1. Core Working Principle Difference Between Ball Mill and Rod Mill

Ball Mill Working Principle

Rod Mill Working Principle

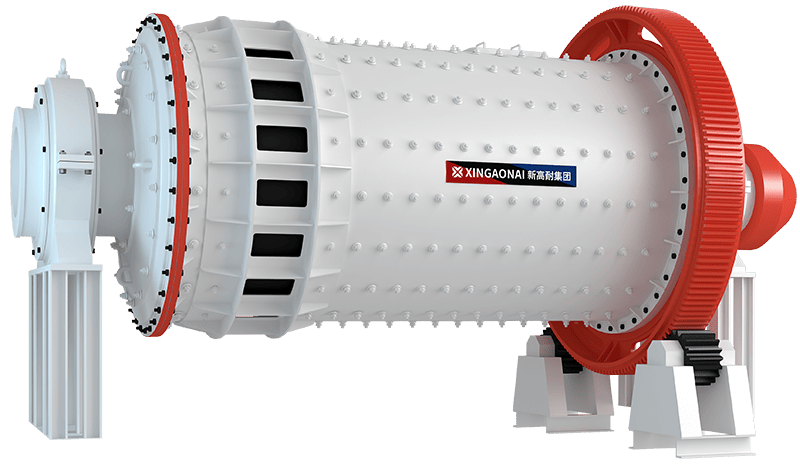

2. Structural Design Differences

Feature | Ball Mill | Rod Mill |

Grinding Medium | Steel/ceramic balls (diameters 20-150mm) | Steel rods (length 2-6m, diameter 50-120mm) |

Cylinder Length-Diameter Ratio | Shorter (L/D = 1-2.5), compact structure | Longer (L/D = 2.5-4), elongated cylinder |

Liner Design | Corrugated or grid liners to enhance ball lifting | Smooth or slightly grooved liners to prevent rod tangling |

Feed/Outlet Structure | Larger feed inlet, suitable for various particle sizes; discharge controlled by grids or diaphragms | Narrower feed inlet (to avoid rod jamming); discharge with sieve plates to retain oversized particles |

Rotation Speed | Higher (45-60 rpm) | Lower (30-45 rpm) |

3. Application Scope Difference Between Ball Mill and Rod Mill

Ball Mill Applications

Material Type: Ideal for hard, brittle, and abrasive materials (e.g., limestone, granite, iron ore, cement clinker) and soft materials (e.g., coal, gypsum).

Particle Size Requirement: Focus on fine grinding (product particle size 0.074-0.4mm) and ultra-fine grinding (even below 0.074mm).

- Industry Scenarios:

Mining: Ore beneficiation (e.g., grinding iron ore for magnetic separation, copper ore for flotation).

Cement: Grinding clinker and gypsum into cement powder.

Chemical: Grinding chemical raw materials (e.g., limestone for calcium carbonate production).

Powder Metallurgy: Ultra-fine grinding of metal powders.

Rod Mill Applications

Material Type: Suitable for brittle, non-abrasive, or sticky materials (e.g., limestone, coal, phosphate rock, clay) and materials requiring minimal over-grinding.

Particle Size Requirement: Primarily for coarse grinding (product particle size 1-3mm) and medium grinding (0.4-1mm), focusing on uniform particle size distribution.

- Industry Scenarios:

Mining: Primary grinding of ores to avoid over-grinding (e.g., gold ore, silver ore) and protect valuable minerals.

Aggregate Production: Grinding limestone or river pebbles into uniform medium-grain aggregates for construction.

Coal Processing: Grinding coal into uniform particles for power plants or coal chemical production.

Ceramic Industry: Grinding ceramic raw materials (e.g., clay, feldspar) with controlled particle size to ensure product quality.

4. Product Quality & Operational Characteristic Differences

Product Quality

Ball Mill: Produces finer particles but with wider particle size distribution, and may generate excessive fines (over-grinding) for some materials. Suitable for scenarios where fine particle size is prioritized.

Rod Mill: Delivers more uniform particle size distribution with minimal over-grinding, as the linear contact of steel rods ensures gentle grinding. Ideal for applications requiring consistent medium-grain products.

Operational Characteristics

Energy Consumption: Ball mills consume more energy per unit output due to higher rotation speed and impact-based grinding; rod mills are more energy-efficient for coarse/medium grinding.

Maintenance: Ball mill liners and steel balls wear faster (especially for abrasive materials), requiring frequent replacement; rod mills have lower wear on rods and liners, reducing maintenance frequency and costs.

Capacity: For the same cylinder volume, ball mills have higher capacity for fine grinding; rod mills have lower capacity but more stable output for coarse grinding.

5. Key Selection Guidelines: How to Choose Between Ball Mill and Rod Mill?

Particle Size Requirement: Choose a ball mill for fine/ultra-fine grinding (≤0.4mm); select a rod mill for coarse/medium grinding (≥0.4mm) with uniform particle size.

Material Properties: Use a ball mill for hard, abrasive materials; opt for a rod mill for brittle, non-abrasive, or sticky materials to avoid over-grinding or jamming.

Production Goals: Prioritize a ball mill if high fineness is critical (e.g., cement production); choose a rod mill if minimal over-grinding and uniform particle size are required (e.g., ore beneficiation, aggregate production).

Energy & Maintenance Budget: Rod mills are more cost-effective for long-term operation in coarse grinding scenarios; ball mills are better for applications where fine grinding justifies higher energy and maintenance costs.