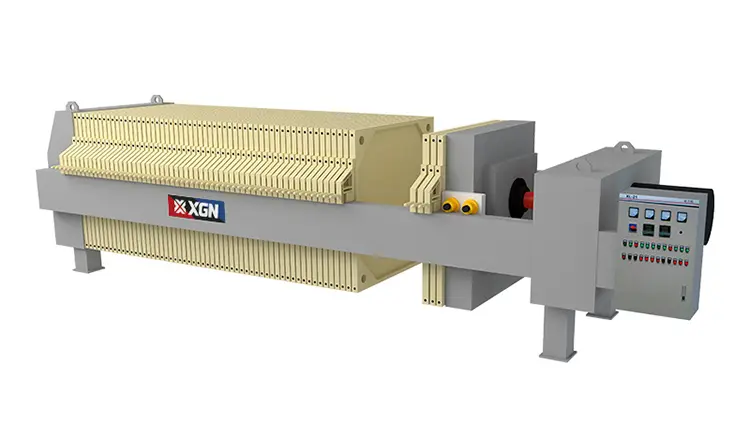

Whether for equipment setup, troubleshooting, or training, a clear plate and frame filter press diagram is indispensable in industries like chemical processing, mining, wastewater treatment, and food production.

1. Key Components Highlighted in a Plate and Frame Filter Press Diagram

Every standard plate and frame filter press diagram labels core components, each with a distinct role in the separation process. These labeled parts ensure clarity for anyone using the diagram.

1.1 Filter Plates & Frames

The diagram prominently features alternating filter plates and frames— the heart of the equipment. Plates are typically made of polypropylene or stainless steel, with recessed surfaces that form filtration chambers when clamped together.

Frames separate the plates, creating space for slurry to flow and solids to accumulate as filter cakes. The diagram shows their arrangement in a horizontal or vertical configuration, depending on the model.

1.2 Filter Cloth

A plate and frame filter press diagram often overlays filter cloth on plates, indicating its position as the filtration medium. The cloth traps solids while allowing liquid (filtrate) to pass through.

Diagrams may note cloth material (e.g., polyester, polypropylene) and attachment points, helping users identify replacement areas.

1.3 Clamping Mechanism

The clamping mechanism—either manual, hydraulic, or mechanical—is clearly marked in the diagram. It secures plates and frames tightly to prevent slurry leakage during operation.

Hydraulic cylinders or handwheels are shown at the end of the press, with arrows indicating clamping and releasing directions.

1.4 Slurry Inlet & Filtrate Outlets

The diagram labels the slurry inlet (where the solid-liquid mixture enters) and filtrate outlets (where separated liquid exits). These ports are strategically placed to ensure uniform distribution across filtration chambers.

Arrows in the diagram show the flow path of slurry and filtrate, simplifying the understanding of the separation process.

1.5 Cake Discharge System

For automatic or semi-automatic models, the plate and frame filter press diagram includes cake discharge components—such as plate shakers or pushers—that remove accumulated solids (filter cake) after filtration.

The diagram illustrates how plates open sequentially to release the cake, guiding maintenance of the discharge mechanism.

1.6 Frame & Support Structure

The diagram outlines the sturdy frame and support structure that bears the weight of plates, frames, and the clamping mechanism. It highlights structural rails that guide plate movement during clamping and discharge.

This part of the diagram helps in assessing equipment stability and planning installation space.

2. How to Read a Plate and Frame Filter Press Diagram

Interpreting a plate and frame filter press diagram requires understanding layout logic and symbols, which simplifies equipment operation and maintenance.

2.1 Identify Component Labels

Start by cross-referencing labeled parts with the equipment manual. Most diagrams use standard abbreviations (e.g., “FP” for filter plate, “FI” for filtrate inlet) for consistency.

2.2 Follow Flow Directions

Arrows indicate the path of slurry, filtrate, and hydraulic fluid (for clamping). Tracing these paths helps diagnose flow blockages or leakage issues.

2.3 Note Operational Positions

Diagrams often show two states: clamped (filtration mode) and unclamped (discharge mode). This helps operators verify correct equipment positioning during setup.

2.4 Locate Maintenance Points

Key maintenance areas—such as filter cloth replacement points, hydraulic cylinder connections, and seal locations—are highlighted for easy access reference.

3. Industrial Applications of Plate and Frame Filter Press Diagrams

A plate and frame filter press diagram is a practical tool across industries where solid-liquid separation is critical.

3.1 Chemical Industry

Diagrams guide the setup of filter presses for separating chemical slurries, ensuring compliance with product purity standards. They help in optimizing filtration of catalysts, dyes, and chemical intermediates.

3.2 Mining & Mineral Processing

In mining, the diagram aids in configuring equipment for dewatering ore slurries, separating valuable minerals from tailings. It supports efficient operation in gold, copper, and coal processing plants.

3.3 Wastewater Treatment

Wastewater treatment facilities use the diagram to maintain filter presses that separate sludge from treated water, ensuring compliance with environmental discharge regulations.

3.4 Food & Pharmaceutical Industry

Diagrams help in sanitizing and maintaining filter presses for food processing (e.g., juice clarification, edible oil filtration) and pharmaceutical production (e.g., drug ingredient purification), meeting GMP standards.

4. Importance of a Plate and Frame Filter Press Diagram

A well-designed plate and frame filter press diagram reduces operational errors, speeds up maintenance, and lowers training costs. It serves as a universal reference for teams across shifts and locations.

For procurement, the diagram helps compare models by visualizing component layout and functionality, ensuring the selected equipment meets process requirements.

5. Conclusion

A plate and frame filter press diagram is more than a technical drawing—it’s a foundational tool for understanding, operating, and maintaining this critical separation equipment. By highlighting key components, flow paths, and operational states, it simplifies complex processes for industrial users.

Whether for training new operators, troubleshooting issues, or selecting equipment, a clear plate and frame filter press diagram enhances efficiency and reliability in solid-liquid separation workflows.