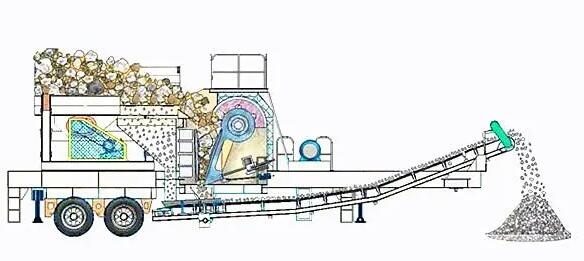

Hard Rock Mobile Crusher

CAPACITY

FEED SIZE

CAPACITY

FEED SIZE

Mobile jaw and cone crushing station, which includes feeding, crushing, screening, conveying and other functions, can solve various production problems in one stop. It is a tire-type mobile production line designed for small and medium production lines. It is suitable for Various hard rock crushing, screening, shaping and sand making operations.

Flexible mobility

The structure of the whole vehicle is compact, and it is convenient to change the site, enter and exit the site, and reduce the transportation cost of raw materials.

Customized

According to the different needs of customers and combined with the actual situation, various unit configurations are provided, which can be used for stand-alone operation or joint operation.

| Model | Ancillary equipment | Host equipment | Feed size (mm) | Capacity (tph) | Overall ability (tph) | Dimensions (mm) |

|---|---|---|---|---|---|---|

| XPEV69-1 | ZGC1038 | PEV600*900 | ≤500 | 100-180 | ≤100-220 | 13560*2890*4930 |

| XPEV75-1 | ZGC1238 | PEV750*1060 | ≤630 | 100-300 | ≤120-330 | 15340*2920*5370 |

| Model | Ancillary equipment | Host equipment | Feed size (mm) | Capacity (tph) | Overall ability (tph) | Dimensions (mm) |

|---|---|---|---|---|---|---|

| XHP200 | 3YK2160 | XHP200 | 70-190 | - | ≤70-220 | 14640*2920*6470 |

| XHP300 | 3YK2470 | XHP300 | 80-200 | - | ≤120-380 | 14790*3050*6660 |

| Model | Ancillary equipment | Host equipment | Feed size (mm) | Capacity (tph) | Overall ability (tph) | Dimensions (mm) |

|---|---|---|---|---|---|---|

| VSI-9532 | 2YK2470 | VSI9532 | ≤40 | 150-220 | ≤180-250 | 14970*2920*7595 |

| VSI-8522 | 2YK2160 | VSI8522 | ≤40 | 100-120 | ≤100-150 | 14500*2800*7200 |