Jaw crushers and gyratory crushers are two of the most widely used primary crushing equipment in mining, quarrying, and construction industries. While both are designed to reduce large rock and ore into smaller particles, the difference between jaw crusher and

gyratory crusher is significant—from their structure and working principles to their efficiency and ideal applications.

Understanding these differences is critical for operators, project managers, and procurement teams to select the right crushing equipment for their specific needs, optimizing productivity and reducing operational costs.

Core Difference Between Jaw Crusher and Gyratory Crusher: Overview

The fundamental difference between jaw crusher and gyratory crusher lies in their structural design and crushing mechanism. A jaw crusher uses a reciprocating jaw plate to exert compressive force, while a gyratory crusher relies on a rotating conical head for continuous crushing.

This core distinction leads to variations in their performance, efficiency, and suitability for different materials and project scales.

Key Differences Between Jaw Crusher and Gyratory Crusher (Detailed Comparison)

Below is a detailed breakdown of the main differences between

jaw crusher and gyratory crusher, covering structure, working principle, efficiency, and more:

1. Structural Design

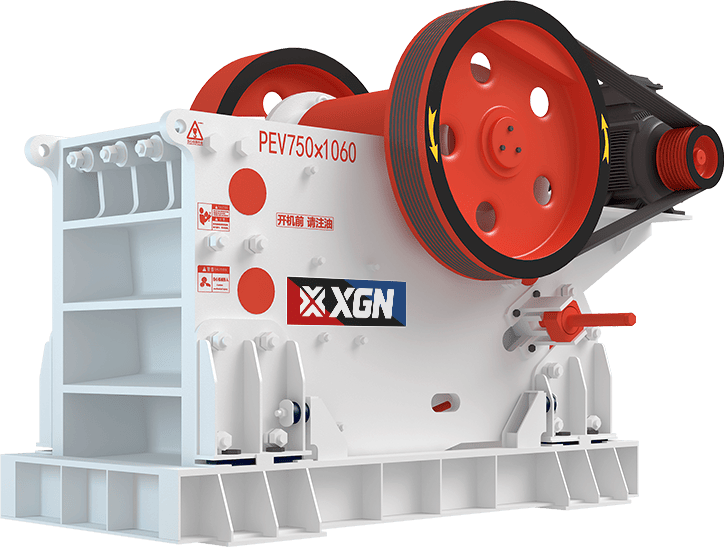

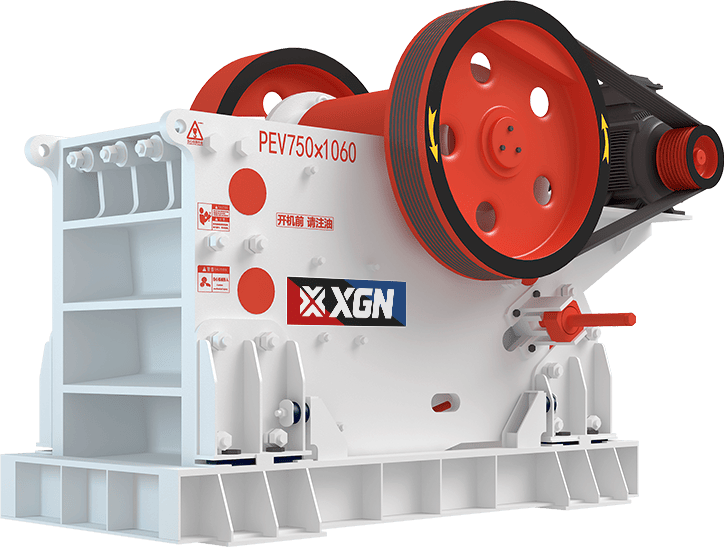

Jaw Crusher: A jaw crusher has a simple, compact structure consisting of a fixed jaw plate, a movable jaw plate, a toggle plate, and a drive system. The two jaw plates form a V-shaped crushing chamber, with the movable jaw moving back and forth against the fixed jaw.

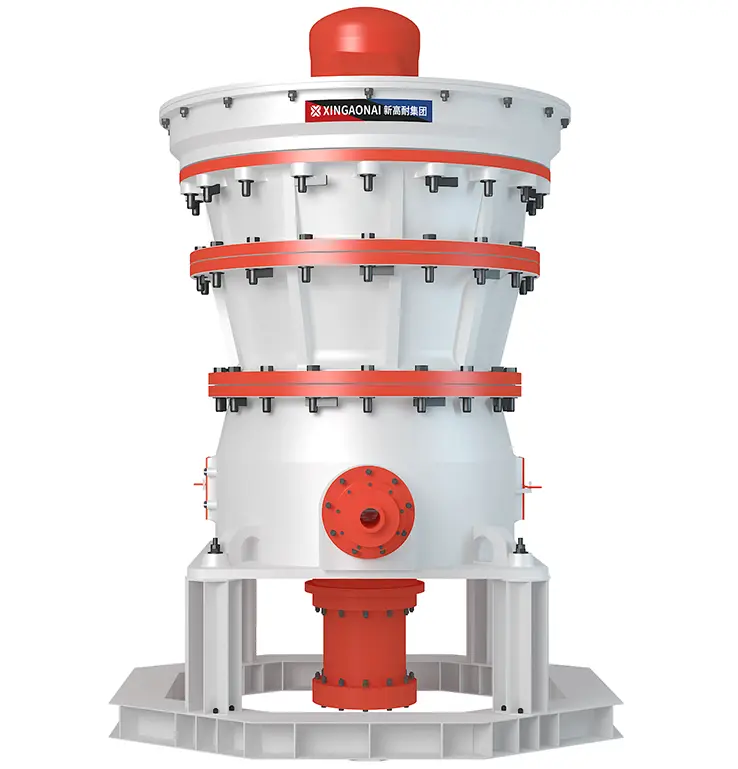

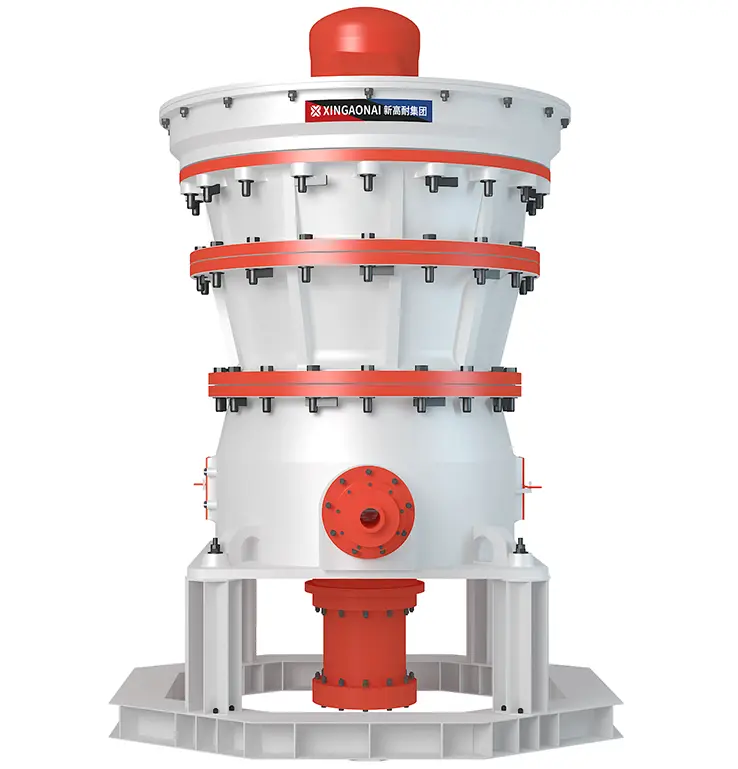

Gyratory Crusher: A gyratory crusher has a more complex structure, including a fixed concave liner (outer cone), a rotating conical head (inner cone), an eccentric sleeve, a main shaft, and a heavy-duty frame. The crushing chamber is a conical space between the outer and inner cones.

2. Working Principle

Jaw Crusher: The working principle of a jaw crusher is based on reciprocating compressive force. The drive system moves the toggle plate, which causes the movable jaw to swing back and forth—closing against the fixed jaw to crush materials, then opening to allow crushed particles to discharge.

Gyratory Crusher: A gyratory crusher operates using continuous compressive force. The eccentric sleeve drives the main shaft and conical head to rotate eccentrically, causing the inner cone to move closer to and away from the outer cone continuously. Materials are crushed gradually as they move down the conical chamber.

3. Crushing Efficiency & Capacity

Jaw Crusher: Jaw crushers have a lower crushing efficiency compared to gyratory crushers. They operate in intermittent (batch) mode, with crushing and discharge happening in cycles. Their capacity is suitable for small to medium-scale projects, typically ranging from 1 to 1000 tons per hour.

Gyratory Crusher: Gyratory crushers offer higher crushing efficiency and larger capacity. They operate in continuous mode, with constant crushing and discharge, making them ideal for large-scale, high-volume projects. Their capacity can reach up to 10,000 tons per hour or more.

4. Crushing Ratio & Particle Size

Jaw Crusher: The crushing ratio of a jaw crusher is relatively low, usually between 6:1 and 10:1. It produces uneven particle sizes, with more needle-like and flaky particles, making it suitable for primary crushing only (reducing large rocks to manageable sizes for secondary crushing).

Gyratory Crusher: Gyratory crushers have a higher crushing ratio, ranging from 8:1 to 15:1. They produce more uniform, cubical particles with fewer impurities, making them suitable for both primary and secondary crushing in some applications.

5. Material Adaptability

Jaw Crusher: Jaw crushers are highly adaptable to various materials, including hard, abrasive rocks (e.g., granite, basalt) and brittle materials (e.g., limestone, coal). They can handle materials with compressive strength up to 320 MPa, making them versatile for different industries.

Gyratory Crusher: Gyratory crushers are also suitable for hard materials but perform best with medium-hard to hard ores and rocks. They are less effective with highly abrasive materials, as this can cause excessive wear on the conical head and concave liner.

6. Maintenance & Operational Cost

Jaw Crusher: Jaw crushers have a simple structure with fewer moving parts, leading to lower maintenance costs. Wearing parts (jaw plates, toggle plates) are easy to replace, and daily operation requires minimal technical expertise.

Gyratory Crusher: Gyratory crushers have a complex structure with more moving components (eccentric sleeve, main shaft, bearings), resulting in higher maintenance and operational costs. Their wearing parts (conical head, concave liner) are more expensive to replace, and maintenance requires skilled technicians.

7. Space Requirement

Jaw Crusher: Jaw crushers are compact and require less floor space, making them ideal for projects with limited installation space (e.g., small quarries, on-site construction crushing).

Gyratory Crusher: Gyratory crushers are large, heavy machines that require significant floor space and a strong foundation. They are typically used in large mining sites and quarries with ample space for installation.

Applications: When to Choose Jaw Crusher vs. Gyratory Crusher

Understanding the difference between jaw crusher and gyratory crusher helps in selecting the right equipment for specific applications:

Ideal for Jaw Crushers

Small to medium-scale primary crushing projects (e.g., small quarries, construction waste processing).

Projects with limited installation space or budget constraints.

Crushing highly abrasive or hard materials (e.g., granite, basalt) where simplicity and durability are prioritized.

Applications where particle size uniformity is not a critical requirement (e.g., road base materials).

Ideal for Gyratory Crushers

Large-scale, high-volume primary or secondary crushing projects (e.g., large mines, aggregate production lines).

Projects where high crushing efficiency and uniform particle size are critical (e.g., concrete aggregate, high-grade ore processing).

Long-term, continuous operation scenarios where high capacity is required to meet production targets.

Summary of the Difference Between Jaw Crusher and Gyratory Crusher

In summary, the key difference between

jaw crusher and gyratory crusher is their structural design and working mechanism—jaw crushers use reciprocating motion for intermittent crushing, while gyratory crushers use eccentric rotation for continuous crushing.

Jaw crushers are simpler, more compact, and cost-effective, suitable for small to medium projects. Gyratory crushers are more efficient, higher-capacity, and produce better particle quality, ideal for large-scale industrial applications.

Conclusion

Choosing between a jaw crusher and a gyratory crusher depends on your project scale, material type, capacity requirements, budget, and space constraints. By understanding the detailed difference between jaw crusher and gyratory crusher, you can make an informed decision that optimizes productivity, reduces costs, and meets your specific crushing needs.

Both crushers play a vital role in the mining and construction industries, and their unique advantages make them indispensable for different types of crushing applications.