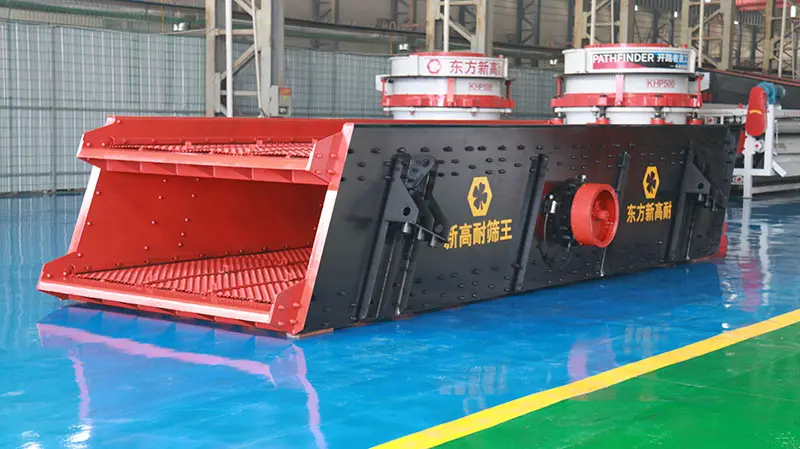

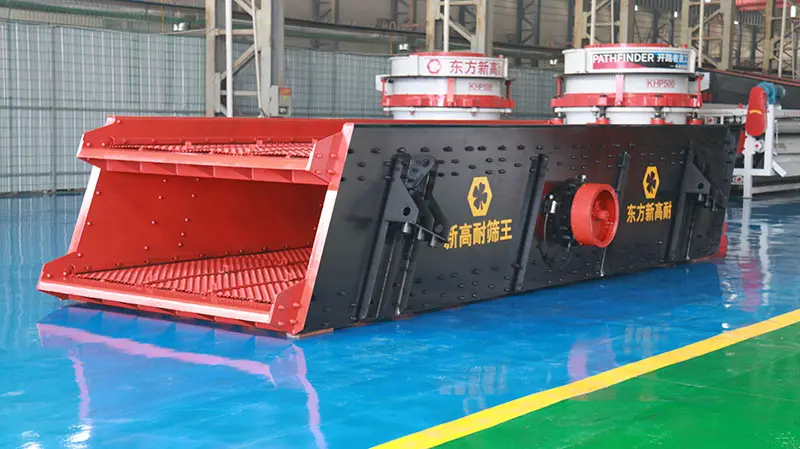

In mining, aggregate, and mineral processing industries, a reliable mining

vibrating screen is critical for separating materials by particle size, ensuring downstream crushing and grinding efficiency. The Mining Vibrating Screen stands out as a high-performance solution, engineered with advanced technology to deliver stable operation, high screening efficiency, and long service life. Below is a comprehensive overview of its core features, application scenarios, operational tips, and maintenance practices—helping you maximize the value of this essential mining vibrating screen.

Core Features of Mining Vibrating Screen

The mining vibrating screen is designed to address the harsh conditions of mining operations, combining robust construction with intelligent design. Key advantages that make it a top choice for mining vibrating screen users include:

1. Durable Structural Design for Harsh Mining Environments

Built with a heavy-duty steel frame and reinforced side plates, the mining vibrating screen resists deformation and vibration fatigue even under continuous high-load operation. The screen box adopts a modular design, reducing assembly time and simplifying maintenance. Additionally, the anti-corrosion coating (epoxy primer + topcoat) protects the equipment from moisture, dust, and abrasive materials—extending the mining vibrating screen’s service life by 30% compared to ordinary models.

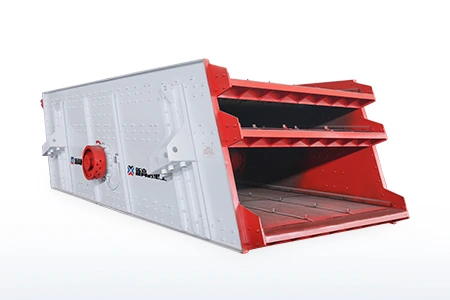

2. High Screening Efficiency & Large Processing Capacity

Equipped with a dual-vibration motor drive system, the mining vibrating screen generates linear vibration with adjustable frequency (1200-1500 rpm) and amplitude (4-8 mm). This design ensures materials move evenly across the screen surface, minimizing blockages and maximizing screening efficiency (up to 95%). The mining vibrating screen covers a wide processing capacity range (50-1200 t/h), with screen sizes ranging from 1.2×4.8m to 2.4×7.5m—suitable for both small-scale mines and large aggregate plants.

3. Versatile Screen Mesh Options for Multi-Material Screening

The mining

vibrating screen supports multiple screen mesh types (steel wire mesh, polyurethane mesh, perforated steel plate) to adapt to different materials and screening requirements. For abrasive ores (e.g., granite, basalt), polyurethane mesh offers 2-3 times longer wear resistance than traditional steel mesh. For fine-grained materials (e.g., sand, coal), high-precision steel wire mesh ensures accurate particle classification, with screening accuracy up to 98%.

4. Intelligent & User-Friendly Operation

Integrated with a digital control system, the mining vibrating screen allows operators to adjust vibration parameters (frequency, amplitude) remotely, adapting to real-time material changes without shutdown. The system also features fault alarm functions (e.g., motor overheating, screen mesh damage) to alert staff promptly—reducing unplanned downtime. Additionally, the low-noise design (≤85 dB) improves working conditions, complying with industrial environmental standards.

5. Easy Maintenance & Low Operational Costs

The mining vibrating screen simplifies maintenance with quick-access doors and detachable screen mesh frames—screen mesh replacement can be completed in 1-2 hours, 50% faster than conventional mining vibrating screens. The dual-vibration motors are equipped with protective covers and require minimal lubrication (only once every 100 operating hours), lowering long-term maintenance costs.

Applications of Mining Vibrating Screen

With its versatility and reliability, the mining vibrating screen is widely used in various mining and industrial scenarios:

Ore Processing: Screening iron ore, copper ore, gold ore, and other metallic ores during crushing and beneficiation processes.

Aggregate Production: Classifying crushed stone, gravel, and sand for construction projects (highways, bridges, buildings).

Coal Mining: Separating coal from gangue and classifying coal particles by size for power plants and coking plants.

Non-Metallic Mineral Processing: Screening limestone, gypsum, quartz sand, and other non-metallic minerals for building materials, chemical, and glass industries.

Waste Recycling: Sorting construction waste (concrete, bricks) for reuse as recycled aggregates.

Operational Tips for Mining Vibrating Screen

To ensure optimal performance and extend the service life of your mining vibrating screen, follow these operational best practices:

Pre-Operation Inspection: Check the screen mesh tension, motor connections, and lubrication levels before startup. Ensure no foreign objects (e.g., metal debris) are in the screen box.

Uniform Feeding: Use a vibrating feeder to distribute materials evenly across the screen surface—avoid overloading one side, which can cause uneven wear and reduce screening efficiency.

Adjust Parameters Based on Materials: For high-moisture materials, increase vibration amplitude to prevent clogging; for fine materials, reduce frequency to improve separation accuracy.

Avoid Overload Operation: Operate within the rated capacity (50-1200 t/h) to prevent motor burnout and structural damage.

Maintenance Guide for Mining Vibrating Screen

Regular maintenance is key to keeping the mining

vibrating screen running smoothly. Implement this maintenance schedule:

Daily Maintenance: Clean the screen surface and frame to remove material buildup; check for loose bolts and tighten if necessary.

Weekly Maintenance: Inspect screen mesh for wear, holes, or loosening—replace damaged mesh immediately. Check vibration motor bearings for overheating (normal temperature ≤70℃).

Monthly Maintenance: Lubricate motor bearings and connecting shafts with lithium-based grease; inspect the steel frame for corrosion or deformation.

Quarterly Maintenance: Disassemble the screen box to clean internal components; check the tension of vibration springs and replace worn springs.

Annual Maintenance: Conduct a comprehensive inspection of the entire system, including motors, control panels, and structural components; replace aging parts (e.g., seals, cables) to prevent failures.