A flotation machine (also called a flotation cell) is a key mineral processing equipment used to separate useful minerals from gangue. It leverages the difference in surface wettability between minerals to achieve separation, widely applied in mining of copper, lead, zinc, gold, and non-metallic minerals.

The working principle of a flotation machine revolves around generating mineralized bubbles that carry useful minerals to the surface, while gangue sinks to the bottom for separation.

Core Working Mechanism: How a Flotation Machine Works

The operation of a flotation machine involves five sequential stages, each critical to effective mineral separation. The entire process relies on the interaction of ore slurry, reagents, and air bubbles.

1. Ore Slurry Feeding

Crushed and ground ore is mixed with water to form ore slurry (solid-liquid mixture), which is fed into the flotation machine’s cell. The slurry concentration is controlled at 20-40% to ensure optimal reagent reaction and bubble attachment.

A steady feed rate prevents overloading the cell, maintaining stable separation conditions throughout the process.

2. Reagent Addition & Mixing

Specialized flotation reagents are added to the slurry to modify the surface properties of minerals. Common reagents include collectors, frothers, modifiers, and depressants, each serving a specific role.

Collectors make useful minerals hydrophobic (water-repellent), while frothers stabilize air bubbles; modifiers adjust the slurry’s pH to enhance reagent effectiveness.

3. Air Bubble Generation

Air is introduced into the flotation machine via a rotor-impeller system or air sparger. The rotating impeller creates negative pressure, drawing air into the slurry and breaking it into fine, uniform bubbles (0.1-1mm in diameter).

The size of bubbles is critical—smaller bubbles increase the contact area with minerals, improving separation efficiency.

4. Mineral Attachment to Bubbles

Hydrophobic useful minerals (treated by collectors) adhere to the surface of air bubbles as they rise through the slurry. Hydrophilic gangue minerals, by contrast, remain in the slurry and do not attach to bubbles.

The impeller’s stirring action ensures thorough contact between bubbles and mineral particles, maximizing the attachment rate.

5. Separation & Discharge

Mineralized bubbles (minerals + bubbles) rise to the surface of the slurry, forming a stable froth layer. This froth—containing useful minerals—is scraped off by a rotating froth paddle into a collection trough.

Gangue minerals sink to the bottom of the cell and are discharged as tailings, completing the separation cycle.

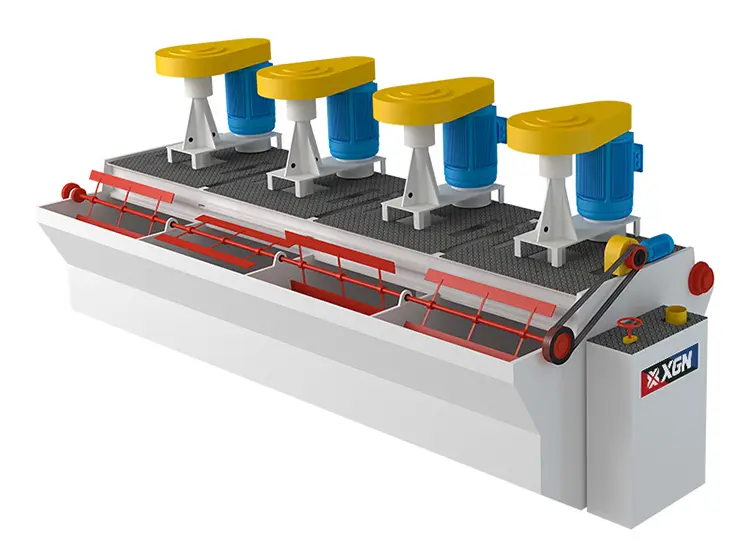

Key Components of a Flotation Machine

A flotation machine’s reliable operation depends on well-integrated core components, each supporting its working principle:

1. Flotation Cell (Tank)

The main chamber where slurry, reagents, and air interact. It is designed with a baffle to prevent froth from mixing back into the slurry and ensure smooth separation.

2. Rotor-Impeller System

The core component for bubble generation and stirring. It draws air into the slurry, breaks it into fine bubbles, and agitates the mixture to promote mineral-bubble contact.

3. Air Supply System

Includes an air compressor and pipeline, delivering a continuous, adjustable air flow to the impeller. Stable air supply ensures consistent bubble size and distribution.

4. Reagent Dosing System

Controls the amount and timing of reagent addition. Precision dosing is essential to avoid reagent waste and ensure optimal mineral surface modification.

5. Froth Paddle (Scraper)

A rotating paddle that gently scrapes the froth layer from the slurry surface. Its speed is adjustable to match froth generation rate, preventing froth accumulation.

Factors Affecting Flotation Machine Performance

Several key factors influence how effectively a flotation machine works, directly impacting separation efficiency and mineral recovery rate:

1. Slurry pH Value

pH affects reagent activity and mineral surface wettability. Most flotation processes require a pH of 8-12, adjusted by modifiers like lime or sulfuric acid.

2. Bubble Size & Air Flow

Fine bubbles (0.1-0.5mm) improve mineral attachment, while excessive air flow causes bubble coalescence and reduces separation precision.

3. Reagent Dosage & Type

Insufficient collector dosage reduces mineral hydrophobicity; excessive dosage increases costs and causes gangue entrainment. The right reagent type matches specific mineral properties.

4. Slurry Concentration & Temperature

Optimal concentration (20-40%) balances mineral contact and fluidity. Higher temperatures accelerate reagent reactions but may destabilize froth.

Industrial Applications of Flotation Machines

Flotation machines are indispensable in mineral processing and related industries, thanks to their efficient separation mechanism:

1. Mining Industry

Used for beneficiation of non-ferrous metals (copper, lead, zinc), precious metals (gold, silver), and ferrous metals (iron ore). It improves ore grade and mineral recovery rate.

2. Non-Metallic Mineral Processing

Separates coal, fluorite, talc, and graphite from gangue, meeting quality standards for industrial use and further processing.

3. Environmental Protection

Treats industrial wastewater and sludge, removing hydrophobic pollutants (oils, organic matter) by flotation separation.

Conclusion

A flotation machine works by leveraging mineral surface wettability differences, using reagents and air bubbles to separate useful minerals from gangue. Its step-by-step mechanism ensures efficient, targeted separation for diverse industrial needs.

Understanding how a flotation machine works—along with its components and influencing factors—helps optimize mineral processing workflows, maximize recovery rates, and reduce operational costs.