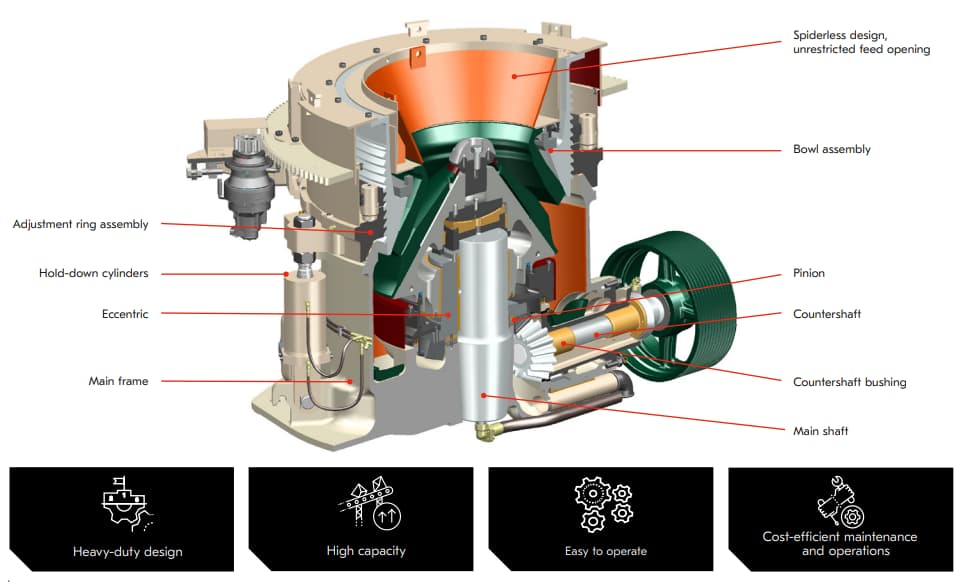

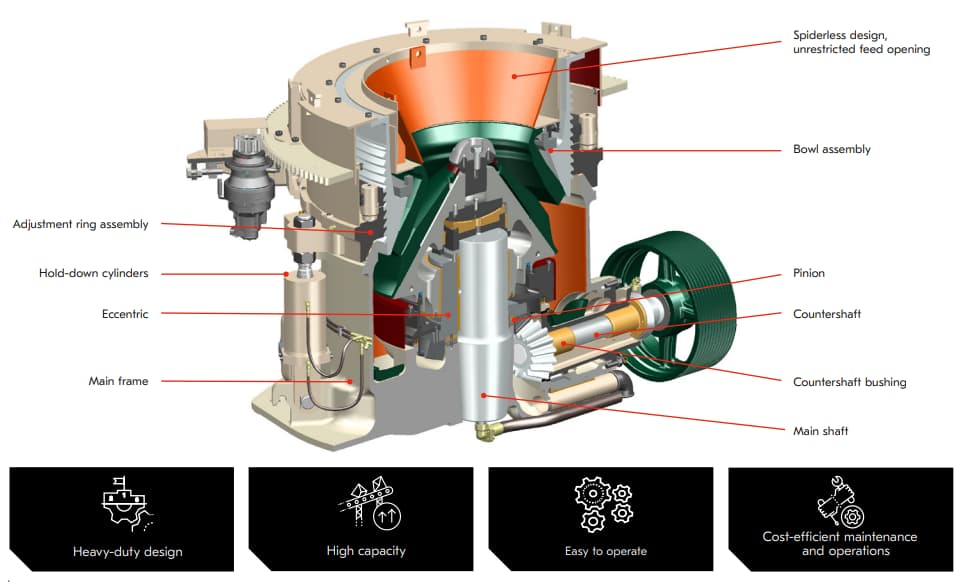

When it comes to understanding cone crushers, knowing the

cone crusher parts name is essential for operators, maintenance teams, and procurement professionals. Cone crushers are heavy-duty crushing equipment widely used in mining, quarrying, and construction to crush hard rocks and ores into uniform particles.

Each cone crusher part has a specific name and role, working together to ensure efficient, stable crushing performance. Below is a comprehensive guide to every cone crusher parts name, along with their functions and key details.

Core Cone Crusher Parts Name & Their Functions

The core cone crusher parts are the primary components responsible for the crushing action, designed to withstand high pressure, impact, and abrasion. Here are the key core cone crusher parts name and their roles:

1. Cone Mantle

The cone mantle is one of the most critical cone crusher parts name to remember. It is a wear-resistant component that covers the cone head, forming the moving part of the crushing chamber.

As the cone rotates, the cone mantle exerts compressive force on materials, crushing them against the stationary concave liner.

2. Concave Liner (Stationary Concave)

Another essential cone crusher parts name is the concave liner, also known as the stationary concave. It is a fixed, wear-resistant liner mounted on the inner wall of the crusher’s frame.

It forms the stationary side of the crushing chamber, working with the cone mantle to crush and shape materials into the desired particle size.

3. Cone Head (Crushing Cone)

The cone head, or crushing cone, is a conical component that connects to the main shaft. It is the base onto which the cone mantle is attached.

Driven by the main shaft, the cone head rotates eccentrically, moving the cone mantle to create the crushing action.

4. Main Shaft

The main shaft is a key structural cone crusher part name, responsible for transmitting power from the drive system to the cone head.

It is made of high-strength alloy steel to withstand heavy loads and eccentric rotation during crushing operations.

5. Eccentric Sleeve

The eccentric sleeve is a cylindrical component that fits around the main shaft. It is a crucial cone crusher parts name related to the crusher’s movement.

As the eccentric sleeve rotates, it causes the main shaft and cone head to move eccentrically, generating the compressive force needed for crushing.

6. Transmission Gear (Bevel Gear Pair)

The transmission gear, often a bevel gear pair, is an important cone crusher parts name for power transmission.

It connects the motor to the eccentric sleeve, converting the motor’s rotational energy into the eccentric movement of the main shaft and cone head.

Auxiliary Cone Crusher Parts Name & Their Roles

Auxiliary cone crusher parts support the core crushing process, ensuring smooth operation, safety, and long equipment lifespan. Below are the key auxiliary cone crusher parts name and their functions:

1. Frame (Crusher Frame)

The frame, or crusher frame, is a heavy-duty structural

cone crusher part name that houses all other components.

Made of welded steel or cast iron, it provides stability and support, absorbing the impact and pressure generated during crushing.

2. Drive Motor

The drive motor is a fundamental auxiliary cone crusher parts name, serving as the power source for the entire crusher.

It supplies electrical energy to the transmission system, which then drives the core crushing components.

3. Bearings (Main Bearings)

Bearings, specifically main bearings, are essential cone crusher parts name that support the rotating main shaft.

They reduce friction between the main shaft and fixed components, ensuring smooth, efficient rotation and preventing overheating.

4. Lubrication System

The lubrication system is a critical auxiliary cone crusher parts name, responsible for lubricating bearings, gears, and other moving components.

It supplies grease or oil to minimize friction and wear, extending the service life of all cone crusher parts.

5. Hydraulic Adjustment System

The hydraulic adjustment system is a key cone crusher parts name for controlling the discharge particle size.

It allows operators to adjust the gap between the cone mantle and concave liner, adapting to different crushing requirements.

6. Feed Hopper & Chute

The feed hopper and chute are auxiliary cone crusher parts name that manage material flow into the crushing chamber.

The feed hopper collects bulk materials, while the chute guides them evenly into the chamber, preventing uneven loading and equipment imbalance.

7. Safety Guards

Safety guards are an important cone crusher parts name for worker protection. They cover moving components like gears and belts.

They comply with industrial safety standards, preventing accidents during operation and maintenance.

Key Notes About Cone Crusher Parts Name & Maintenance

Knowing each cone crusher parts name is the first step in proper equipment maintenance. Wear parts like the cone mantle and concave liner need regular inspection and replacement.

Using the correct name for each cone crusher part ensures clear communication between teams, simplifying maintenance, troubleshooting, and parts replacement.

Material Selection for Common Cone Crusher Parts

Wear parts (cone mantle, concave liner): High-manganese steel, alloy steel, or composite materials for excellent abrasion resistance.

Structural parts (frame, main shaft): High-strength alloy steel or cast iron for rigidity and durability.

Maintenance Tips for Cone Crusher Parts

Regularly inspect wear parts (cone mantle, concave liner) and replace them when wear exceeds 50% of their thickness.

Monitor the lubrication system to ensure proper oil/grease levels and quality, preventing bearing and gear damage.

Check the hydraulic adjustment system for leaks and ensure it operates smoothly to maintain consistent discharge size.

Clean the feed hopper and chute regularly to prevent material buildup and uneven loading.

Conclusion

Understanding every

cone crusher parts name and its function is crucial for optimizing crusher performance, reducing downtime, and extending equipment lifespan. From core parts like the cone mantle and concave liner to auxiliary parts like the lubrication system and feed hopper, each component plays a vital role.

This guide provides a complete list of cone crusher parts name, making it easy for operators, maintenance teams, and procurement professionals to identify, maintain, and replace parts as needed—ensuring efficient, reliable crushing in mining, construction, and aggregate industries.