What Is an Apron Feeder? Core Definition & Purpose

How Does an Apron Feeder Work?

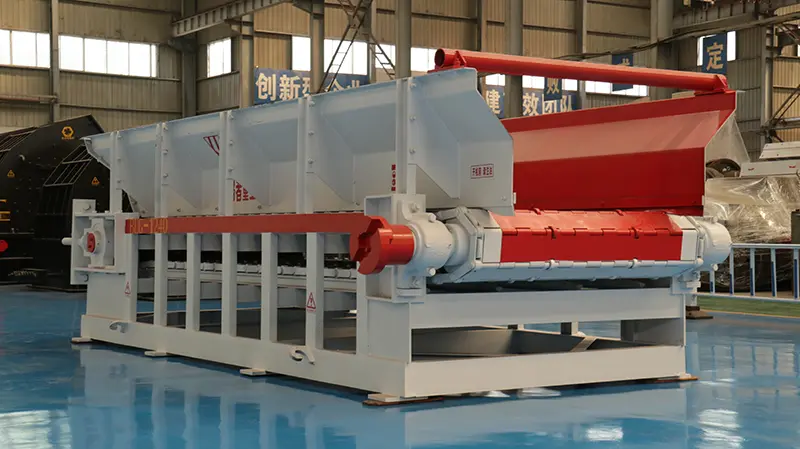

Material Loading: Bulk materials are discharged from a hopper or stockpile onto the overlapping pans of the apron feeder. The pans are designed to trap and support even large, irregularly shaped chunks.

Chain-Driven Movement: A motor-driven chain system (typically roller chains or pintle chains) pulls the pans along a fixed path. The chain is powered by a gearbox and motor, ensuring steady, adjustable speed (0.05–0.5 m/s).

Continuous Feeding: As the chain moves, the pans carry the material forward, delivering it evenly to the inlet of downstream equipment (e.g., jaw crusher, vibrating screen).

Material Discharge: At the end of the feeder’s path, the pans tilt slightly (or the chain turns) to discharge the material—completing the feeding cycle. The overlapping design of the pans prevents material spillage during transport.

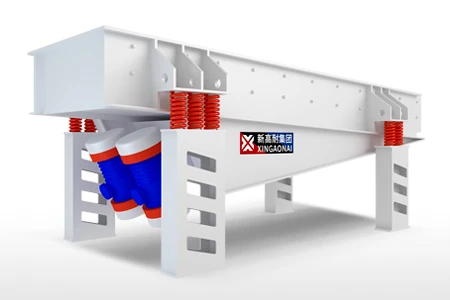

Key Components of an Apron Feeder

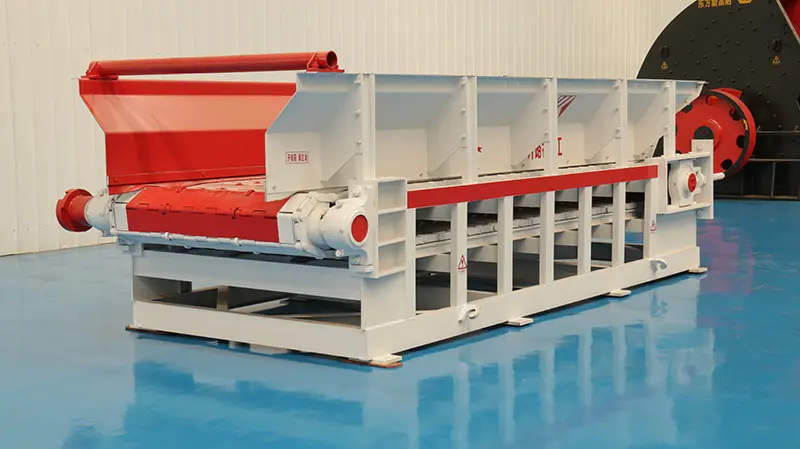

Pans/Plates: Made of high-strength steel (often manganese steel or wear-resistant alloy) to withstand impact and abrasion. Pans overlap to prevent material leakage.

Chain Drive System: Heavy-duty chains (roller, pintle, or cast link) that connect the pans and transmit power from the motor.

Motor & Gearbox: Provides the torque needed to move heavy loads. Variable frequency drives (VFDs) allow speed adjustment for precise feeding rates.

Frame: Rigid steel frame that supports the pans, chain, and drive system. Designed to absorb impact from falling materials.

Idlers & Rollers: Guide the chain and pans, reducing friction and ensuring smooth movement.

Guards & Covers: Protect operators and equipment from material spillage and moving parts, complying with safety standards.

Common Types of Apron Feeders

Heavy-Duty Apron Feeder: Designed for mining and quarry applications, handling large, abrasive materials (e.g., iron ore, granite boulders) weighing up to several tons per piece. Features thick, wear-resistant pans and reinforced chains.

Light-Duty Apron Feeder: Used for lighter materials (e.g., sand, limestone fines) in construction or cement plants. Compact design with thinner pans and smaller chains for cost-effectiveness.

Chain Apron Feeder: Characterized by cast link chains and deep pans, ideal for wet, sticky materials (e.g., clay, coal) that require extra support to prevent clogging.

Mobile Apron Feeder: Mounted on a mobile chassis for on-site material feeding in construction or temporary mining projects, offering flexibility in placement.

Industrial Applications of Apron Feeders

Mining: Feeds ore (iron, copper, coal) from stockpiles to crushers or grinding mills, handling heavy, abrasive materials 24/7.

Quarries: Transports limestone, granite, or gravel from hoppers to crushing and screening equipment, ensuring consistent production.

Construction: Feeds aggregates (sand, gravel) to concrete mixers or asphalt plants, supporting large-scale building projects.

Cement Manufacturing: Delivers limestone, clay, and other raw materials to kilns and grinders, maintaining continuous production.

Waste Recycling: Handles construction waste (concrete, brick) or industrial bulk waste, feeding it to recycling crushers.

Key Advantages of Apron Feeders

Handles Heavy & Abrasive Materials: Capable of supporting large, sharp, or abrasive materials that would damage belt conveyors or screw feeders.

Continuous & Precise Feeding: Adjustable speed controls ensure a consistent material flow, preventing overloads and optimizing downstream processing.

Durability & Longevity: Robust steel components and wear-resistant materials withstand harsh industrial environments, reducing maintenance and replacement costs.

Spillage Prevention: Overlapping pans and enclosed design minimize material leakage, keeping work areas clean and reducing waste.

Adaptability: Works with wet, sticky, or irregularly shaped materials that clog other feeders, making it versatile across industries.