circulates hot air through the drum and removes moisture-laden exhaust air, preventing dust pollution and ensuring efficient heat transfer.

Lifting Flights: Internal fins (attached to the drum’s inner wall) that lift and tumble materials as the drum rotates. This maximizes material exposure to hot air, enhancing drying efficiency.

How Does a Rotary Dryer Work? Step-by-Step Mechanism

1. Feeding Wet Materials

2. Hot Air Introduction & Circulation

Co-Current Flow: Hot air and materials move in the same direction (both entering from the inlet end, exiting from the outlet end). Ideal for heat-sensitive materials (e.g., food, pharmaceuticals) as the hottest air meets the wettest materials, reducing thermal damage.

Counter-Current Flow: Hot air flows opposite to material movement (hot air enters from the outlet end, exits from the inlet end). The hottest air meets nearly dry materials, maximizing heat efficiency—perfect for high-moisture, non-heat-sensitive materials (e.g., ore, sand).

3. Tumbling & Heat Transfer (Core Drying Stage)

4. Moisture Removal & Exhaust Treatment

5. Discharging Dried Materials

How Does a Rotary Dryer Work for Different Material Types? (Key Variations)

Minerals & Aggregates (Sand, Ore): Use high-temperature heating sources (500–800°C) and counter-current airflow for maximum efficiency. Lifting flights are designed to handle abrasive materials, with wear-resistant drum liners.

Food & Pharmaceuticals: Use low-temperature (80–150°C) hot air and co-current airflow to avoid thermal damage. The drum and components are made of food-grade stainless steel (304/316) to meet hygiene standards.

Biomass & Agricultural Products (Grain, Wood Chips): Require moderate temperatures (100–200°C) and gentle tumbling to prevent material breakage. Some models include steam jackets for indirect heating (avoiding direct contact with hot air).

Chemicals: May use indirect heating (via steam coils) if the material is flammable or toxic, preventing direct contact between the material and open flames. Temperature and residence time are tightly controlled to avoid chemical reactions.

Key Factors That Affect How a Rotary Dryer Works (Efficiency & Performance)

Material Moisture Content: Higher initial moisture requires longer residence time or higher temperatures.

Drum Rotation Speed: Faster speeds reduce residence time (risk of under-drying); slower speeds increase residence time (risk of over-drying).

Hot Air Temperature & Flow Rate: Higher temperatures (within material limits) and faster airflow speed up drying, but excessive heat can damage heat-sensitive materials.

Drum Incline Angle: Steeper angles (up to 5°) speed up material movement (shorter residence time); shallower angles slow movement (longer residence time).

Lifting Flight Design: Optimized flight geometry ensures maximum material-air contact—critical for uniform drying.