What Is a Flotation Machine: Core Definition & Purpose

At its essence, a flotation machine is a vessel designed to create a froth layer that selectively carries valuable minerals to the surface for collection. Its primary purpose is to separate and concentrate valuable minerals from gangue (worthless rock) in ore, making it economically viable to refine metals. Unlike other separation methods, the flotation machine works even with fine-grained ore (down to 20μm), which is why it’s indispensable in modern mining. Whether processing gold ore, copper sulfides, or phosphate rock, the flotation machine turns low-grade raw material into high-value concentrates.

How Does a Flotation Machine Work?

Ore Preparation: Crushed and ground ore is mixed with water to form a slurry, which is fed into the flotation machine.

Reagent Addition: Chemical reagents (collectors, frothers, modifiers) are added to the slurry. Collectors coat valuable minerals to make their surfaces hydrophobic; frothers create stable bubbles; modifiers adjust the slurry’s pH to enhance separation.

Aeration & Agitation: The flotation machine injects air into the slurry, creating tiny bubbles. Simultaneously, an agitator keeps the slurry mixed, ensuring minerals come into contact with bubbles.

Froth Separation: Hydrophobic valuable minerals attach to the bubbles and rise to form a froth layer on the surface. The froth (rich in target minerals) is scraped off by mechanical paddles, while hydrophilic gangue remains in the slurry and is discharged as tailings.

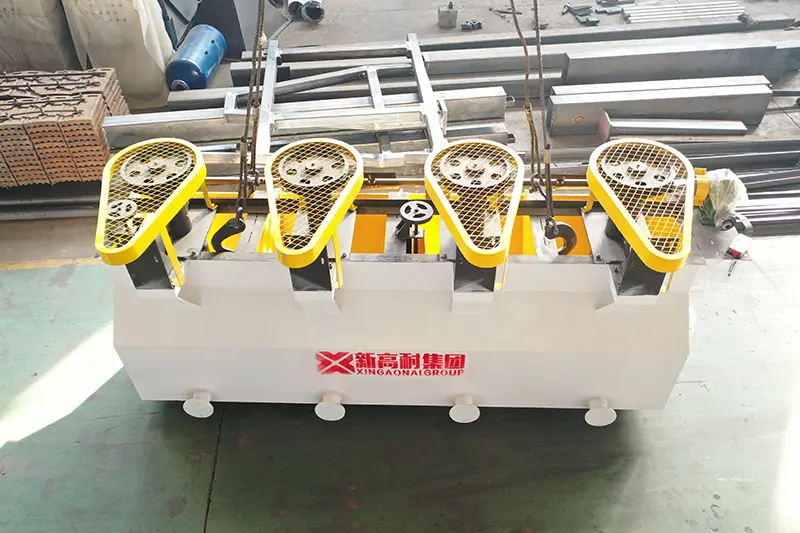

Core Components of a Flotation Machine

Flotation Cell (Vessel): The main tank where slurry, reagents, and air interact. It’s typically made of stainless steel or rubber-lined steel to resist corrosion.

Agitator: A rotating device that mixes the slurry, prevents mineral settling, and disperses air bubbles evenly.

Aeration System: Pipes or diffusers that inject air into the slurry, generating the bubbles needed for mineral attachment.

Froth Scrapers: Mechanical paddles that skim the mineral-rich froth from the surface and direct it to a collection trough.

Reagent Dosing System: Pumps and nozzles that precisely deliver collectors, frothers, and modifiers into the flotation cell.

Control Panel: Modern flotation machines feature PLC controls to adjust slurry level, air flow, and reagent dosage in real time.

Common Types of Flotation Machines

1. Mechanical Flotation Machine

2. Pneumatic Flotation Machine

3. Pneumomechanical Flotation Machine

4. Column Flotation Machine

Industrial Applications of Flotation Machines

Metal Mining: Separates gold, copper, lead, zinc, nickel, and platinum-group metals from ore. For example, copper sulfide ore is processed in flotation machines to produce copper concentrate (25-30% copper content) for smelting.

Non-Metallic Mineral Processing: Concentrates phosphate, fluorite, barite, and kaolin for use in fertilizers, ceramics, and construction materials.

Coal Preparation: Removes sulfur and ash from coal to meet environmental standards and improve combustion efficiency.

Wastewater Treatment: Separates oil, solids, and contaminants from industrial wastewater, supporting environmental compliance.

Key Advantages of a High-Quality Flotation Machine

High Separation Efficiency: Selectively concentrates valuable minerals, even from low-grade ore (as low as 0.5% copper or 1g/t gold).

Versatility: Handles diverse ore types (sulfides, oxides, carbonates) and particle sizes (20μm-2mm).

Scalability: Available in small lab-scale models (1-5 L) and large industrial units (500+ m³/h), adapting to production needs.

Precision Control: Modern models with automated systems allow precise adjustment of process parameters, ensuring consistent concentrate quality.

Cost-Effectiveness: Turns low-value ore into profitable concentrates, maximizing the economic value of mining projects.

How to Choose the Right Flotation Machine?

Ore Properties: Choose the type (mechanical, pneumatic) based on mineral surface properties, particle size, and ore hardness.

Production Capacity: Match the flotation machine’s volume to your daily throughput requirements.

Concentrate Quality Goals: Opt for column flotation machines if high-purity concentrates are needed.

Energy Efficiency: Prioritize models with low power consumption, especially for large-scale operations.

Maintenance Needs: Select machines with durable components and easy access for cleaning and part replacement.