1. What Is a Mining PEV Series Jaw Crusher?

2. Working Principle of PEV Series Mining Jaw Crusher

Raw ore (crushed to a maximum feed size of 350–900mm, depending on the model) is fed into the crushing cavity through a heavy-duty feed hopper.

The eccentric shaft, driven by a high-power motor and V-belt pulley, rotates to drive the movable jaw plate in a reciprocating motion (close to and away from the fixed jaw plate).

The ore is crushed by the compressive force between the two jaw plates, gradually reducing in size until it meets the required discharge granularity (adjustable from 10–150mm).

The adjusted discharge gap ensures uniform particle size, which is critical for subsequent mineral processing steps such as grinding and beneficiation.

A safety device (e.g., hydraulic overload protection) is integrated to prevent damage from uncrushable materials (e.g., metal debris) – a common risk in mining operations.

3. Key Features of PEV Series Mining Jaw Crusher

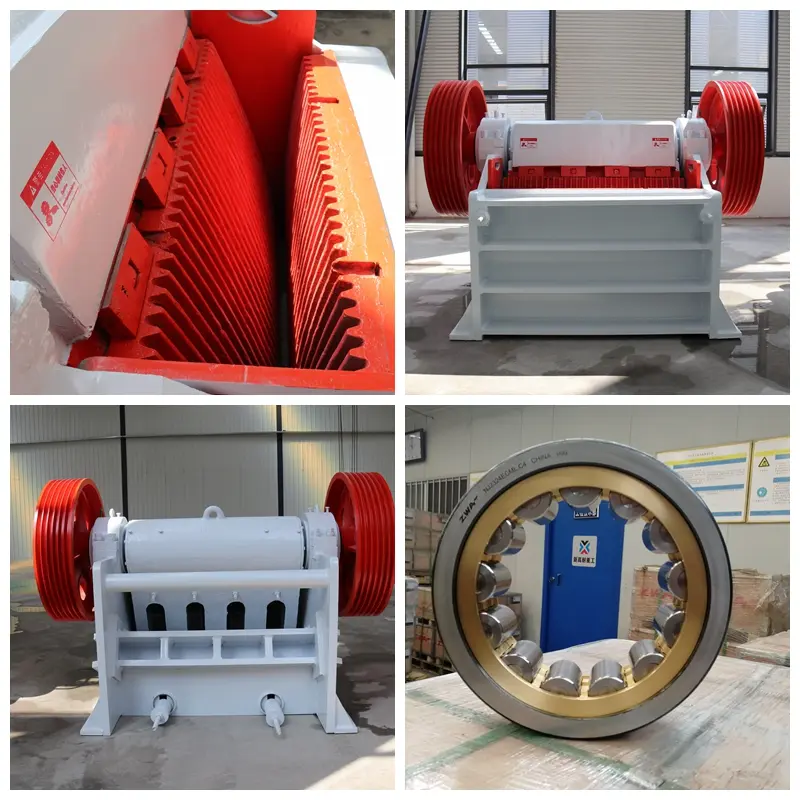

Robust & Wear-Resistant: High-strength welded frame and manganese steel jaw plates (Mn13Cr2) resist impact and abrasion from hard ore, extending service life and reducing replacement frequency.

High Crushing Efficiency: Optimized cavity design (deep V-shaped cavity) increases the crushing ratio (up to 6:1) and handling capacity, ensuring continuous operation even with high-volume ore feed.

Easy Adjustment & Maintenance: Wedge-type discharge gap adjustment allows quick granularity tuning, while accessible components (e.g., jaw plates, bearings) simplify routine maintenance – critical for minimizing mining downtime.

Energy-Saving Performance: Advanced motor matching and transmission system reduce power consumption by 10–15% compared to traditional jaw crushers, lowering long-term operating costs for mining projects.

Stable Operation: Heavy-duty eccentric shaft and reinforced bearing seats improve load-bearing capacity, ensuring stable performance under fluctuating ore feed conditions (common in mining sites).

4. Applications of PEV Series Mining Jaw Crusher

Metal Ore Mining: Ideal for primary crushing of iron ore, copper ore, gold ore, nickel ore, and lead-zinc ore – preparing ore for beneficiation processes (flotation, magnetic separation).

Non-Metal Ore Mining: Processes limestone, granite, basalt, quartz, and dolomite for aggregate production, construction materials, or industrial raw materials.

Quarry & Aggregate Production: Crushes rock into qualified aggregates for highway, railway, and building construction – a key auxiliary application in mining-related infrastructure.

Open-Pit & Underground Mines: Suitable for both open-pit mining (large-scale, high-capacity requirements) and underground mining (compact design for limited space).

5. Advantages of PEV Series Over Other Mining Jaw Crushers

Higher Durability: Wear-resistant components and reinforced structure withstand the harsh conditions of mining (e.g., dust, heavy loads, continuous operation) better than generic models.

Wider Capacity Range: From 20tph to 600tph, it adapts to small-scale artisanal mines and large-scale industrial mining projects alike.

Lower Operating Costs: Energy-saving design and long-lasting parts reduce electricity consumption and maintenance expenses – a critical factor for mining profitability.

Better Particle Size Control: Deep V-cavity and precise gap adjustment ensure uniform discharge, improving the efficiency of downstream mining processes (e.g., grinding, sorting).

6. How to Choose the Right PEV Series Mining Jaw Crusher

Ore Hardness: Choose models with thicker jaw plates and higher power for hard ore (Mohs hardness 7–10, e.g., granite, iron ore); standard models suit medium-hard materials (Mohs 5–6, e.g., limestone).

Production Capacity: Match the crusher’s output to your project’s daily ore processing requirements (e.g., PEV 600×900 for 50–150tph, PEV 900×1200 for 150–600tph).

Discharge Granularity: Select models with adjustable gaps to meet downstream processing needs (e.g., fine discharge for grinding, coarse discharge for aggregate).

Mining Environment: Compact models (e.g., PEV 400×600) for underground mines; large-scale models for open-pit operations with ample space.