Jaw crushers and impact crushers are two of the most widely used crushing equipment in mining, aggregate production, and construction industries. While both are designed to reduce large rocks and materials into smaller particles, their working principles, performance characteristics, and ideal applications differ significantly. Understanding the differences between jaw crusher vs impact crusher is critical for plant managers, engineers, and procurement teams to select the right equipment for their specific needs—whether for primary crushing, secondary processing, or producing high-quality aggregates. This guide breaks down the core comparisons and offers actionable selection advice.

Core Working Principles: Jaw Crusher vs Impact Crusher

The fundamental distinction between a jaw crusher and an impact crusher lies in their crushing mechanisms, which directly shape their performance and material suitability:

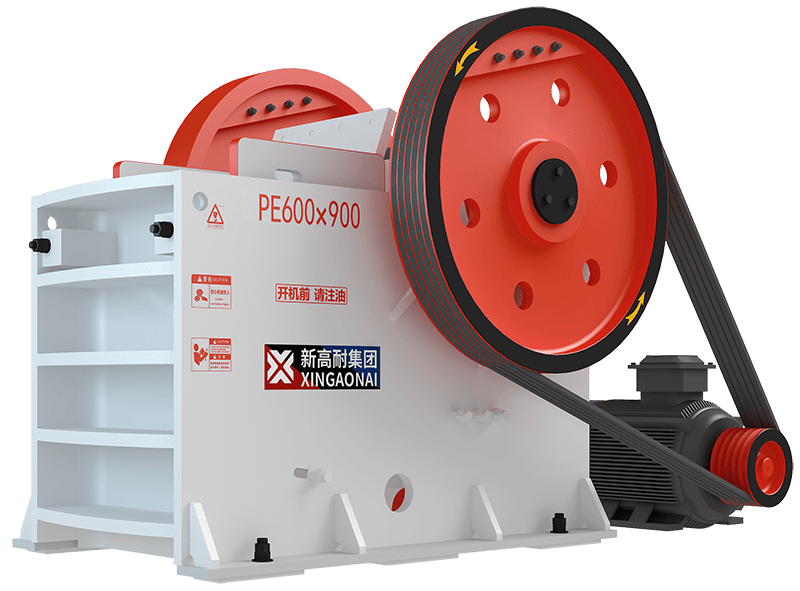

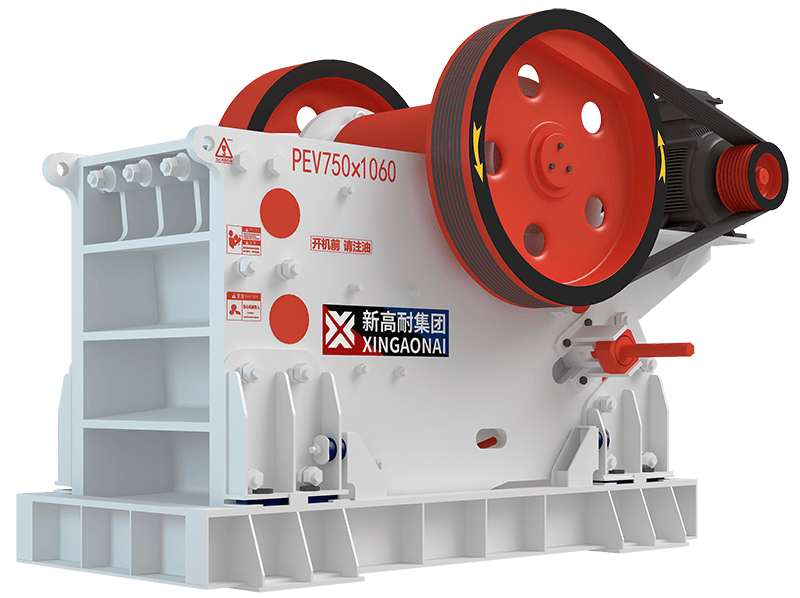

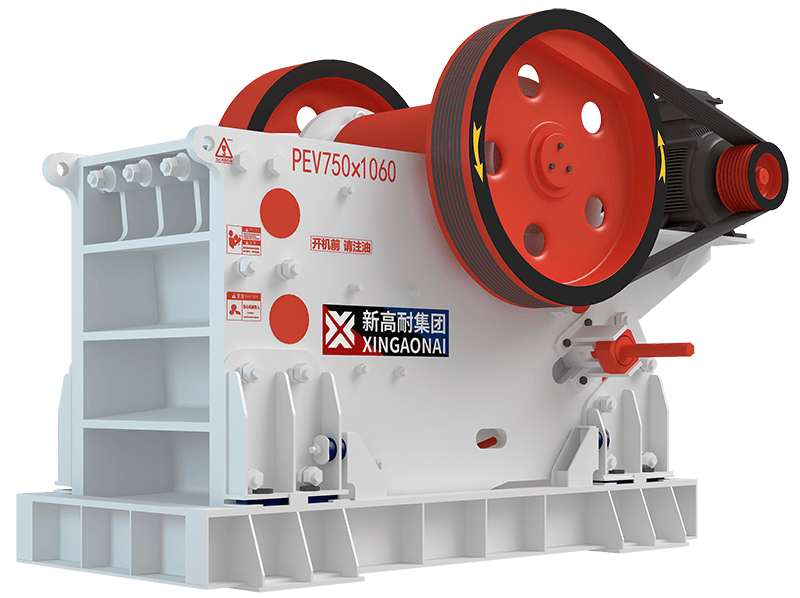

Jaw Crusher Working Principle

A jaw crusher operates on the principle of compressive force. It features a fixed jaw plate and a movable jaw plate that moves back and forth (driven by an eccentric shaft). Raw materials are fed into the crushing chamber, where the movable jaw squeezes and crushes them against the fixed jaw until they reach the desired size and fall through the discharge opening. This design is ideal for hard, abrasive materials, as compressive crushing minimizes wear on components.

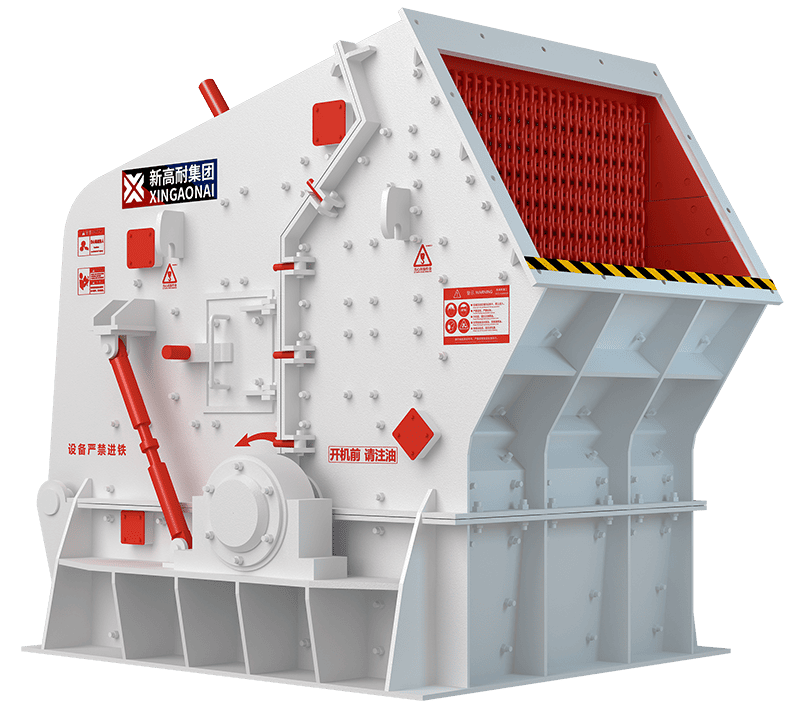

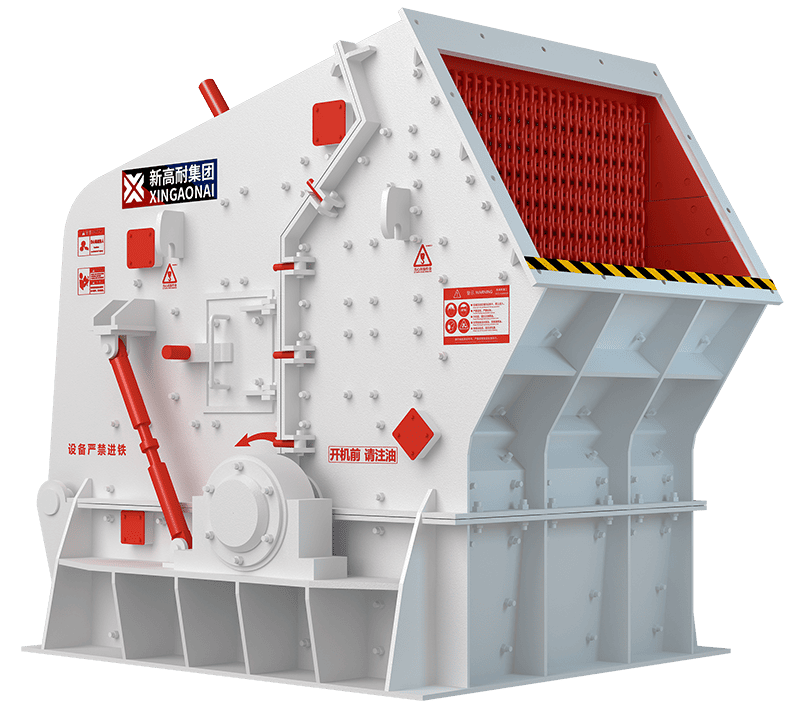

Impact Crusher Working Principle

An impact crusher relies on impact and shear force for crushing. It uses high-speed rotating blow bars to strike materials, which then rebound off the chamber’s impact plates and collide with other particles (shock crushing). This multi-stage impact process breaks materials into smaller, well-shaped particles. Impact crushers are more effective for brittle materials, as the impact force easily shatters them without excessive wear.

Key Comparison Dimensions: Jaw Crusher vs Impact Crusher

1. Suitable Materials & Hardness

Jaw Crusher: Excels at processing hard, abrasive materials with Mohs hardness 6–10 (e.g., granite, basalt, iron ore, quartz). It handles wet, sticky materials better than impact crushers, as its compressive crushing mechanism avoids clogging from moisture buildup.

Jaw crushers are the go-to choice for primary crushing of tough, high-density rocks.

Impact Crusher: Optimized for medium-soft, brittle materials with Mohs hardness ≤6 (e.g., limestone, dolomite, concrete debris, coal). It struggles with hard, abrasive materials, as blow bars and impact plates wear quickly—leading to frequent replacements and increased maintenance costs. Impact crushers are ideal for secondary or tertiary crushing of non-abrasive materials.

2. Crushing Stages & Particle Shape

Jaw Crusher: Primarily used as a primary crusher to reduce large raw materials (up to 1.5m in size) into coarse aggregates (10–100mm). The resulting particles have irregular, angular shapes due to compressive crushing—suitable for applications where particle shape is not a strict requirement (e.g., road base, fill materials).

Impact Crusher: Used as secondary or tertiary crusher to process pre-crushed materials into fine, well-graded aggregates (0–50mm). The impact crushing process produces cubical particles with smooth edges, making them ideal for high-quality concrete, asphalt, and architectural aggregates—where particle shape directly affects product strength and workability.

3. Production Capacity & Efficiency

Jaw Crusher: Offers high throughput (10–1,000 t/h) for large-scale operations. Its simple structure ensures stable operation and low energy consumption per ton of material. Jaw crushers maintain consistent capacity even when processing hard materials, making them suitable for continuous, high-volume production lines.

Impact Crusher: Capacity ranges from 5–500 t/h, generally lower than jaw crushers for the same size. It has higher energy consumption due to the high-speed rotating components, but delivers faster crushing cycles for brittle materials. Impact crushers also allow adjustable discharge size via changing the gap between impact plates—offering greater flexibility for fine crushing.

4. Maintenance & Durability

Jaw Crusher: Features a robust, simple design with few moving parts. Wear components (jaw plates) are made of high-manganese steel or alloy steel, offering long service life (3–6 months). Maintenance involves regular lubrication, jaw plate replacement, and eccentric shaft checks—low cost and minimal downtime.

Impact Crusher: Has more wear-prone components (blow bars, impact plates, liners) that require frequent replacement (1–3 months) when processing abrasive materials. The rotating assembly and bearing system also need regular inspection and lubrication. Overall maintenance costs are higher, but modern models with modular design simplify part replacement.

5. Installation & Space Requirements

Jaw Crusher: Requires a solid foundation due to its heavy weight and high vibration during operation. It has a vertical, compact structure that takes up less horizontal space, making it suitable for mines and quarries with limited floor space. Installation involves securing the base, connecting the drive system, and adjusting the discharge gap.

Impact Crusher: Has a larger footprint due to its horizontal crushing chamber and rotating components. It requires less foundation reinforcement than jaw crushers (lower vibration), but needs more horizontal space for installation. Some mobile impact crushers are available for on-site crushing, offering flexibility for construction waste recycling projects.

6. Cost: Initial Investment & Operational

Jaw Crusher: Higher initial investment due to its heavy-duty construction and durable components. However, lower maintenance costs, longer service life, and energy efficiency reduce long-term operational costs—making it cost-effective for long-term, high-volume projects.

Impact Crusher: Lower initial investment compared to jaw crushers of similar capacity. But higher maintenance costs (wear parts replacement), energy consumption, and shorter service life of components increase long-term costs—best for short-term projects or applications with non-abrasive materials.

Jaw Crusher vs Impact Crusher: Which to Choose?

The choice between a jaw crusher and an impact crusher depends on your project’s specific requirements:

Choose a Jaw Crusher If: You need primary crushing of hard, abrasive materials; prioritize high throughput and low long-term costs; or work with wet/sticky materials. Ideal for mines, quarries, and large aggregate production lines.

Choose an Impact Crusher If: You need secondary/tertiary crushing for fine, cubical aggregates; process medium-soft, brittle materials; or require mobile on-site crushing. Perfect for concrete recycling, asphalt production, and architectural aggregate projects.

Key Additional Considerations

When selecting between jaw crusher vs impact crusher, also factor in:

Product Quality Requirements: Impact crushers deliver superior particle shape for high-end applications.

Material Moisture Content: Jaw crushers avoid clogging with wet materials.

Project Timeline: Impact crushers suit short-term projects; jaw crushers for long-term operations.

Transport & Mobility: Mobile impact crushers offer on-site flexibility; jaw crushers are mostly stationary.

Conclusion

Jaw crushers and impact crushers serve distinct roles in crushing operations. A jaw crusher is a reliable workhorse for primary crushing of hard materials, while an

impact crusher excels at producing high-quality, well-shaped aggregates from brittle materials. By evaluating your material properties, production goals, product requirements, and budget, you can select the equipment that optimizes efficiency, reduces costs, and meets project standards. Whether for mining, construction, or aggregate production, understanding the differences between jaw crusher vs impact crusher is key to maximizing operational success.