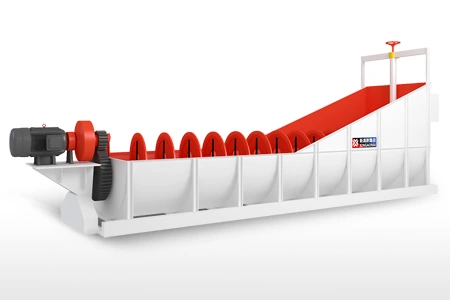

In aggregate production, mining, and construction industries, clean sand with minimal impurities is critical for producing durable concrete, asphalt, and building materials. A

screw sand washing machine (also called a spiral sand washer) is a widely used equipment for sand purification, leveraging a unique spiral agitation mechanism to efficiently separate dust, clay, and debris from sand particles. Understanding its working principle is key to optimizing operation, reducing material loss, and ensuring consistent product quality. Below is a detailed, step-by-step breakdown of how a

screw sand washing machine operates, along with key components and operational logic.

At its heart, a screw sand washing machine uses two key forces to clean sand: mechanical agitation from a rotating spiral blade and hydraulic separation from water flow. The spiral blade not only stirs sand to loosen surface impurities but also transports the cleaned sand upward for dehydration and discharge. Meanwhile, water acts as a medium to carry away lightweight impurities (e.g., dust, clay) through overflow—creating a seamless cycle of cleaning, separation, and collection. Unlike wheel sand washers, the spiral design excels at deep cleaning and handling high-moisture, high-viscosity sand, making it a preferred choice for demanding applications.

The operation of a screw sand washing machine follows a systematic, continuous process that ensures thorough cleaning without excessive sand loss. Here’s the detailed breakdown:

Crushed sand, natural river sand, or mineral sand is transported to the

screw sand washing machine’s feed hopper via a conveyor belt or vibrating feeder. The feed rate is controlled to match the machine’s processing capacity (typically 20-500 t/h), ensuring the sand is evenly distributed into the inclined water tank. Overfeeding is avoided to prevent clogging and ensure each sand particle comes into full contact with water and the spiral blade.

Once inside the water tank, the motor drives the reducer, which rotates the spiral shaft (equipped with continuous, wear-resistant blades) at a steady speed (8-15 rpm). As the spiral blade rotates:

It agitates the sand vigorously, creating friction between particles to loosen adhered dust, clay, and organic impurities.

The inclined angle of the spiral (usually 15-20°) ensures the sand is constantly turned over, exposing all surfaces to water for thorough cleaning.

Water is continuously injected into the tank to maintain a stable water level—submerging the sand partially to facilitate impurity separation.

Lightweight impurities (e.g., dust, clay particles, and organic matter) have lower density than sand. As the spiral blade stirs the mixture:

These impurities float to the water surface and are carried away by the overflow channel built into the upper part of the tank.

The overflow water is often directed to a sedimentation tank for recycling, reducing water waste and environmental impact.

Heavier sand particles (with higher density) remain at the bottom of the tank, continuing to be agitated and cleaned by the spiral blade.

After thorough cleaning, the spiral blade’s spiral structure acts as a conveyor—gradually lifting the clean sand upward along the inclined tank. During this upward transport:

Excess water drains back into the tank through gaps between the spiral blades, achieving preliminary dehydration.

The sand passes through a dewatering section (near the discharge port) where residual water is further removed, resulting in clean sand with a moisture content of 8-12% (ideal for immediate use or storage).

The dehydrated, clean sand is finally discharged from the top outlet of the screw sand washing machine onto a conveyor belt or storage bin. The entire process is continuous, with no interruptions between feeding, cleaning, separation, and discharge—ensuring high production efficiency for large-scale sand processing lines.

To fully grasp the screw sand washing machine’s working principle, it’s essential to understand its core components and their roles:

Spiral Shaft & Blades: The "heart" of the machine—made of high-manganese steel or rubber-lined material for wear resistance. The spiral shape enables both agitation and conveying.

Water Tank: A durable steel tank that holds water and sand during cleaning; designed with an overflow channel and sloped bottom to optimize separation.

Motor & Reducer: Provide stable power for spiral rotation, with adjustable speed to adapt to different sand types and cleaning requirements.

Feed Hopper & Discharge Chute: Ensure smooth material flow in and out, preventing blockages and minimizing sand loss.

Support Frame: Maintains the machine’s inclined angle (critical for conveying and dehydration) and ensures stability during high-load operation.

The unique working principle of the screw sand washing machine delivers distinct benefits for sand processing:

Deep Cleaning Effect: Intense spiral agitation removes 98%+ of impurities, including stubborn clay and dust, producing high-purity sand.

Low Sand Loss: The spiral’s gentle conveying minimizes sand particle breakage and loss—sand recovery rate exceeds 95%.

Energy & Water Efficiency: The continuous process requires less energy than batch-type washers; recycled water use reduces consumption by 30-50%.

Adaptability: Handles high-moisture, high-viscosity sand (e.g., river sand, construction waste sand) that other washers may struggle with.

Smooth Operation: Simple mechanical structure reduces vibration and noise, ensuring stable, long-term operation with minimal maintenance.

Aggregate Production Lines: Cleaning crushed stone sand, gravel, and natural sand for highways, bridges, and building projects.

Mining Beneficiation: Purifying mineral sand (e.g., quartz sand, feldspar sand) to improve mineral concentration.

Construction Waste Recycling: Cleaning concrete and brick debris to produce recycled sand for secondary use.

Water Conservancy Projects: Cleaning sand for dam construction, river dredging, and coastal reclamation.

Glass & Ceramic Manufacturing: Producing high-purity sand for glass melting and ceramic raw material processing.