1. Design & Structural Differences

Gyratory Crusher

Core Structure: Features a large, fixed outer shell (concave) and a rotating inner cone (mantle) mounted on a vertical shaft. The shaft is inclined at a 15-20° angle, and the cone rotates eccentrically around the vertical axis.

Feed Opening: Has a large, circular feed opening (typically 300-1500mm) designed to accept large, uncrushed raw materials (up to 1.5m in diameter).

Size & Weight: Bulky and heavy-duty, with a tall, cylindrical profile. Industrial models can weigh hundreds of tons, requiring permanent installation in fixed crushing plants.

Key Component: Equipped with a heavy-duty mainframe and a spider bearing assembly that supports the rotating shaft, ensuring stability during high-load operation.

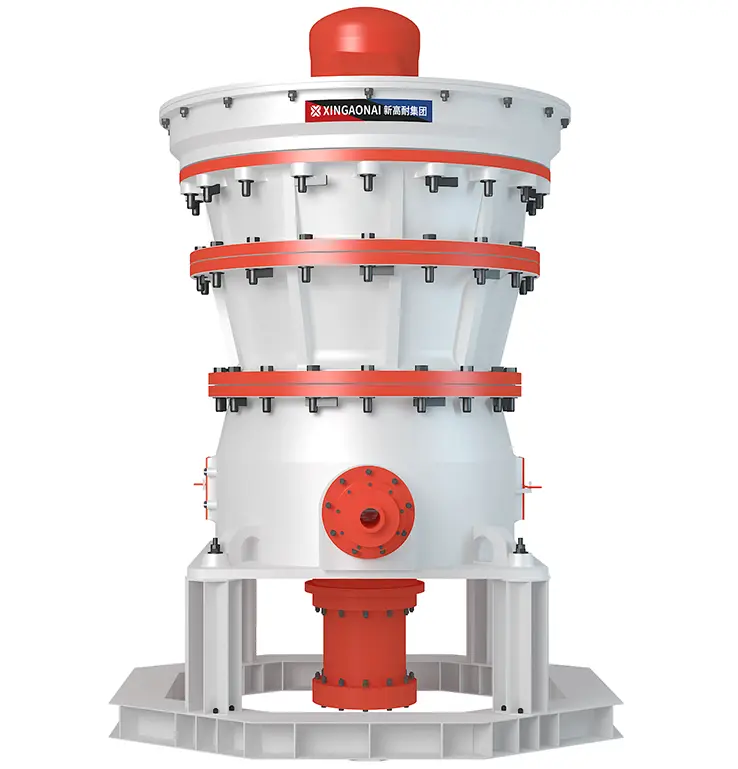

Cone Crusher

Core Structure: Consists of a smaller, vertical outer shell and a rotating inner cone. The shaft is vertical, and the cone rotates with a smaller eccentricity (5-10°) compared to gyratory crushers.

Feed Opening: Smaller feed opening (typically 50-300mm) designed for secondary or tertiary crushing of pre-crushed materials.

Size & Weight: More compact and lightweight than gyratory crushers, making them suitable for both fixed plants and mobile crushing units.

Key Component: Features a hydraulic or mechanical adjustment system for gap control between the cone and concave, allowing precise control of output particle size.

2. Working Principle Differences

Gyratory Crusher

Crushing Action: The inclined rotating cone creates a continuous crushing zone between the mantle and concave. Raw materials are fed from the top, and as the cone rotates, they are gradually compressed and crushed between the two surfaces.

Crushing Process: Utilizes a "compression crushing" principle, with materials moving downward through the crushing zone in a spiral path. The continuous rotation ensures a steady, high-volume crushing process.

Speed: Operates at a lower rotational speed (80-150 RPM) compared to cone crushers, focusing on high torque for breaking large, hard materials.

Cone Crusher

Crushing Action: The vertical cone rotates eccentrically, creating intermittent compression between the mantle and concave. Materials are crushed in a series of short, intense impacts as the cone moves closer to the concave.

Crushing Process: Combines compression and impact crushing, with materials being crushed multiple times as they pass through the crushing chamber. The smaller eccentricity results in a more uniform particle size.

Speed: Operates at a higher rotational speed (150-300 RPM), enhancing crushing efficiency for medium to fine crushing tasks.

3. Performance & Capacity Differences

Gyratory Crusher

Capacity: High production capacity (500-10,000 t/h), making it ideal for large-scale mining and primary crushing operations. It can handle massive volumes of raw materials without frequent downtime.

Output Size: Produces coarse to medium-sized aggregates (20-100mm). It is not designed for fine crushing, as the crushing process is less precise.

Energy Efficiency: More energy-efficient for primary crushing of large materials, as the continuous crushing action minimizes energy waste.

Cone Crusher

Capacity: Lower capacity (50-1,500 t/h) compared to gyratory crushers, suited for secondary, tertiary, or quaternary crushing.

Output Size: Produces fine to medium-sized aggregates (5-40mm) with uniform particle size distribution. It is ideal for producing high-quality sand and gravel for construction projects.

Energy Efficiency: More energy-efficient for fine crushing, as the higher rotational speed and impact crushing action reduce the need for multiple crushing stages.

4. Application Differences

Gyratory Crusher

Primary Application: Used for primary crushing of large, hard raw materials in mining (iron ore, copper ore, granite) and aggregate production. It is the first stage in a multi-stage crushing process.

Ideal Projects: Large-scale mining operations, quarries producing coarse aggregates, and infrastructure projects requiring high-volume primary crushing (e.g., dams, highways).

Material Suitability: Excels at crushing hard, abrasive materials with high compressive strength (≥200 MPa).

Cone Crusher

Primary Application: Used for secondary, tertiary, or quaternary crushing of pre-crushed materials. It is often used after a gyratory or jaw crusher to refine the particle size.

Ideal Projects: Construction projects (high-rise buildings, bridges), concrete production, and sand making. It is also suitable for mobile crushing units used in road construction and demolition waste recycling.

Material Suitability: Suitable for crushing medium to hard materials (compressive strength ≤300 MPa), including limestone, river pebbles, and ore tailings.

5. Maintenance & Operational Differences

Gyratory Crusher

Maintenance: Requires less frequent maintenance due to its robust design and fewer moving parts. However, maintenance tasks (e.g., replacing the mantle and concave) are more complex and time-consuming, often requiring heavy machinery.

Operational Complexity: Simple to operate, with minimal adjustments needed during operation. It is designed for continuous, long-term use in harsh mining environments.

Cone Crusher

Maintenance: Requires more frequent maintenance (e.g., replacing wear parts, adjusting the hydraulic system) due to the higher rotational speed and intense crushing action. However, maintenance tasks are more accessible and can be completed quickly.

Operational Complexity: More complex to operate, as operators need to adjust the crushing gap and monitor the hydraulic system to ensure optimal performance. It offers greater flexibility in adjusting output size.