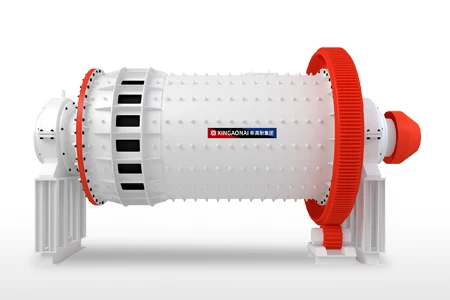

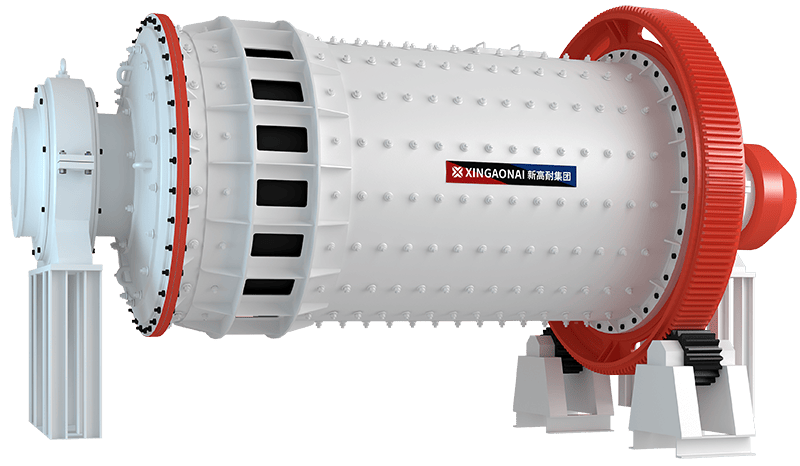

2. Key Features of Rod Mills

Uniform Particle Size: The steel rod grinding method reduces over-crushing, resulting in sand with a continuous gradation and low powder content, which improves the workability of concrete and mortar.

Good Particle Shape: The rolling and grinding action of steel rods produces rounder sand particles, enhancing the strength and durability of building materials.

Wide Material Adaptability: It can process various hard and brittle materials (Mohs hardness 5-10), including granite, basalt, limestone, and quartz, adapting to different sand making needs.

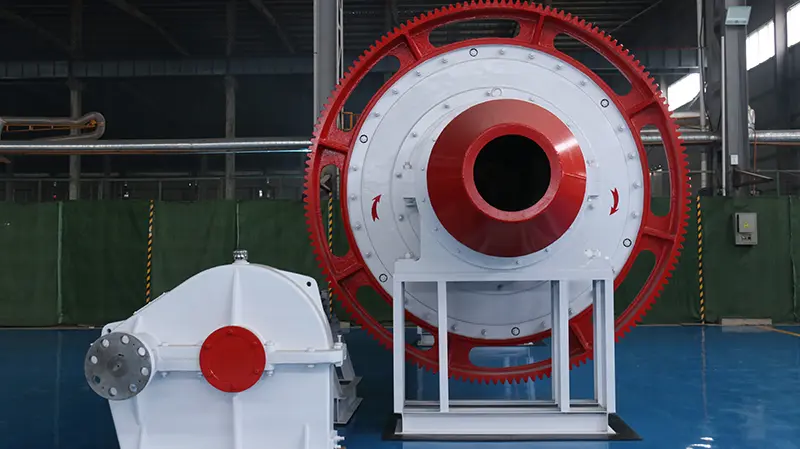

Stable Operation: The robust cylinder structure, high-quality steel rods, and optimized rotating speed ensure long-term stable operation with low failure rates.

Eco-Friendly Design: Equipped with dust collectors and noise reduction devices, it meets environmental protection standards for modern sand making projects.

3. Main Applications of Rod Mills

Construction Industry: Producing concrete sand, mortar sand, and dry-mixed mortar aggregates for residential buildings, commercial complexes, and industrial workshops.

Infrastructure Construction: Supplying qualified sand for highways, railways, bridges, tunnels, and water conservancy projects (e.g., dams, reservoirs).

Mining Industry: Grinding ore particles into fine sand for mineral processing (e.g., flotation, magnetic separation) or as auxiliary materials in ore dressing processes.

Green Building Materials: Manufacturing eco-friendly sand for recycled concrete, permeable bricks, and other green construction products.

4. Advantages Over Other Sand Making Equipment

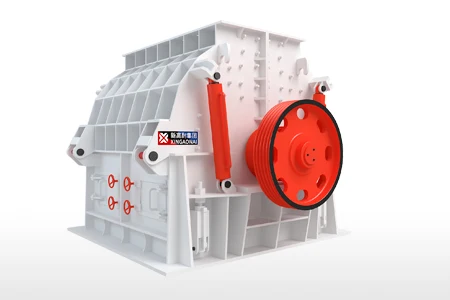

vs. Impact Sand Makers: Rod mills produce sand with more uniform particle size and lower powder content, avoiding the problem of excessive fine particles in impact-crushed sand.

vs. Ball Mills: Rod mills have higher grinding efficiency for sand making, as steel rods contact materials in a linear manner (rather than point contact like steel balls), reducing energy consumption and improving production capacity.

5. Selection Tips for Rod Mills

Raw Material Hardness: Select rod mills with appropriate steel rod materials (e.g., high-chromium steel rods for hard materials) to ensure grinding efficiency and rod durability.

Production Capacity: Match the mill’s output (usually 5-100 tons per hour) to your project’s sand demand.

Particle Size Requirements: Choose models with adjustable discharge devices to meet different gradation standards (e.g., fine sand for concrete, medium sand for mortar).

Energy Efficiency: Opt for rod mills with frequency conversion speed control to save energy and adapt to varying material conditions.