1. Core Mechanics of the Rod Mill Working Principle

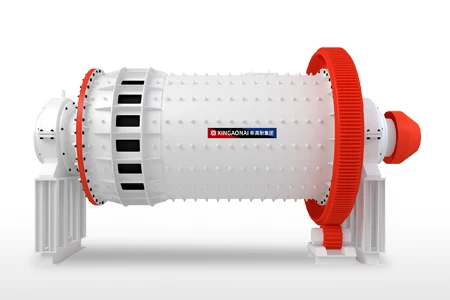

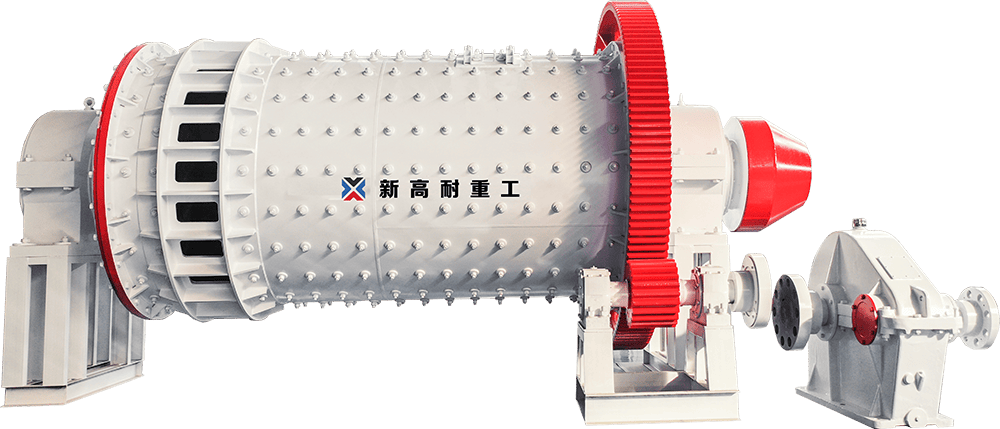

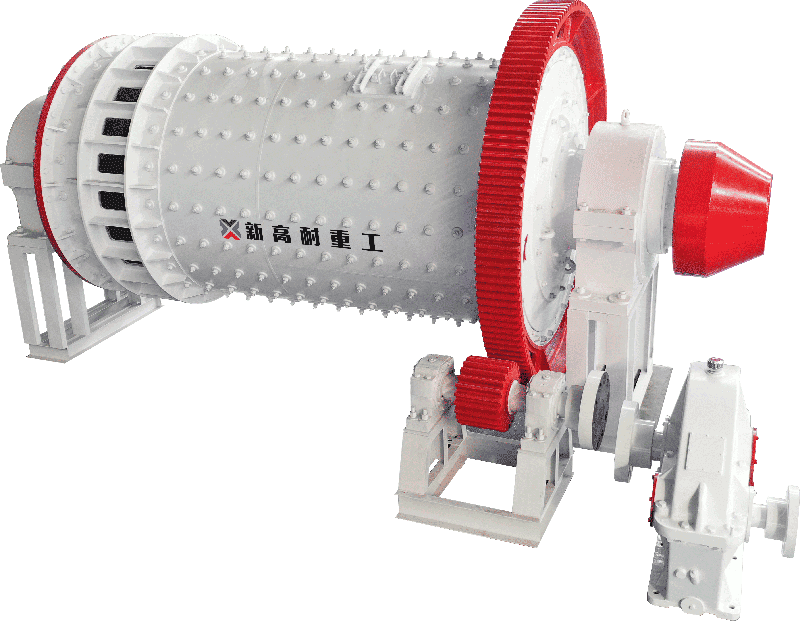

Grinding Media Movement: When the rod mill’s horizontal cylinder rotates (at a speed of 20-30 RPM, optimized for the rod mill working principle), the steel rods inside lift under centrifugal force and gravity. As the cylinder turns, the rods fall, roll, and slide, creating a continuous grinding action.

Material Interaction: Raw materials (pre-crushed to 20-30mm) enter the cylinder through the feeding end. As the rods move, they exert impact force on the materials, while friction between rods and materials (and between materials themselves) grinds particles into the desired size.

Graded Grinding: The steel rods are arranged by length (longer rods at the feeding end, shorter at the discharge end), which aligns with the rod mill working principle of progressive grinding—coarse materials are crushed first, then refined into fine sand as they move toward the discharge end.

2. Structural Components Supporting the Rod Mill Working Principle

Horizontal Cylinder: The main body of the rod mill, made of thick steel plates to withstand impact and wear. Its rotation speed is critical to the rod mill working principle—too fast, and rods stick to the cylinder wall (no grinding); too slow, and rods don’t lift enough (insufficient impact).

Steel Rods: The grinding media, typically made of high-chromium alloy steel for durability. Rod diameter (50-100mm) and length are selected based on the rod mill working principle and material hardness (thicker rods for hard materials like granite).

Feeding Device: Ensures uniform material feeding, a key part of the rod mill working principle—uneven feeding causes overloading or underutilization of grinding space. Common types include spiral feeders and chute feeders.

Discharge Device: Controls the particle size of the finished product. Grate discharge devices retain coarse particles for re-grinding (aligning with the rod mill working principle of uniform output), while overflow discharge is used for finer sand requirements.

Drive System: Powers the cylinder rotation, including a motor, reducer, and gear/belt drive. Stable speed control is essential for the rod mill working principle, as inconsistent rotation disrupts grinding efficiency.

3. Operational Process: How the Rod Mill Working Principle Translates to Production

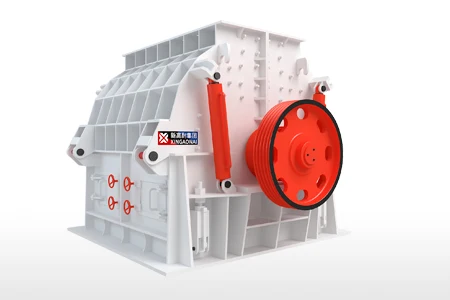

Material Preparation: Raw materials (limestone, granite, river pebbles, etc.) are crushed to 20-30mm by a jaw crusher or cone crusher—this pre-processing aligns with the rod mill working principle, as the mill is designed for secondary grinding, not primary crushing.

Feeding: The pre-crushed materials are fed into the rod mill’s cylinder through the feeding device, which distributes them evenly across the grinding chamber.

Grinding Stage: As the cylinder rotates, the steel rods lift and fall, crushing and grinding the materials. The rod mill working principle’s linear contact between rods and materials reduces over-crushing, producing sand with a regular shape.

Classification & Discharge: Finished particles (usually 0-5mm) pass through the discharge device, while unqualified coarse particles are retained for further grinding. Some production lines integrate a vibrating screen to separate fine sand from coarse particles, looping the latter back to the rod mill—enhancing the rod mill working principle’s efficiency.

Dust & Noise Control: During operation, dust collectors and noise reduction devices (part of modern rod mill designs) minimize environmental impact, without affecting the rod mill working principle.

4. Key Factors Influencing the Rod Mill Working Principle

Rod Mill Speed: As mentioned, the rotation speed directly impacts the rod mill working principle. Manufacturers typically set the optimal speed based on cylinder diameter (e.g., 24 RPM for a 2.2m diameter cylinder).

Rod Load & Arrangement: The weight of steel rods (30-45% of the cylinder volume) and proper arrangement (no overlapping) are vital to the rod mill working principle—insufficient rod load reduces grinding efficiency, while overloading causes excessive wear.

Material Properties: Hardness, moisture, and particle size of raw materials affect the rod mill working principle. High-moisture materials may stick to rods, so pre-drying is recommended; soft materials require thinner rods to avoid over-grinding.

Feed Rate: Uniform, consistent feeding ensures the rod mill working principle’s grinding chamber is fully utilized. Adjust the feed rate based on the mill’s capacity (5-100 t/h) to avoid underfeeding or overfeeding.

5. Why the Rod Mill Working Principle Stands Out for Sand Making

Uniform Particle Size: The linear grinding action of the rod mill working principle minimizes fine powder content, resulting in sand with continuous gradation—ideal for concrete and mortar.

Good Particle Shape: The rolling and grinding motion of steel rods produces rounder sand particles, enhancing the strength and workability of building materials.

Energy Efficiency: The rod mill working principle’s targeted grinding reduces energy consumption compared to ball mills, especially for coarse-to-medium sand production.