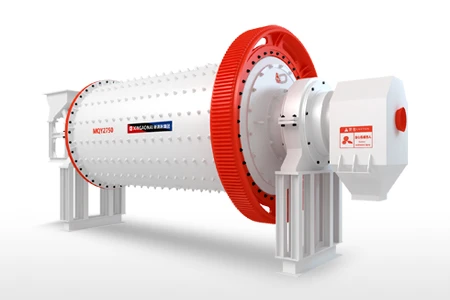

The MQY Series ball mill is a cornerstone of industrial grinding, designed to process ores, cement, chemicals, and construction materials with precision and efficiency. As a key component in mining, cement, and chemical operations, this mill leverages advanced technology to optimize grinding processes while minimizing energy consumption and environmental impact. This article delves into the ball mill applications across diverse industries, highlighting its benefits, operational versatility, and maintenance best practices.

Key Applications of MQY Series Ball Mills

Mining and Metallurgy

Ore Processing: MQY ball mills excel in grinding metallic and non-metallic ores (e.g., gold, copper, iron, limestone) to fine powders for subsequent extraction or beneficiation.

Pre-Screening Efficiency: Paired with vibrating screens like those mentioned in aggregate processing, these mills ensure consistent particle size distribution for downstream processes.

Cement Production

Clinker Grinding: MQY mills crush clinker, gypsum, and additives to produce high-quality cement, enhancing strength and durability in construction materials.

Wet and Dry Grinding: Supports both methods, adapting to raw material moisture levels for optimal throughput.

Chemical and Construction Industries

Chemical Processing: Grinds pigments, fillers, and raw materials for paints, coatings, and pharmaceuticals, ensuring uniform particle size for quality control.

Aggregate Recycling: Processes demolition waste and recycled aggregates into reusable materials, promoting sustainability in construction.

Ceramics and Glass: Produces fine powders for ceramics, glass, and refractory materials, improving product consistency.

Energy and Environmental Applications

Coal Grinding: Prepares coal for power generation, improving combustion efficiency and reducing emissions.

Waste Management: Grinds industrial waste for safe disposal or repurposing, aligning with circular economy principles.

Advantages of MQY Series Ball Mills

High Throughput: Designed for continuous operation with capacities ranging from 0.65 to 615 t/h, meeting large-scale industrial demands.

Dual Grinding Modes: Supports both wet and dry grinding, offering flexibility for diverse material characteristics.

Eco-Friendly Design: Closed-loop systems minimize dust emissions, while energy-efficient motors reduce operational costs.

Robust Construction: Wear-resistant materials extend component life, reducing maintenance downtime.

Automated Controls: PLC systems enable precise monitoring and adjustment, enhancing process stability.

Maintenance for Long-Term Performance

Regular Inspections: Check grinding media, liners, and bearings for wear or damage.

Lubrication: Ensure moving parts are well-lubricated to reduce friction and extend lifespan.

Tension Adjustment: Maintain optimal screen tension in vibrating screens paired with the mill to avoid clogging.

Cleaning: Remove accumulated material to prevent contamination and ensure smooth operation.

Selecting the Right MQY Ball Mill

Choosing the appropriate model depends on factors such as material type, desired particle size, throughput requirements, and operational environment. Key considerations include:

Material Properties: Hardness, moisture content, and abrasiveness influence mill selection.

Capacity Needs: Match mill size to production goals to avoid underutilization or overloading.

Environmental Regulations: Opt for low-emission models in regions with strict environmental standards.

Integration Potential: Ensure compatibility with existing equipment like vibrating screens for seamless workflows.

Conclusion

The MQY Series ball mill is indispensable in modern industry, offering unmatched versatility in grinding applications. By understanding its capabilities in mining, cement, chemicals, and construction, operators can unlock efficiency gains, reduce costs, and support sustainable practices. Whether processing ores, cement, or recycled materials, the right MQY ball mill ensures reliable performance and long-term value.