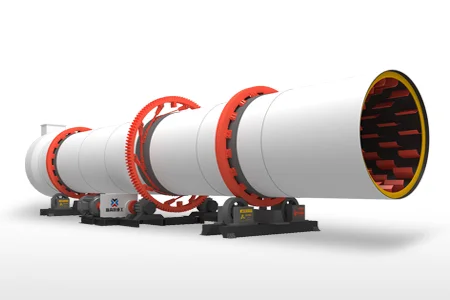

Why Rotary Dryer Maintenance Is Critical for Industrial Operations

Extended Equipment Lifespan: Regular upkeep reduces wear on critical parts (bearings, rollers, gears) by 30-50%, extending the dryer’s service life beyond manufacturer projections.

Optimized Energy Efficiency: Clean heat exchangers, properly lubricated components, and aligned drums improve heat transfer, cutting fuel or electricity consumption by 10-15%.

Minimized Downtime: Proactive inspections catch minor issues (loose fasteners, worn seals) before they escalate into major failures, reducing unplanned downtime by up to 60%.

Enhanced Safety & Compliance: Routine checks on temperature sensors, emergency stops, and exhaust systems ensure adherence to industrial safety standards, mitigating fire or mechanical hazards.

Daily Rotary Dryer Maintenance Checklist

- Pre-Operation Inspections:

Examine the dryer shell for cracks, dents, or corrosion.

Verify roller and tire alignment to ensure smooth drum rotation (no wobbling or scraping).

Check all bolts, nuts, and fasteners for tightness—loose components can cause vibration damage.

Confirm lubrication levels in bearings, gears, and drive chains meet manufacturer specifications.

- In-Operation Monitoring:

Track operating temperatures to ensure they stay within recommended ranges.

Listen for unusual noises (grinding, squeaking, or thudding) that signal worn parts.

Inspect seals and gaskets for air or material leaks, which waste energy and reduce efficiency.

Ensure consistent material feed rates to avoid overloading the dryer.

- Post-Operation Tasks:

Clean the dryer shell and heat exchanger to remove material buildup (buildup inhibits heat transfer).

Empty and clean the dust collection system to maintain airflow.

Inspect the drive system (motor, reducer, belts) for wear or damage.

Document maintenance findings in a log to track equipment performance over time.

Scheduled Rotary Dryer Maintenance (Weekly/Monthly/Quarterly)

Weekly Maintenance

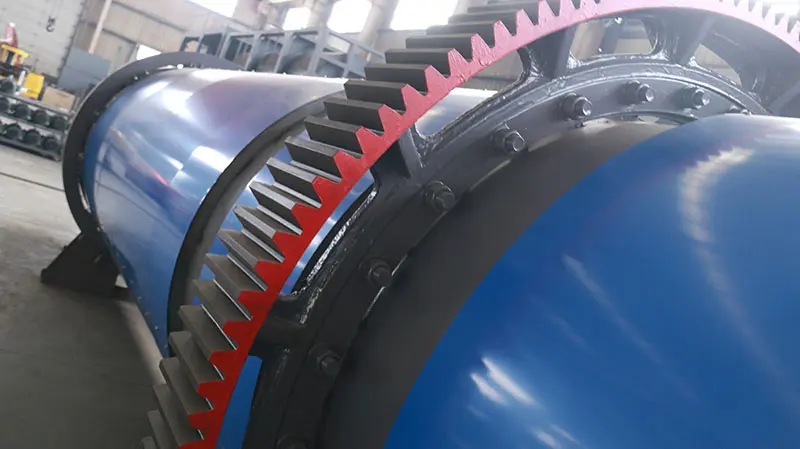

Lubricate all moving parts (bearings, rollers, gears) with manufacturer-recommended lubricants.

Inspect dryer tires for uneven wear, cracks, or pressure loss (for pneumatic tires).

Check drive belt tension and condition—replace worn or frayed belts to prevent slippage.

Clean burners (for fuel-fired dryers) to remove soot buildup and ensure efficient combustion.

Monthly Maintenance

Use laser alignment tools to verify shell and roller alignment; adjust shims or rollers to correct misalignment.

Inspect end seals and drum seals for wear or damage; replace to prevent hot air leakage.

Test safety components (temperature switches, pressure gauges, emergency stops) for functionality.

Examine internal flights (material lifters) for bending or wear; repair or replace to maintain uniform material mixing.

Quarterly/Annual Maintenance

Conduct a comprehensive inspection of the entire dryer, including the frame, shell, and drive system.

Overhaul the heating system: clean heat exchangers, inspect fuel lines, and calibrate burners.

Replace worn bearings, gears, or seals—proactive replacement avoids costly emergency repairs.

Calibrate sensors and controls (temperature, moisture, feed rate) for accurate operation.

Clean or replace dust collector filters to maintain air flow and environmental compliance.

Common Rotary Dryer Issues & Troubleshooting

Reduced Drying Efficiency: Caused by material buildup on heat exchangers, clogged air ducts, or inefficient combustion. Solution: Clean heat exchangers and ducts, inspect and adjust burners.

Uneven Drying: Stemming from misaligned shells, worn flights, or inconsistent feed rates. Solution: Realign the dryer, replace flights, and ensure uniform material feeding.

Unusual Noises: Indicative of worn bearings, misaligned gears, or loose components. Solution: Replace bearings, realign gears, and tighten fasteners.

Air/Material Leaks: Resulting from damaged seals. Solution: Replace worn seals and ensure proper installation.

Overheating: Caused by clogged exhaust ducts, faulty temperature sensors, or overloading. Solution: Clean ducts, replace sensors, and adjust feed rates.

Best Practices for Effective Rotary Dryer Maintenance

Follow manufacturer guidelines: Tailor maintenance schedules to your dryer’s model and operating conditions.

Train operators: Equip staff to perform basic inspections and report issues promptly.

Use quality parts: Invest in OEM or high-quality replacement parts (bearings, seals, lubricants) for durability.

Keep detailed logs: Track inspections, repairs, and part replacements to identify long-term performance trends.

Conduct seasonal checks: Adjust maintenance for extreme temperatures (e.g., winter lubrication for cold climates).