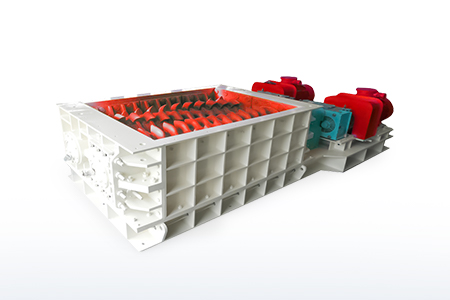

What Is a Custom Double Toothed Roller Crusher by Xingaonai?

Xingaonai’s custom double toothed roller crusher is built for medium-hard and brittle materials, including coal, limestone, gypsum, shale, and ore. Its robust structure and tailored design ensure stable operation, uniform particle size, and low wear—critical for long-term industrial productivity.

Core Customizations of Xingaonai Double Toothed Roller Crusher

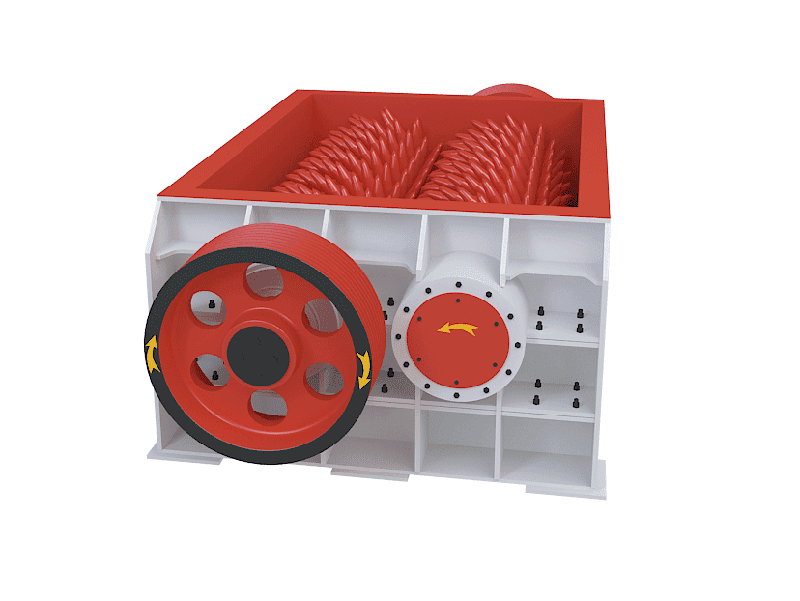

1. Roller Design & Tooth Customization

Tooth Shape: Sharp teeth for brittle materials (e.g., coal), blunt teeth for abrasive materials (e.g., limestone), or serrated teeth for sticky materials—preventing clogging and improving crushing efficiency.

Roller Size: Adjustable diameter (200–1200mm) and length (300–2000mm) to match production capacity (5–500 TPH) and feed size (up to 300mm).

Speed Ratio: Customizable roller rotation speed (50–300 rpm) to control crushing intensity—higher speed for finer output, lower speed for coarse crushing.

2. Material & Durability Customization

Roller Material: High-chromium alloy steel for abrasive materials, stainless steel for corrosion-resistant needs, or rubber-lined rollers for fragile materials (e.g., chemical raw materials).

Frame Structure: Reinforced cast steel or welded steel frame—tailored to withstand dynamic loads for large-scale operations or compact design for space-constrained sites.

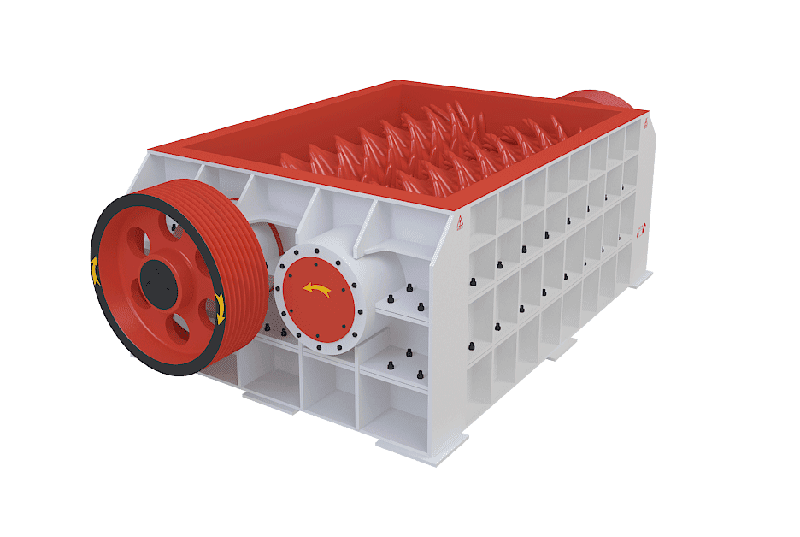

3. Operational & Control Customization

Drive System: Electric motor with variable frequency drive (VFD) for adjustable speed, or hydraulic drive for heavy-duty applications—reducing energy consumption by 10–15%.

Intelligent Controls: PLC control system with real-time monitoring of roller temperature, load, and wear—enabling automated operation and predictive maintenance.

Safety Features: Custom safety guards, overload protection, and emergency stop systems—compliant with international safety standards (CE, ISO).

Key Advantages of Xingaonai Custom Double Toothed Roller Crusher

1. Perfect Fit for Specific Needs

2. High Crushing Efficiency & Uniform Output

3. Durable & Low Maintenance

4. Energy-Saving & Eco-Friendly

5. Versatile Applications

Mining: Crushes coal, iron ore, and limestone for mineral processing.

Coal Processing: Crushes raw coal into graded coal for power generation or coking.

Building Materials: Processes shale, gypsum, and cement clinker for brick, tile, and cement production.

Chemical Industry: Crushes chemical raw materials (e.g., phosphate rock, gypsum) with corrosion-resistant or contamination-free designs.

Waste Recycling: Crushes construction waste (e.g., concrete, brick) into recycled aggregates—supporting sustainability.

Xingaonai’s Customization Process: From Consultation to Delivery

Needs Assessment: The team conducts in-depth consultations to understand your material properties, production capacity, output size, site space, and budget.

Material Testing: On-site or laboratory testing of raw materials to determine hardness, moisture content, and crushability—guiding customization decisions.

Design & Engineering: R&D engineers design the crusher with tailored parameters, providing 3D models and technical drawings for your approval.

Manufacturing & Quality Control: Production follows strict ISO standards, with inspections of key components (rollers, frame, drive system) to ensure quality.

Delivery & Installation: Global delivery with on-site installation, commissioning, and operator training.

After-Sales Support: 24/7 technical support, genuine spare parts supply, and regular maintenance guidance—ensuring long-term stable operation.

Success Stories: Xingaonai Custom Double Toothed Roller Crusher in Action

A coal mining company in Indonesia partnered with Xingaonai for a custom crusher with sharp teeth and VFD drive—increasing coal crushing efficiency by 25% and reducing energy costs.

A building materials plant in Germany selected a compact, corrosion-resistant custom model for shale crushing—fitting into limited site space while meeting strict environmental standards.

A chemical manufacturer in China chose a rubber-lined custom crusher for fragile chemical raw materials—ensuring no contamination and uniform particle size.