In the global aggregate processing industry, the aggregate

vibrating screen is an irreplaceable core equipment that bridges raw material crushing and finished product classification. From quarries extracting granite and limestone to sand-making plants producing construction sand, and even construction waste recycling facilities, the aggregate vibrating screen directly determines the particle size uniformity, impurity content, and production efficiency of final aggregates. This article explores the working mechanism, key types, practical applications, and unique advantages of the aggregate vibrating screen, helping industry professionals make informed decisions.

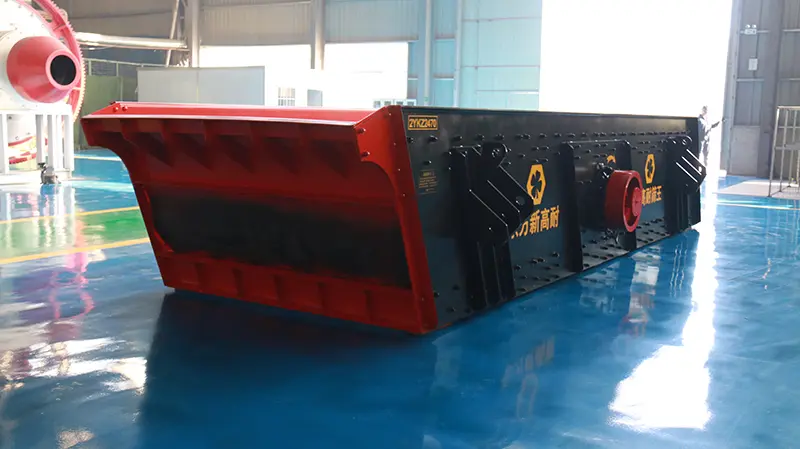

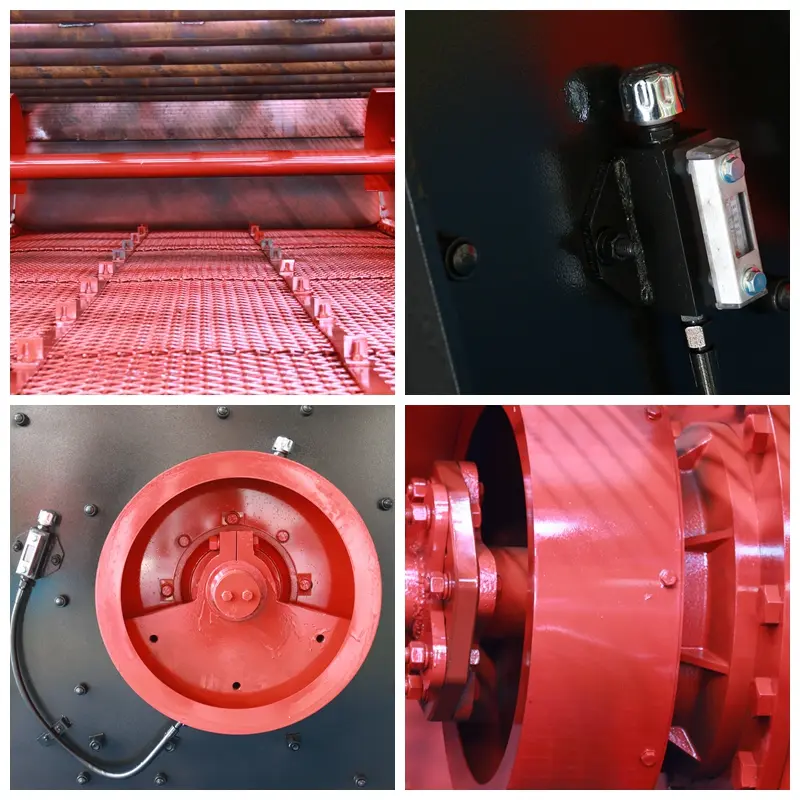

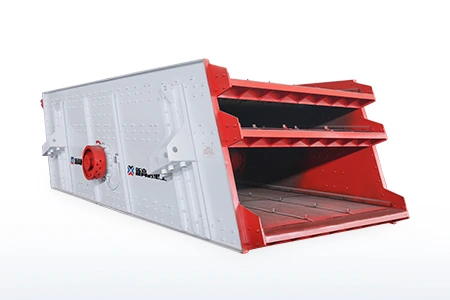

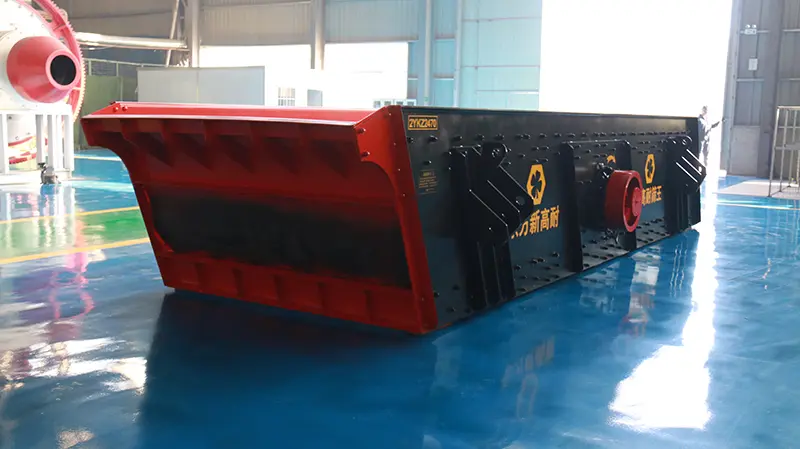

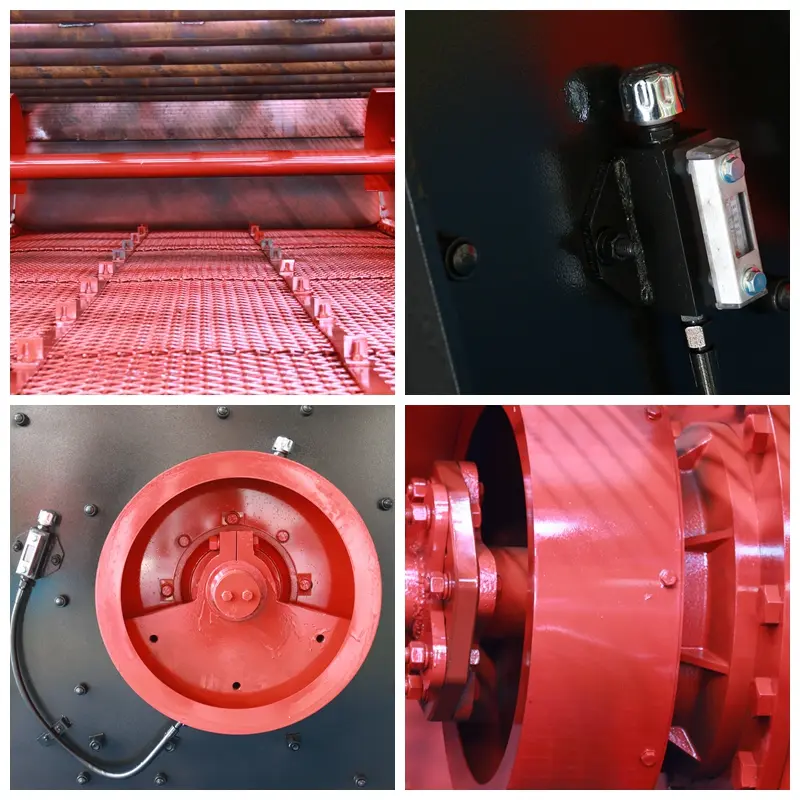

The core working principle of an aggregate vibrating screen relies on the synergy of mechanical vibration and gravitational force. A standard aggregate vibrating screen consists of a screen box, vibrator (electric motor-driven), suspension/support structure, and transmission system. When activated, the vibrator generates high-frequency, regular vibrations that are transmitted to the screen surface via the screen box.

As aggregate materials (such as crushed stone, sand, or recycled concrete) are fed onto the vibrating screen surface, particles smaller than the screen mesh size pass through smoothly—classified as qualified products. Larger particles move forward along the inclined screen surface under vibration force and are discharged as oversize materials (often recycled back to crushers for reprocessing). The adjustable vibration frequency and amplitude of modern aggregate vibrating screens allow seamless adaptation to different material properties, from dry, granular gravel to high-moisture construction waste, ensuring consistent screening accuracy.

Different aggregate processing scenarios require specialized aggregate vibrating screens. Based on vibration trajectory and structural design, three main types dominate the market:

Equipped with a dual-vibrator structure, the linear aggregate vibrating screen produces a straight-line vibration trajectory. It stands out for its large processing capacity, high screening efficiency, and uniform material discharge—making it the preferred choice for large-scale aggregate production lines, such as quarry crushing systems and commercial sand-making plants. This type of aggregate vibrating screen excels at separating granular or powdery aggregates into multiple grades (e.g., 0-5mm, 5-10mm) with precision.

Driven by a single vibrator, the circular aggregate

vibrating screen features a circular vibration trajectory. It offers strong adaptability to materials with uneven particle sizes or high moisture content, as the circular motion prevents clogging and ensures continuous processing. Widely used in coarse screening stages (e.g., separating large boulders from raw quarry materials), this aggregate vibrating screen is favored by small-to-medium processing plants for its simple structure, easy maintenance, and stable operation.

Designed with a high-frequency vibrator, the high-frequency aggregate vibrating screen generates small-amplitude, high-frequency vibrations. This design is perfect for fine screening tasks, such as removing fine powder from sand or classifying high-purity aggregates for high-grade concrete. The high-frequency aggregate vibrating screen effectively improves the quality of fine aggregates by enhancing particle separation, making it indispensable in premium construction and asphalt production.

The versatility of the aggregate vibrating screen makes it a staple in multiple industries:

Quarrying Industry: Classifies crushed granite, limestone, and basalt into graded aggregates for road construction, railway ballast, and building foundations.

Sand-Making Industry: Works with VSI crushers to refine artificial sand, adjusting particle size distribution and removing impurities to meet construction sand standards.

Construction Waste Recycling: Separates recycled aggregate from concrete debris, brick, and asphalt waste—promoting resource reuse and environmental sustainability.

Mining Industry: Screens ore and gangue, separating valuable minerals from waste rock to optimize mineral processing efficiency.

Investing in a premium aggregate vibrating screen delivers long-term value for processing enterprises:

Enhanced Efficiency: Optimized screen design and powerful vibration systems boost processing capacity, reducing production time and operational costs.

Uniform Product Quality: Precise mesh sizes and stable vibration ensure consistent aggregate grading, meeting industry quality standards for construction and infrastructure projects.

Durability & Reliability: Wear-resistant screen surfaces and robust structural materials (e.g., high-carbon steel) resist abrasion from hard aggregates, extending equipment lifespan and reducing maintenance frequency.

Flexible Adaptability: Adjustable vibration parameters (frequency, amplitude) and interchangeable screen meshes allow the aggregate vibrating screen to handle diverse materials and meet custom grading requirements.

Selecting the optimal aggregate vibrating screen requires considering three key factors:

Material Properties: For high-moisture materials, choose a circular aggregate vibrating screen; for fine screening, opt for a high-frequency model.

Production Requirements: Large-scale lines need linear aggregate vibrating screens for high capacity; small plants may benefit from compact circular models.

Reliability & After-Sales: Partner with reputable manufacturers to ensure access to genuine spare parts and professional maintenance support—critical for minimizing downtime.

As the backbone of aggregate processing, the aggregate vibrating screen plays a pivotal role in balancing efficiency, quality, and sustainability. Its diverse types, flexible applications, and technical advancements make it indispensable for modern construction, mining, and recycling projects.