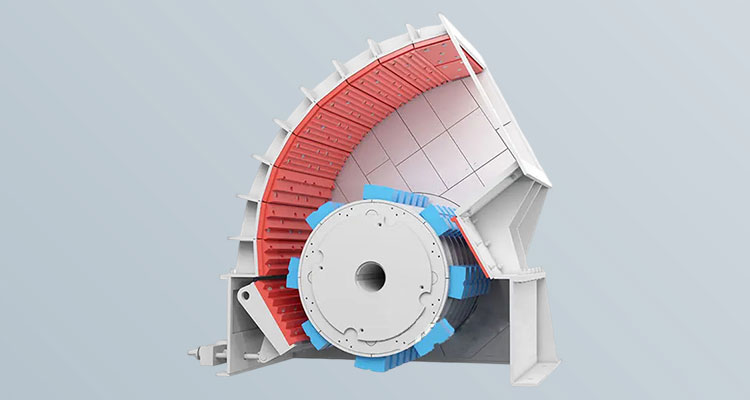

Heavy Hammer Crusher

CAPACITY

FEED SIZE

CAPACITY

FEED SIZE

XGN-Z series heavy hammer crusher is a new type of heavy hammer crusher developed according to user feedback information and the development trend of the crushing industry. When the physical properties of the mineral material are suitable, it can directly replace the jaw crusher and impact crusher.

Large feed size

The feed particle size can reach 1600mm, the crushing ratio is high, and the output can reach 3000 tons per hour.

No grate design

With an output of less than 600 tons per hour, it can be formed in one crush, effectively replacing the jaw crusher and impact crusher, with an output of 1,500 tons per hour.

Low powder yield

The unique self-flow groove design of the live liner, the qualified materials whose diameter is smaller than the gap are automatically discharged, reducing the repeated crushing of materials and reducing the powder output rate.

Alloy Composite Hammer

Focus on the research and development and production of crusher hammer heads, wear-resistant parts are all produced by our own foundry, and strictly control the quality of accessories. The unique patented technology of rotor disk wear-resistant retaining ring prolongs the life of the rotor.

| Model | Rotor diameter*length (mm) | Feed port width*length (mm) | Feed size (mm) | Capacity (tph) | Motor power (kw) | Dimensions (mm) |

|---|---|---|---|---|---|---|

| XGN-Z1310 | 1310*1050 | 890*1075 | ≤650 | 150-180 | 160 | 2950*2250*2495 |

| XGN-Z1512 | 1500*1160 | 1200*900 | ≤750 | 250-320 | 160*2 | 3260*2624*2750 |

| XGN-Z1513 | 1500*1350 | 1290*900 | ≤750 | 300-350 | 180*2 | 3260*2624*2750 |

| XGN-Z1615 | 1650*1452 | 1500*1200 | ≤1000 | 420-500 | 220*2 | 3667*2937*3436 |

| XGN-Z1818 | 1850*1800 | 1500*1280 | ≤1200 | 570-670 | 250*2 | 3680*3350*3515 |

| XGN-Z1620 | 1660*1900 | 2000*1200 | ≤1200 | 800-1000 | 400*2 | 3667*3200*3436 |

| XGN-Z1820 | 1800*1964 | 2000*1200 | ≤1200 | 1000-1200 | 450*2 | 3700*3270*3515 |

| XGN-Z2225 | 2200*2485 | 2530*1560 | ≤1600 | 2000-3000 | 1250 | 4460*4565*4670 |

| XGN-Z3332 | 3300*3220 | 3300*1840 | ≤1800 | 4500-6000 | (1250kw-6)*2 | 6710*6122*6340 |