A cone crusher is a heavy-duty industrial equipment designed for secondary or tertiary crushing of hard, abrasive materials like granite, basalt, and iron ore. It is widely used in mining, quarrying, and construction aggregate production lines for reducing large rocks into uniform coarse or fine aggregates.

Unlike jaw crushers that use compressive force with a fixed and movable jaw, a cone crusher operates via a rotating eccentric shaft that drives a crushing cone, delivering consistent and high-efficiency crushing performance.

Core Working Mechanism: How a Cone Crusher Works

The working principle of a cone crusher revolves around controlled compressive force, generated by the interaction between a fixed cone (bowl liner) and a movable cone (mantle). The entire process unfolds in three key stages:

1. Material Feeding Stage

Raw materials (pre-crushed by a primary crusher to 100-300mm) are fed into the cone crusher’s hopper. The hopper guides materials into the crushing chamber, which is formed between the fixed bowl liner and the movable mantle.

A rotating distributor plate ensures uniform material feeding, preventing overloading and ensuring consistent crushing pressure across the chamber.

2. Crushing Stage (Compressive Force Action)

The cone crusher’s eccentric shaft is driven by a motor and reducer, causing the movable mantle to rotate in an eccentric path. As the mantle moves closer to the fixed bowl liner, it exerts strong compressive force on the materials trapped between them.

Hard rocks are crushed or fractured under this pressure until they reach the size of the discharge opening. The eccentric rotation creates a continuous crushing cycle, as the mantle alternately closes in on and pulls away from the bowl liner.

3. Discharge Stage

Once materials are crushed to the desired size, they fall through the adjustable discharge opening at the bottom of the crushing chamber. The discharge size can be fine-tuned by adjusting the gap between the mantle and the bowl liner, adapting to different aggregate requirements.

Uncrushed oversized materials remain in the chamber to undergo repeated compressive force until they meet the discharge specifications.

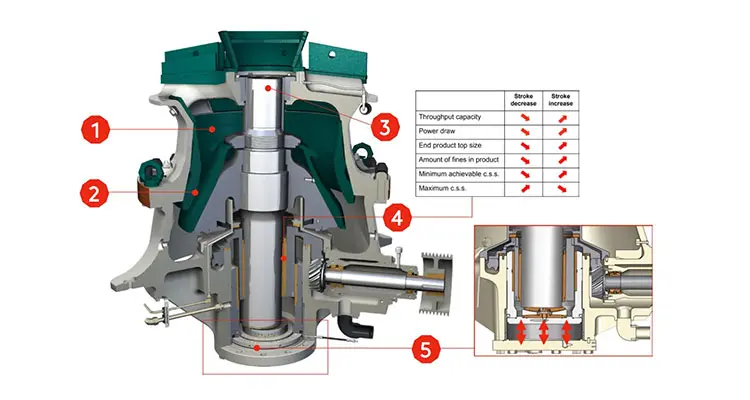

Key Components That Power a Cone Crusher

A cone crusher’s reliable operation depends on well-integrated core components, each playing a critical role in its working mechanism:

1. Fixed Cone (Bowl Liner)

The fixed cone is a stationary component lined with a wear-resistant bowl liner (made of high-manganese steel or alloy). It forms the outer wall of the crushing chamber and withstands the impact of compressive force.

2. Movable Cone (Mantle)

The movable cone is the rotating component lined with a mantle, paired with the bowl liner to deliver crushing force. Its eccentric movement is the core of the cone crusher’s working principle.

3. Eccentric Shaft

This shaft drives the movable cone’s eccentric rotation. It is connected to the motor via a pulley or gear drive, converting rotational energy into the compressive force needed for crushing.

4. Drive System

Composed of a motor, reducer, and transmission parts (gears or belts), it provides stable power to the eccentric shaft. The system ensures the cone crusher operates at a constant speed (typically 100-300 RPM) for optimal efficiency.

5. Discharge Adjustment Device

This component allows operators to adjust the discharge gap, controlling the size of the final aggregate. It ensures the cone crusher adapts to different production needs, from coarse to fine crushing.

6. Hydraulic Protection System

Modern cone crushers are equipped with a hydraulic system to protect against overloads. If uncrushable materials (e.g., metal) enter the chamber, the system retracts the mantle to release the material, preventing component damage.

Factors That Affect a Cone Crusher’s Working Efficiency

Several key factors influence how effectively a cone crusher works, directly impacting production capacity and aggregate quality:

1. Discharge Gap Size

A smaller gap produces finer aggregates but reduces throughput, while a larger gap increases capacity but yields coarser materials. It must be adjusted based on production requirements.

2. Rotation Speed

Optimal speed ensures materials are crushed efficiently without excessive wear. Too high a speed causes material bouncing, while too low a speed reduces crushing frequency.

3. Material Properties

Hardness, density, and moisture content of raw materials affect crushing efficiency. Wet or sticky materials may clog the chamber, while extremely hard materials increase wear on liners.

4. Feeding Uniformity

Uneven feeding leads to inconsistent crushing pressure and reduced capacity. A uniform feed rate ensures the crushing chamber is fully utilized and aggregate quality is stable.

Industrial Applications of Cone Crushers

Thanks to its efficient working mechanism and ability to handle hard materials, a cone crusher is indispensable in various industries:

1. Mining Industry

Used for secondary crushing of ore (iron ore, copper ore, gold ore) to improve mineral beneficiation efficiency. It produces uniform ore particles for subsequent processing.

2. Aggregate Production

Crushes hard rocks into high-quality aggregates for concrete, asphalt, and road construction. The adjustable discharge gap meets strict aggregate gradation standards.

3. Construction & Demolition

Processes construction waste (concrete, bricks) into recycled aggregates, supporting sustainable building practices. Its robust design handles abrasive waste materials.

4. Quarrying

Reduces large quarried rocks (granite, limestone) into usable materials for landscaping, building facades, and infrastructure projects.

Conclusion

A cone crusher works by leveraging eccentric rotation to generate compressive force between a fixed cone and movable cone, delivering efficient secondary and tertiary crushing of hard materials. Its step-by-step mechanism ensures consistent aggregate quality and high throughput.

Understanding how a cone crusher works—along with its core components and influencing factors—helps operators optimize performance, reduce wear, and maximize production efficiency. It remains a cornerstone of modern mining and construction aggregate lines.