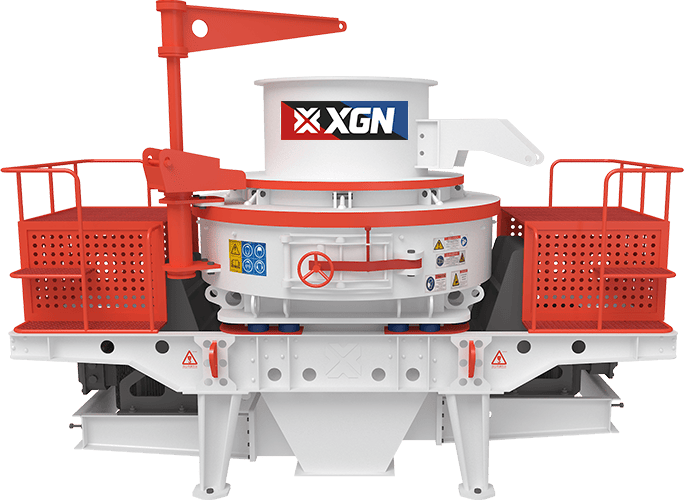

Common Issues Requiring VSI Series Impact Crusher Repair

Worn Impellers & Liners: The impeller (rotor) and crushing chamber liners are direct contact points with abrasive materials. Over time, they develop cracks, thinning, or uneven wear, leading to reduced crushing efficiency and uneven product size.

Excessive Vibration: Imbalanced rotors, loose fasteners, or uneven feed rates can cause abnormal vibration, risking damage to bearings and the machine frame.

Hydraulic System Failures: Hydraulic systems control rotor speed and discharge settings—leaks, low pressure, or faulty valves hinder operation and require prompt impact crusher repair.

Motor Overheating: Overloaded feeding, poor ventilation, or damaged wiring can cause the crusher’s motor to overheat, triggering shutdowns.

Poor Product Quality: Clogged discharge ports, worn impact anvils, or incorrect rotor speed result in inconsistent particle size, indicating the need for calibration or repair.

Key Steps for VSI Series Impact Crusher Repair

1. Wear Part Replacement (Impeller, Liners, Anvils)

Safety First: Shut down the crusher, disconnect power, and lock out the system to prevent accidental startup.

Inspection: Remove the crusher cover to examine the impeller, liners, and anvils for wear depth, cracks, or deformation. Replace parts that exceed manufacturer-specified wear limits.

Installation: Use genuine OEM parts for compatibility. Ensure the impeller is properly balanced (unbalanced rotors cause vibration) and liners/anvils are tightened to torque specifications.

2. Vibration Troubleshooting & Repair

Check Fasteners: Tighten loose bolts on the rotor, frame, and motor mounts. Loose components amplify vibration.

Rotor Balancing: If the rotor is imbalanced (often due to uneven wear), send it to a professional shop for dynamic balancing.

Adjust Feed Rate: Ensure uniform feeding to avoid overloading one side of the rotor, which causes uneven stress and vibration.

3. Hydraulic System Repair

Leak Detection: Identify leaks in hoses, cylinders, or valves. Replace damaged hoses and sealants.

Fluid Maintenance: Drain old hydraulic fluid, clean the reservoir, and refill with the manufacturer-recommended fluid grade. Check filters and replace if clogged.

Pressure Calibration: Use a pressure gauge to verify hydraulic pressure matches operational requirements. Adjust valves if pressure is too high or low.

4. Motor Overheating Repair

Cooling System Check: Clean dust and debris from the motor’s cooling fins to improve ventilation.

Load Reduction: Adjust the feed rate to avoid overloading the motor. Ensure the crushing chamber is not clogged with uncrushable materials.

Electrical Inspection: Check wiring for damage, loose connections, or corrosion. Repair or replace faulty components and ensure proper grounding.

Proactive Maintenance to Reduce Impact Crusher Repair Needs

Daily Inspections: Check for unusual noises, vibration, or fluid leaks. Clear debris from the crushing chamber and feed hopper.

Lubrication: Regularly lubricate the rotor bearings, hydraulic system, and moving parts with the correct lubricant grade. Poor lubrication accelerates wear.

Calibration: Periodically calibrate rotor speed, hydraulic pressure, and discharge settings to maintain product quality and efficiency.

Filter Replacement: Change air, oil, and hydraulic filters at manufacturer-recommended intervals to prevent contamination.

Training: Ensure operators are trained to recognize early warning signs (e.g., abnormal vibration, overheating) and follow proper operating procedures.

Important Considerations for Professional Impact Crusher Repair

Genuine Parts: Use OEM or certified replacement parts to ensure compatibility and performance. Generic parts may wear faster or damage the crusher.

Manufacturer Guidelines: Follow the manufacturer’s repair manual for procedures, torque specifications, and safety standards.

Professional Technicians: For major repairs (e.g., rotor replacement, hydraulic system overhaul), hire certified technicians with experience in VSI series crushers.

Warranty Compliance: Improper repair can void the equipment warranty—always consult the manufacturer before attempting major modifications.