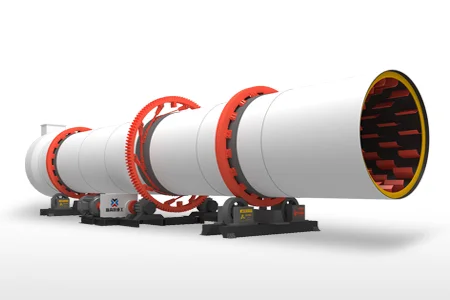

When exploring industrial drying solutions, one question frequently arises: what is a rotary dryer? Simply put, a rotary dryer is a large-scale, continuous industrial machine designed to remove moisture from bulk solids, powders, or granular materials. It is widely recognized for its efficiency, versatility, and ability to handle high-volume processing, making it a cornerstone in sectors ranging from mining to agriculture. At its essence, a rotary dryer is a cylindrical device that uses heat transfer to reduce the moisture content of materials. Unlike batch dryers that process small quantities at a time, rotary dryers operate continuously, making them ideal for large-scale production lines. The primary goal of a rotary dryer is to transform wet, sticky, or damp materials into dry, flowable products that meet quality standards for storage, transportation, or further processing. Whether drying coal, agricultural grains, mineral ores, or chemical powders, the rotary dryer achieves consistent moisture reduction through controlled heat and material movement.

To understand “what is a rotary dryer” beyond its basic definition, it’s critical to examine its working principle. The process relies on three key elements: heat transfer, material movement, and moisture evaporation. Here’s a step-by-step breakdown:

Material Feeding: Wet materials are fed into one end of the rotating cylindrical drum (typically inclined at a slight angle to facilitate movement).

Heat Application: Hot air (or another heating medium, such as flue gas or steam) is introduced into the drum—either in the same direction as the material (co-current flow) or opposite direction (counter-current flow). Counter-current flow is often preferred for higher efficiency, as it maximizes heat-material contact.

Tumbling & Mixing: As the drum rotates, internal lifters (baffles) lift and drop the material, ensuring uniform exposure to the hot air. This tumbling action prevents clumping and promotes thorough drying.

Moisture Evaporation: Heat from the air transfers to the wet material, causing moisture to evaporate into the gas stream.

Discharge: Dry materials exit the opposite end of the drum, while moist air (carrying evaporated water) is vented or treated to remove contaminants before release.

This continuous, automated process is what sets rotary dryers apart—enabling them to handle thousands of tons of material daily while maintaining consistent drying results.

To further answer “what is a rotary dryer,” let’s explore its core components, which work together to ensure efficient operation:

Rotating Drum: The cylindrical shell (usually made of steel or stainless steel) is the heart of the dryer, ranging in length from 10 to 100 feet and diameter from 3 to 12 feet. Its slight incline (1-5 degrees) guides material through the drum.

Lifters/Baffles: Internal fins that lift and disperse material, maximizing heat contact and preventing stagnation.

Heat Source: Can include natural gas burners, coal-fired furnaces, electric heaters, or waste heat recovery systems—selected based on material type and energy efficiency goals.

Feeding & Discharging Systems: Hoppers, conveyors, or chutes that control material flow into and out of the drum.

Air Handling Equipment: Fans, ducts, and cyclones/filters that manage the hot air stream and capture dust or particles.

When asking “what is a rotary dryer,” it’s important to note that not all models are the same. The two primary types are distinguished by their heat transfer methods:

In direct-fired models, the heating medium (hot air) comes into direct contact with the material. This design offers high thermal efficiency and faster drying times, making it suitable for non-sensitive materials like coal, limestone, or construction aggregates.

Indirect-fired dryers separate the heating medium from the material—heat is transferred through the drum’s walls. This is ideal for materials that are flammable, dusty, or prone to contamination (e.g., food products, chemicals, or pharmaceuticals).

Other specialized variants include rotary drum dryers for sludge, sand, or biomass—each tailored to specific material properties.

A key part of answering “what is a rotary dryer” is highlighting its real-world uses. Thanks to its versatility, the rotary dryer is employed across numerous industries:

Mining & Minerals: Drying iron ore, copper concentrate, limestone, and coal to improve handling and processing efficiency.

Agriculture: Drying grains (wheat, corn, rice), seeds, and biomass (wood chips, straw) for storage and transportation.

Chemical Industry: Drying fertilizers, pigments, catalysts, and plastic resins to meet product specifications.

Construction Materials: Drying sand, cement, and concrete aggregates to enhance strength and workability.

Waste Management: Drying sewage sludge, industrial waste, and compost to reduce volume and facilitate disposal or recycling.

Why is the

rotary dryer such a popular choice? Its benefits directly address the needs of industrial operations:

High Capacity: Handles large volumes of material (up to 200 tons per hour), ideal for mass production.

Uniform Drying: Tumbling action and controlled heat ensure consistent moisture levels across all output.

Versatility: Adapts to diverse materials (wet, sticky, granular, powdery) and moisture content (from 10% to 80%).

Energy Efficiency: Advanced designs (e.g., counter-current flow, waste heat recovery) minimize energy consumption.

Low Maintenance: Robust construction and simple operating principle reduce downtime and repair costs.

As industrial demands for efficient, sustainable drying grow, rotary dryers continue to evolve—incorporating smarter controls, better insulation, and cleaner energy sources.