In industries such as mining, construction, aggregates, and recycling, the performance of your vibrating screen directly impacts production efficiency, product quality, and overall operational costs. Choosing the right vibrating screen supplier is therefore not just a purchasing decision—it’s a strategic investment in your business’s productivity and reliability. With countless suppliers in the market, distinguishing between those that offer subpar products and those that deliver high-quality, tailored solutions can be challenging. This guide breaks down the essential factors to consider when selecting a vibrating screen supplier, ensuring you partner with a provider that meets your unique operational needs.

Why the Right Vibrating Screen Supplier Matters

Before diving into selection criteria, it’s critical to understand the long-term impact of your vibrating screen supplier choice. A reputable supplier does more than just sell you equipment—they act as a partner invested in your success. Poorly manufactured vibrating screens from an unreliable supplier can lead to frequent breakdowns, costly downtime, and inconsistent material separation, all of which harm your bottom line. On the other hand, a trusted vibrating screen supplier delivers durable, efficient equipment that aligns with your workflow, provides timely support, and offers solutions to optimize your screening processes. Additionally, the right supplier can adapt to your growing needs, whether that means scaling up equipment capacity or customizing screens for specialized applications.

Core Criteria for Selecting a Vibrating Screen Supplier

When evaluating potential vibrating screen suppliers, focus on the following key factors to ensure you make an informed decision:

1. Industry Experience and Expertise

Experience is a hallmark of a reliable vibrating screen supplier. Look for providers with a proven track record in your specific industry—whether it’s mining, construction, or recycling. An experienced supplier understands the unique challenges of your sector, from harsh operating environments to strict material separation requirements. They can offer insights into which screen types (e.g., circular vibrating screens, linear vibrating screens, high-frequency screens) best suit your applications and provide case studies or references from similar clients. Avoid suppliers with limited industry experience, as they may not anticipate potential issues or deliver equipment that fails to meet your operational demands.

2. Product Quality and Manufacturing Standards

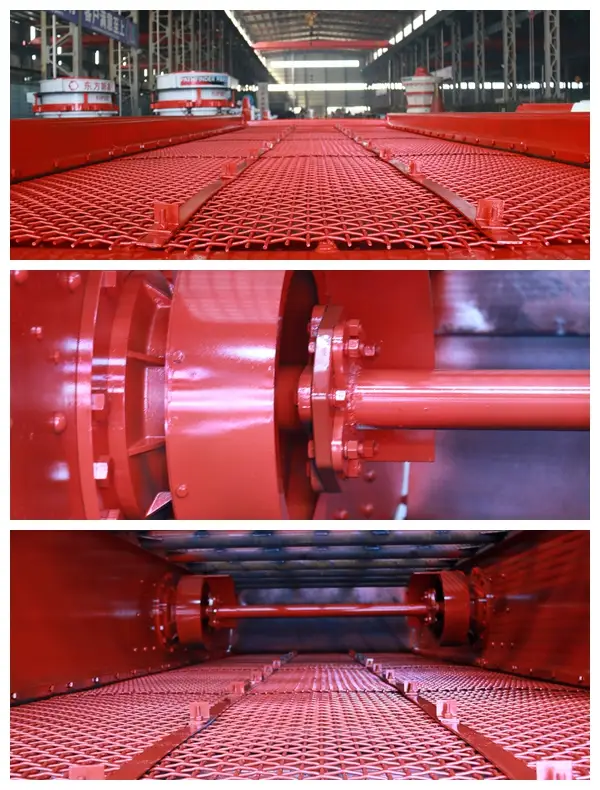

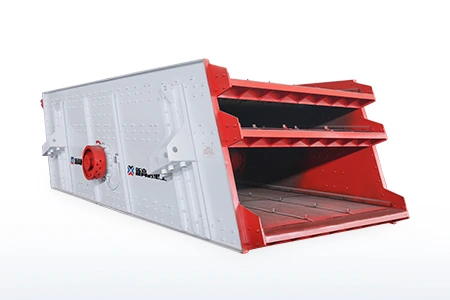

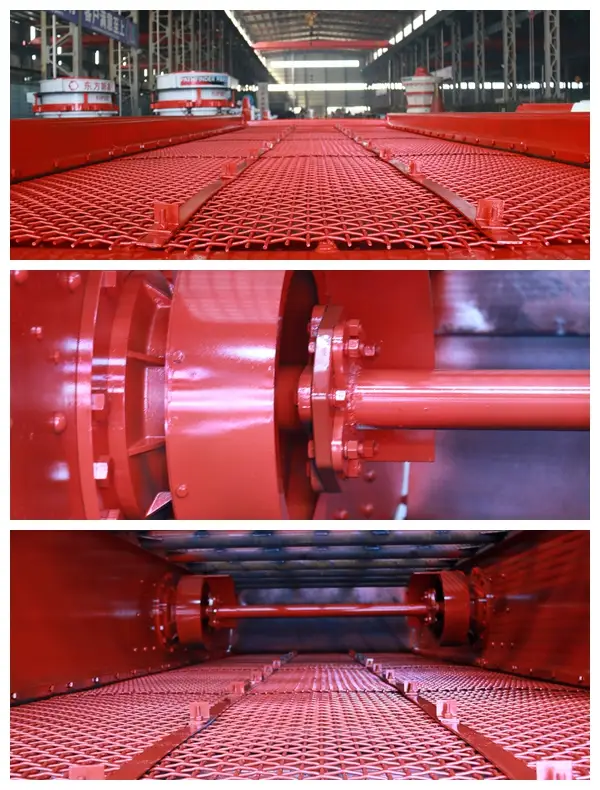

The quality of the

vibrating screen directly affects its performance and lifespan. A reputable vibrating screen supplier adheres to strict manufacturing standards and uses high-grade materials. Inquire about their production processes, quality control measures, and certifications (such as ISO 9001 for quality management). Ask about the components they use—for example, durable bearings, corrosion-resistant frames, and high-tensile screen meshes. Reputable suppliers will be transparent about their manufacturing practices and may even offer factory tours or product samples to demonstrate quality. Additionally, check if their screens undergo rigorous testing (e.g., load testing, vibration testing) to ensure they can withstand heavy-duty use.

3. Customization Capabilities

No two industrial operations are identical, so a one-size-fits-all vibrating screen may not meet your specific needs. A top-tier vibrating screen supplier offers customization options to tailor equipment to your unique requirements. This could include adjusting screen size, capacity, vibration frequency, or mesh type to match your material characteristics (e.g., wet vs. dry, fine vs. coarse) and production targets. For example, if you’re screening abrasive mining materials, the supplier should be able to recommend and manufacture screens with reinforced frames and wear-resistant components. Ask about their design process—do they work with your team to assess your needs, or do they offer prefabricated solutions only? Suppliers with in-house engineering teams are more likely to deliver effective custom solutions.

4. After-Sales Support and Service

A vibrating screen is a long-term investment, and ongoing support from your supplier is essential for minimizing downtime and maximizing equipment lifespan. When evaluating a vibrating screen supplier, ask about their after-sales services, including technical support, maintenance, and replacement parts availability. Do they offer on-site installation and training for your team? Can they provide quick access to critical parts (e.g., screen meshes, bearings) to avoid prolonged downtime? Look for suppliers with a dedicated customer support team and a network of service technicians, especially if your operation is in a remote location. Additionally, inquire about warranty terms—reputable suppliers stand behind their products with comprehensive warranties that cover defects and performance issues.

5. Pricing and Value

While cost is an important factor, it should not be the sole determinant when choosing a vibrating screen supplier. Opting for the cheapest option may save money upfront but can lead to higher costs in the long run due to frequent repairs, downtime, and premature equipment replacement. Instead, focus on value—consider the total cost of ownership, which includes the initial purchase price, maintenance costs, energy efficiency, and lifespan. A high-quality vibrating screen from a trusted supplier may have a higher upfront cost but will deliver better performance, lower maintenance expenses, and a longer service life, providing greater value over time. Ask suppliers for detailed quotes that break down costs and compare them based on the criteria outlined above (quality, customization, support) rather than just price alone.

6. Reputation and Customer Reviews

A

vibrating screen supplier’s reputation is a reflection of their past performance and customer satisfaction. Take the time to research their reputation by reading customer reviews, testimonials, and industry ratings. Look for reviews on third-party platforms, industry forums, or the supplier’s website. Pay attention to feedback about product quality, delivery times, communication, and after-sales support. Additionally, ask the supplier for references from current or past clients—contact these references to learn about their experiences working with the supplier. A supplier with a strong reputation for reliability and customer service is more likely to deliver on their promises.

How to Evaluate and Compare Vibrating Screen Suppliers

Once you’ve identified potential vibrating screen suppliers, use the following steps to evaluate and compare them effectively:

Define Your Requirements: Clearly outline your operational needs, including material type, screening capacity, desired efficiency, and any customization requirements. This will help you communicate your needs to suppliers and assess if they can meet them.

Request Detailed Proposals: Ask each supplier to provide a detailed proposal that includes product specifications, customization options, pricing, delivery timelines, warranty terms, and after-sales services. Ensure the proposal addresses all your requirements.

Conduct Interviews or Site Visits: Schedule meetings with key representatives from each supplier to discuss your needs and ask questions. If possible, visit their manufacturing facility to assess quality control processes and production capabilities.

Check References and Reviews: As mentioned earlier, verify the supplier’s reputation through customer references and reviews.

Evaluate Total Value: Compare suppliers based on the criteria outlined (experience, quality, customization, support) and calculate the total cost of ownership to determine which offers the best value.

The Benefits of Partnering with a Leading Vibrating Screen Supplier

Partnering with a top-tier vibrating screen supplier offers numerous benefits for your business, including:

Enhanced Productivity: High-quality, efficient vibrating screens reduce downtime and improve material separation, boosting overall production output.

Cost Savings: Durable equipment and reliable after-sales support minimize maintenance costs, repair expenses, and the need for premature replacement.

Customized Solutions: Equipment tailored to your needs ensures optimal performance for your specific applications.

Peace of Mind: A trusted supplier provides ongoing support, so you can focus on your core operations without worrying about equipment issues.

Scalability: Leading suppliers can adapt to your growing business needs, whether you need to expand capacity or add new screening processes.

Conclusion: Choose Wisely for Long-Term Success

Selecting the right

vibrating screen supplier is a critical decision that impacts your business’s productivity, efficiency, and profitability. By focusing on industry experience, product quality, customization capabilities, after-sales support, value, and reputation, you can identify a supplier that acts as a true partner in your success. Avoid cutting corners on quality or support—invest in a reputable vibrating screen supplier, and you’ll reap the benefits of reliable equipment, minimized downtime, and optimized screening processes for years to come.