The

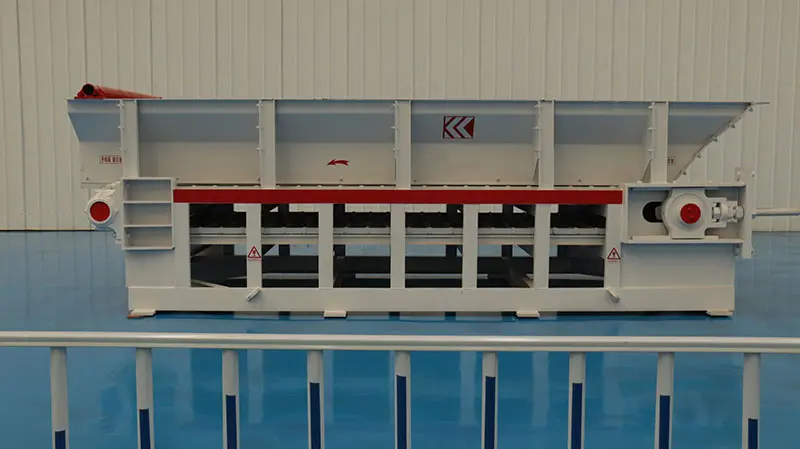

apron feeder (also known as a pan feeder) is a heavy-duty material handling equipment widely used in mining, metallurgy, aggregate production, and large-scale construction projects. Unlike light-duty feeding equipment, it is designed to convey and feed large, abrasive, and high-density bulk materials (such as ore, limestone, granite, and coal) with stable and uniform performance. Understanding the apron feeder working principle is essential for mining and industrial enterprises to optimize equipment operation, reduce downtime, and ensure the efficiency of the entire production line. This guide provides a detailed breakdown of the apron feeder working principle, along with supplementary insights into its core components, types, applications, and operational precautions.

Core Components of Apron Feeder (Foundation for Working Principle)

To fully grasp the apron feeder working principle, it is first necessary to understand its key structural components, as each part plays a vital role in the feeding process:

Apron Plates (Pan Plates): The core conveying component, usually made of high-strength manganese steel or alloy steel to resist wear and impact. Apron plates are connected end-to-end to form a continuous conveying surface, which directly bears and transports bulk materials.

Chain Drive System: Consists of high-strength roller chains, sprockets, and a drive shaft. It provides the power to drive the apron plates to move continuously. The chain system is designed to withstand heavy loads, ensuring stable power transmission even under harsh working conditions.

Drive Unit: The power source of the apron feeder, typically composed of an electric motor, reducer, and coupling. The motor converts electrical energy into mechanical energy, which is then transmitted to the chain drive system after speed reduction by the reducer, controlling the running speed of the apron plates.

Idler Rollers & Guide Rails: Idler rollers support the apron plate chain to reduce friction during movement, while guide rails limit the lateral displacement of the apron plates, ensuring stable and non-deviating operation.

Frame: Made of welded steel, it provides structural support for all components. The robust frame design ensures the apron feeder can withstand the impact of large bulk materials and operate stably for a long time.

Adjustment Mechanism: Used to adjust the feeding rate and the angle of the feeder (usually 0°–25°). By changing the running speed of the apron plates or the inclination angle of the feeder, the feeding capacity can be precisely controlled.

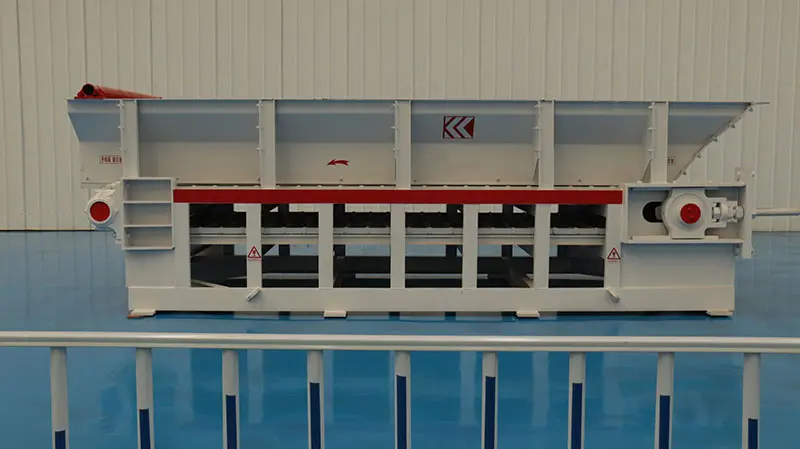

Detailed Apron Feeder Working Principle

The apron feeder working principle is based on the continuous cyclic movement of the apron plate chain, which realizes the uniform transportation and feeding of bulk materials. The entire working process can be divided into four key steps, with each component cooperating closely to ensure efficient operation:

1. Power Transmission & Chain Operation

When the apron feeder is started, the electric motor in the drive unit begins to operate. The high-speed rotation of the motor is converted into low-speed, high-torque rotation through the reducer (to meet the heavy-load feeding requirement). This torque is then transmitted to the drive shaft and sprockets via the coupling. As the sprockets rotate, they drive the meshed roller chains to move continuously. Since the apron plates are firmly connected to the chains, the apron plates also start to move along the guide rails and idler rollers at a constant speed.

2. Material Loading & Conveying

Bulk materials (such as large ore blocks) are discharged from the hopper, silo, or mine car onto the continuous apron plate chain at the feeding end of the apron feeder. Due to the high strength and wear resistance of the apron plates, they can easily withstand the impact of large and heavy materials without deformation or damage. As the apron plate chain moves forward continuously, the materials on the apron plates are driven to move forward together under the action of friction between the materials and the apron plates. During the conveying process, the idler rollers under the apron plates reduce the friction resistance, making the movement of the apron plate chain smoother and more energy-efficient.

3. Uniform Feeding to Downstream Equipment

When the materials are conveyed to the discharge end of the

apron feeder, they fall freely into the downstream processing equipment (such as jaw crushers, cone crushers, or screening machines) under the action of gravity. The key to the apron feeder working principle lies in "uniform feeding": by adjusting the running speed of the apron plates (via the drive unit) or the inclination angle of the feeder (via the adjustment mechanism), the amount of materials falling into the downstream equipment per unit time can be precisely controlled. This avoids overloading or underloading of the downstream crushing/screening equipment, ensuring the stability of the entire production line.

4. Cyclic Operation & Continuous Feeding

After the apron plates at the discharge end complete the material unloading, they continue to move along the lower part of the frame (return section) back to the feeding end. This forms a closed cyclic movement. As long as the drive unit operates continuously, the apron plate chain will cycle repeatedly, realizing the continuous and uninterrupted feeding of bulk materials. During the cyclic movement, the guide rails effectively prevent the apron plates from deviating, ensuring the long-term stable operation of the equipment.

Key Feature of Apron Feeder Working Principle: Adaptability to Heavy-Duty Conditions

A notable advantage of the apron feeder working principle is its strong adaptability to heavy-duty and harsh working conditions. Unlike vibrating feeders that may have blockage issues with large materials, the apron feeder uses a rigid apron plate chain to directly carry materials, which can handle materials with a maximum particle size of up to 1500mm and a density of 2.5–3.5 t/m³. The low-speed, high-torque operation mode also reduces the impact of materials on the equipment, extending the service life.

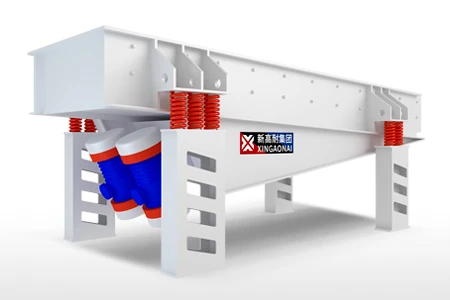

Types of Apron Feeders & Their Working Principle Differences

Based on structural design and application scenarios, apron feeders are mainly divided into two types, with slight differences in their working principles to adapt to different needs:

1. Heavy-Duty Apron Feeder

This type is designed for large-scale mining projects and heavy-load feeding scenarios. Its working principle emphasizes "high torque and stable bearing capacity": the drive unit uses a large-power motor and a hard-tooth surface reducer to provide sufficient power, and the apron plates are thickened and reinforced to withstand the impact of extra-large ore blocks. The frame is also designed with a heavy-duty structure to ensure stability under high-load operation. It is widely used in open-pit mines, metal ore beneficiation lines, etc.

2. Light-Duty/Medium-Duty Apron Feeder

Suitable for small to medium-scale aggregate production lines and coal processing plants, its working principle focuses on "energy efficiency and flexible adjustment". The drive unit uses a small-power motor, and the apron plates are relatively light. The adjustment mechanism is more flexible, allowing for stepless speed regulation to meet the precise feeding requirements of medium-grain materials (maximum particle size ≤500mm). It is often used in cement plants, coal washing plants, etc.

Applications of Apron Feeder (Based on Working Principle Advantages)

The unique working principle of the apron feeder—stable, uniform, and heavy-duty feeding—makes it widely used in various industries that involve bulk material processing:

Mining Industry: As the core front-end feeding equipment in metal mines (iron ore, copper ore) and non-metal mines (limestone, granite), it feeds large raw ore blocks into primary crushers uniformly, ensuring efficient crushing operations.

Metallurgical Industry: Feeds steel slag, iron ore concentrate, and other materials into smelting or processing equipment, withstanding high-temperature and high-abrasion working conditions.

Aggregate Production Industry: Transports limestone, river pebbles, and other raw materials to crushing and screening lines in highway, railway, and building construction projects, ensuring stable aggregate output.

Coal Processing Industry: Feeds coal from coal mines or coal yards into crushers, conveyors, or coal-fired boilers, adapting to coal with high moisture content without blockage.

Port & Bulk Material Handling: Used for loading and unloading bulk materials (such as ore, coal, and grain) at ports and terminals, realizing efficient and continuous material transfer.

Operational Precautions Based on Apron Feeder Working Principle

To ensure the apron feeder operates in accordance with its working principle and maintains long-term stability, the following operational precautions should be noted:

Avoid Overload Feeding: Do not feed materials exceeding the maximum particle size or feeding capacity, as this will overload the drive unit and chain system, leading to equipment failure.

Regular Lubrication: Lubricate the chain drive system, bearings, and idler rollers regularly to reduce friction, which is crucial for maintaining the smooth power transmission in the apron feeder working principle.

Check Component Wear: Regularly inspect the apron plates, chains, and sprockets for wear. Replace severely worn components in time to avoid affecting the uniform movement of the apron plate chain and the feeding effect.

Ensure Uniform Material Distribution: Ensure materials are evenly distributed on the apron plates to avoid uneven stress on the chain and apron plates, which may cause deviation or damage.

Startup & Shutdown Sequence: Start the apron feeder first before feeding materials, and stop feeding materials first before shutting down the feeder. This avoids material accumulation at the feeding end and protects the drive unit.

The

apron feeder working principle, centered on the continuous cyclic movement of the apron plate chain and precise power transmission, enables it to achieve stable, uniform, and heavy-duty feeding of bulk materials. This unique working mechanism makes it an indispensable core equipment in mining, metallurgy, and aggregate production lines.